Overview

Well control equipment refers to a set of specialized tools and systems used in the oil and gas industry to manage and control the pressure within a well during drilling, completion, and production operations. The importance of well control equipment cannot be overstated. It helps ensure the safety of personnel and the integrity of the well and the surrounding environment. For example, in the event of a sudden pressure increase or a kick, the proper functioning of BOPs can prevent a potentially catastrophic blowout. Additionally, effective well control equipment allows for smooth and safe drilling and production operations, minimizing disruptions and risks.

Feature

- Safety Features: Include redundant systems and fail-safes to enhance overall safety.

- High Reliability: It must be able to function accurately and dependably in critical situations to prevent disasters.

- Quick Response: Able to act rapidly to control well pressure changes. Like a choke manifold that can adjust the fluid flow quickly.

- Robust Construction: Built to withstand harsh conditions such as high pressure, temperature variations, and corrosive substances.

- Easy to Operate: With user-friendly interfaces and controls for efficient handling by the crew. BOP control panel that is intuitive and simple to use.

- Versatility: Capable of adapting to different well types and operating scenarios. It can be adjusted or configured differently depending on the specific well requirements.

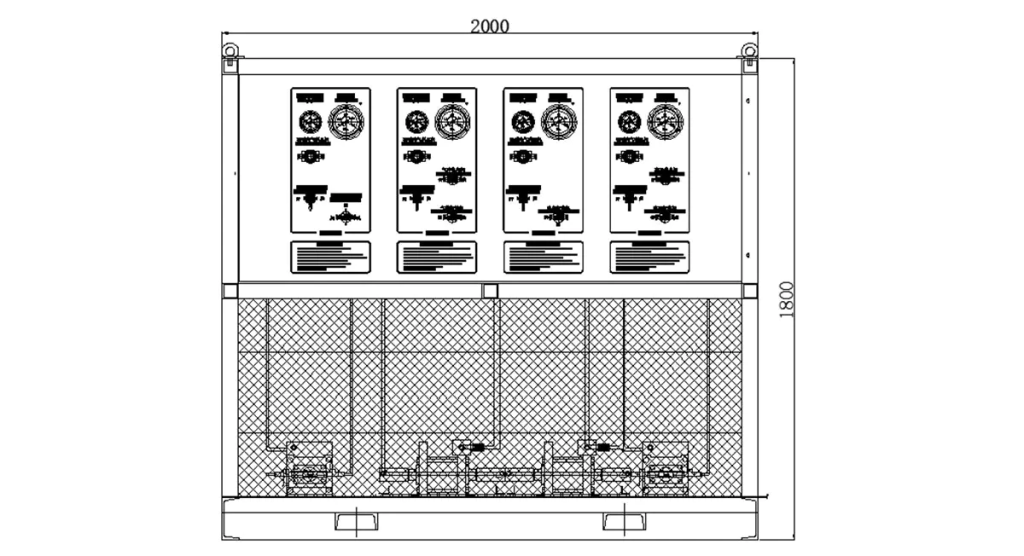

- Accurate Monitoring Capabilities: Incorporate sensors and gauges to provide real-time data on well conditions. Such as pressure gauges that give precise pressure readings.