Applications

- Other temporary plugging operations.

- Completion casing open hole layered sectioned fracturing construction.

- Mainly used in vertical or horizontal well casings for layered section fracturing.

Features

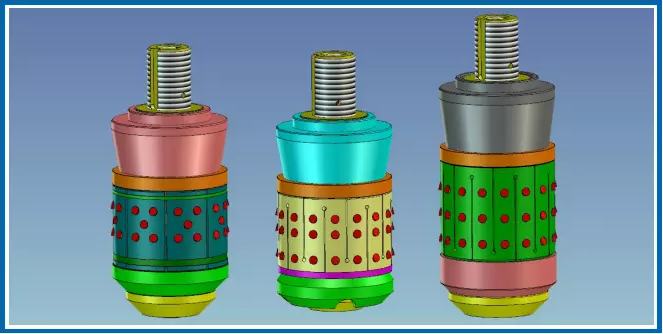

The structure is simple and user-friendly, offering various specifications—Φ72, Φ85, Φ88, Φ98, Φ102, and Φ108—to accommodate staged fracturing requirements for different well diameters.

- High Compressive Strength: Designed to withstand operations in medium and deep wells, with all components, including sealing parts, made from degradable materials that leave no residue after dissolution.

- Specialized Fracturing Bridge Plug: Equipped with a central production channel, allowing direct production after fracturing. The plug fully dissolves in wellbore fluid, eliminating the need for drilling.

- Compact Design: Features a short body length and minimal seat-seal displacement.

- Enhanced Performance: Compared to rubber-tube-sealed soluble bridge plugs, it offers better temperature adaptability—performing well in both lower and higher temperature ranges—and ensures thorough dissolution post-construction.

- Drillability: In special cases where removal is required, the plug can be efficiently drilled out using standard high-performance milling tools.

- Adaptability in Non-Water Environments: For non-water operation wells, the plug can be used alongside acidic rapid-degradation fluids.

Working Principle

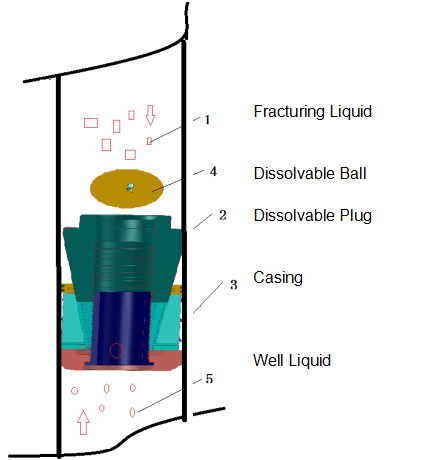

The Wingoil all-metal dissolvable frac bridge plug is a temporary isolation frac plug designed and manufactured using water-soluble materials. It consists of components such as a throwaway screw, top wire, ceramic column, O-ring, sealing ring, lower support, slips, and take-off ring.

1. Installation:

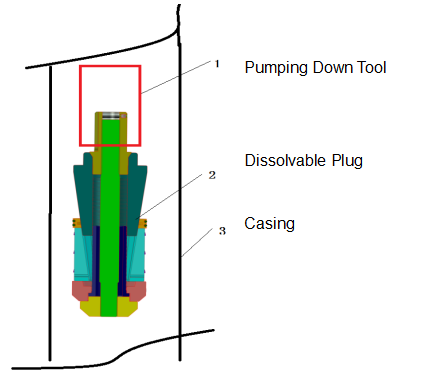

The plug is attached to the adapter of the plug-feeding tool using the throwaway screw. It is then delivered to the designated setting position via cable or coiled tubing.

2. Positioning and Activation:

Once positioned using CCL calibration, the plug is activated either by igniting the plug-feeding tool or by pumping liquid from the surface. The generated gas pressure from a gunpowder column or hydraulic pressure from the pumped liquid pushes the vertebral body. The take-off ring restricts the movement of the mandrel, allowing relative displacement between the mandrel and vertebral body.

- The vertebral body moves downward, pushing the sealing ring and slip cone.

- The sealing ring deforms under thrust, expanding to seal the sleeve’s inner cavity while the inclined surface of the slips extends outward.

- The slips bite into the casing’s inner wall to ensure anchoring.

3. Setting and Disconnection:

When the applied thrust reaches 120-130 KN or higher, the plug is fully set and anchored. The mandrel of the plug-feeding tool is then disengaged by disconnecting the hand-off screw, allowing the plug-feeding tool to be retrieved.

4. Fracturing Operation:

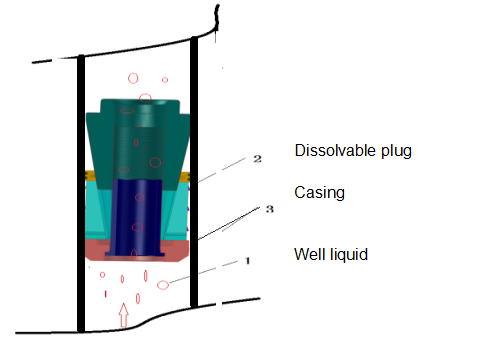

After setting, the inner cavity of the plug is sealed by an inserted sphere, creating a one-way flow channel. Fluid can only flow upward from the bottom, while the upper fluid is blocked, ensuring the bridge plug remains sealed during fracturing.

5. Post-fracturing:

Once fracturing is completed, fluid from the lower interval flows through the one-way channel for normal blasting or production. During this process, the Wingoil all-metal dissolvable bridge plug degrades and dissolves in the wellbore fluid, leaving no residue.

Operation Manual

- Before deploying the bridge plug for plugging operations, ensure the wellbore is thoroughly cleaned, scraped, and cleaned to guarantee unobstructed flow.

- Inspect the assembly of the plug-feeding tool carefully prior to lowering it into the well. All connections must be secure, and the outer cylinder of the tool should fully abut the mandrel shoulder.

- When lowering the tool using a pipe string or cable, maintain a controlled speed not exceeding 30 m/min. Sudden lifting, abrupt release, or strong impacts are strictly prohibited. If pumping is used, the recommended displacement is 1.8–2 m³/min.

- For staged fracturing wells, accurately measure the displacement to ensure the complete removal of sand from the casing in the plugging section.

- During hydraulic plug-feeding operations, increase the pump injection pressure incrementally in 5 MPa steps, pausing for one minute at each step to achieve stable setting.

Operation Precautions

- Store the tool in a cool, dry environment.

- During transportation, ensure it is securely placed in a protective box, avoiding any strong collisions.

- Do not use the tool if there is any local deformation or abnormality on its outer surface.

- The bridge plug must not be deployed until the wellbore sand has been thoroughly cleaned following fracturing sand plugging.

- In the event of abnormal conditions during horizontal well pumping, analyze the cause. If early setting is ruled out, adjust the displacement as needed to continue pumping.

| 1. A type(low temperature) | |||||||||||||

| Plug Model | Casing | OD (mm) | ID (mm) | Steel grade | Plug OD (mm) | Plug ID (mm) | Plug length (mm) | Pressure (MPa) | Setting force (T) | Setting tool | WT (℃) | Salinity | Dissolving (1%) |

| HHAY257R-72-70-C2 | 4.5″ 4″ | 114.3 101.6 | Φ80- 90 | All | 72 | 28 | 210 | 70 | 44848 | Baker#10 | 20-50 | 0.5%-2% | 4 days |

| HHAY257R-88-70-C2 | 5.5″ 5″ 4.5″ | 139.7 127 114.3 | Φ96-104 | All | 88 | 30 | 255 | 70 | 44848 | Baker#10 | 20-50 | 0.5%-2% | 6 days |

| HHAY257R-98-70-C2 | 5.5″ 5″ | 139.7 127 | Φ104-116 | All | 98 | 40 | 270 | 70 | 44848 | Baker#20 | 20-50 | 0.5%-2% | 6 days |

| HHAY257R-108-70-C2 | 5.5″ | 139.7 | Φ115-127.5 | All | 108 | 48 | 310 | 70 | 44848 | Baker#20 | 20-50 | 0.5%-2% | 6 days |

| HHAY257R-112-70-C2 | 5.5″ | 139.7 | Φ121-130 | All | 112 | 50 | 318 | 70 | 44848 | Baker#20 | 20-50 | 0.5%-2% | 6 days |

| HHAY257R-140-70-C2 | 7″ | 177.8 | Φ150-155 | All | 140 | 55 | 340 | 70 | 44848 | Baker#20 | 20-50 | 0.5%-2% | 6 days |

| HHAY257R-145-70-C2 | 7″ | 177.8 | Φ155-160 | All | 145 | 60 | 345 | 70 | 44848 | Baker#20 | 20-50 | 0.5%-2% | 6 days |

| 2. B type(medium temperature) | |||||||||||||

| Plug model | Casing | OD (mm) | ID (mm) | Steel grade | Plug OD (mm) | Plug ID (mm) | Plug length (mm) | Pressure (MPa) | Setting force (T) | Setting tool | WT (℃) | Salinity | Dissolving (1%) |

| HHBY257R-72-70-L2 | 4.5″ 4″ | 114.3 101.6 | Φ80-90 | All | 72 | 28 | 210 | 70 | 44848 | Baker#10 | 50-80 | 0.5%-2% | 4 days |

| HHBY257R-88-70-L2 | 5.5″ 5″ 4.5″ | 139.7 127 114.3 | Φ96-104 | All | 88 | 30 | 255 | 70 | 44848 | Baker#10 | 50-80 | 0.5%-2% | 6 days |

| HHBY257R-98-70-L2 | 5.5″ 5″ | 139.7 127 | Φ104-116 | All | 98 | 40 | 270 | 70 | 44848 | Baker#20 | 50-80 | 0.5%-2% | 6 days |

| HHAY257R-108-70-L2 | 5.5″ | 139.7 | Φ115-127.5 | All | 108 | 48 | 310 | 70 | 44848 | Baker#20 | 50-80 | 0.5%-2% | 6 days |

| HHAY257R-112-70-L2 | 5.5″ | 139.7 | Φ121-130 | All | 112 | 50 | 318 | 70 | 44848 | Baker#20 | 50-80 | 0.5%-2% | 6 days |

| HHAY257R-140-70-L2 | 7″ | 177.8 | Φ150-155 | All | 140 | 55 | 340 | 70 | 44848 | Baker#20 | 50-80 | 0.5%-2% | 6 days |

| HHAY257R-145-70-L2 | 7″ | 177.8 | Φ155-160 | All | 145 | 60 | 345 | 70 | 44848 | Baker#20 | 50-80 | 0.5%-2% | 6 days |

| 3. C type(medium temperature) | |||||||||||||

| Plug model | Casing | OD (mm) | ID (mm) | Steel grade | Plug OD (mm) | Plug ID (mm) | Plug length (mm) | Pressure (MPa) | Setting force (T) | Setting tool | WT (℃) | Salinity | Dissolving (1%) |

| HHCY257R-72-70-M2 | 4.5″ 4″ | 114.3 101.6 | Φ80- 90 | All | 72 | 28 | 210 | 70 | 44848 | Baker#10 | 80-120 | 0.5%-2% | 4 days |

| HHCY257R-88-70-M2 | 5.5″ 5″ 4.5″ | 139.7 127 114.3 | Φ96-104 | All | 88 | 30 | 255 | 70 | 44848 | Baker#10 | 80-120 | 0.5%-2% | 6 days |

| HHCY257R-98-70-M2 | 5.5″ 5″ | 139.7 127 | Φ104-116 | All | 98 | 40 | 270 | 70 | 44848 | Baker#20 | 80-120 | 0.5%-2% | 6 days |

| HHCY257R-108-70-M2 | 5.5″ | 139.7 | Φ115-127.5 | All | 108 | 48 | 310 | 70 | 44848 | Baker#20 | 80-120 | 0.5%-2% | 6 days |

| HHCY257R-112-70-M2 | 5.5″ | 139.7 | Φ121-130 | All | 112 | 50 | 318 | 70 | 44848 | Baker#20 | 80-120 | 0.5%-2% | 6 days |

| HHCY257R-140-70-M2 | 7″ | 177.8 | Φ150-155 | All | 140 | 55 | 340 | 70 | 44848 | Baker#20 | 80-120 | 0.5%-2% | 6 days |

| HHCY257R-145-70-M2 | 7″ | 177.8 | Φ155-160 | All | 145 | 60 | 345 | 70 | 44848 | Baker#20 | 80-120 | 0.5%-2% | 6 days |

| 4. D type(high temperature) | |||||||||||||

| Plug model | Casing | OD (mm) | ID (mm) | Steel grade | Plug OD (mm) | Plug ID (mm) | Plug length (mm) | Pressure (MPa) | Setting force (T) | Setting tool | WT (℃) | Salinity | Dissolving (1%) |

| HHDY257R-72-70-H2 | 4.5″ 4″ | 114.3 101.6 | Φ80- 90 | All | 72 | 28 | 210 | 70 | 44848 | Baker#10 | 80-120 | 0.5%-2% | 4 days |

| HHDY257R-88-70-H2 | 5.5″ 5” 4.5″ | 139.7 127 114.3 | Φ96-104 | All | 88 | 30 | 255 | 70 | 44848 | Baker#10 | 120-160 | 0.5%-2% | 6 days |

| HHDY257R-98-70-H2 | 5.5″ 5″ | 139.7 127 | Φ104-116 | All | 98 | 40 | 270 | 70 | 44848 | Baker#20 | 120-160 | 0.5%-2% | 6 days |

| HHDY257R-108-70-H2 | 5.5″ | 139.7 | Φ115-127.5 | All | 108 | 48 | 310 | 70 | 44848 | Baker#20 | 120-160 | 0.5%-2% | 6 days |

| HHDY257R-112-70-H2 | 5.5″ | 139.7 | Φ121-130 | All | 112 | 50 | 318 | 70 | 44848 | Baker#20 | 120-160 | 0.5%-2% | 6 days |

| HHDY257R-140-70-H2 | 7″ | 177.8 | Φ150-155 | All | 140 | 55 | 340 | 70 | 44848 | Baker#20 | 120-160 | 0.5%-2% | 6 days |

| HHDY257R-145-70-H2 | 7″ | 177.8 | Φ155-160 | All | 145 | 60 | 345 | 70 | 44848 | Baker#20 | 120-160 | 0.5%-2% | 6 days |

| Max. test pressure | 600 to 900 bar / 60 to 90 MPa |

| Rated working pressure difference | 35/50/70 MPa |

| Max. working temperature | 50°C to 180°C |

| Setting tool | Baker #10 or #20 |

| Min. setting load | 100 KN |

| Max. setting load | 160 KN |

| Max. drop load | 140 KN |

| Water-soluble medium | 0.5 to 3% chloride ion liquid |

| Sealing stability period | 24 hours |

| Loss of sealing time | 2 to 3 days |

| Completely water soluble time | 6 to 10 days |

| Setting and feeding method | Cable or hydraulic feeding |

| Applicable wellbore conditions | Vertical wells and horizontal wells without direct contact with acidic operating environment |

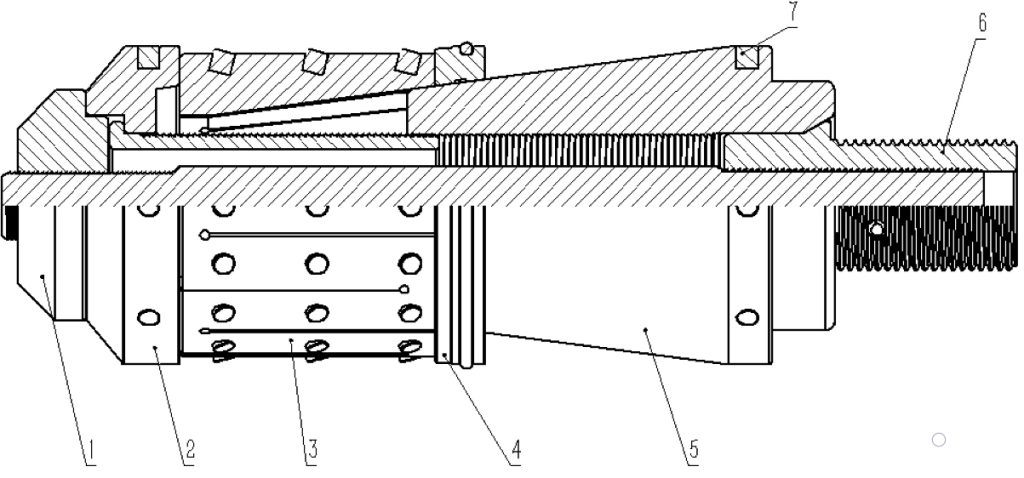

1-Releasing Ring 2-Lower Tray 3-Expansion Slip

4-Sealing Ring 5-Upper Cone 6-Connection Nuts

7-Ceramic Bite Button

———— Plug Pumping Down Process ————————————————— Status Before Dropping Ball ————————————————— Status After Dropping Ball ————

* The vertebral body on frac plug contains an inner cone surface. During ball dropping operations, the dissolvable ball can form a good sealing state with the inner cone surface, thereby blocking the inner hole and preventing further downward flow of fracturing fluid.

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————