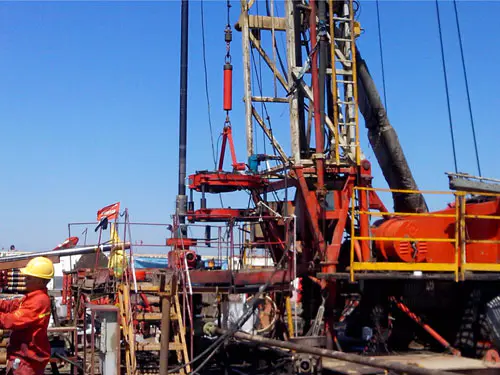

Tubing and Casing Thread Gas-tight Sealing Testing services

Tubing gas seal test. , casing gas seal test,

coupling gas seal test, thread air seal test, helium gas seal test,

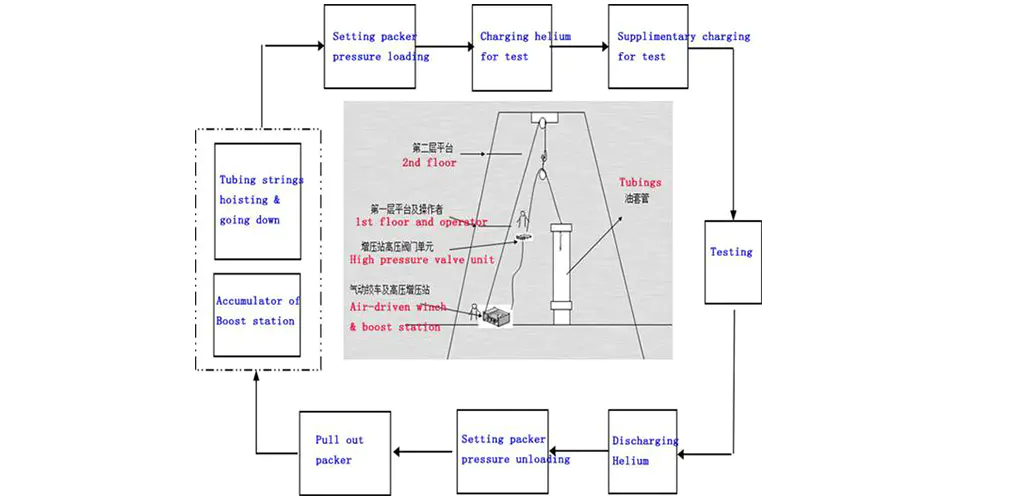

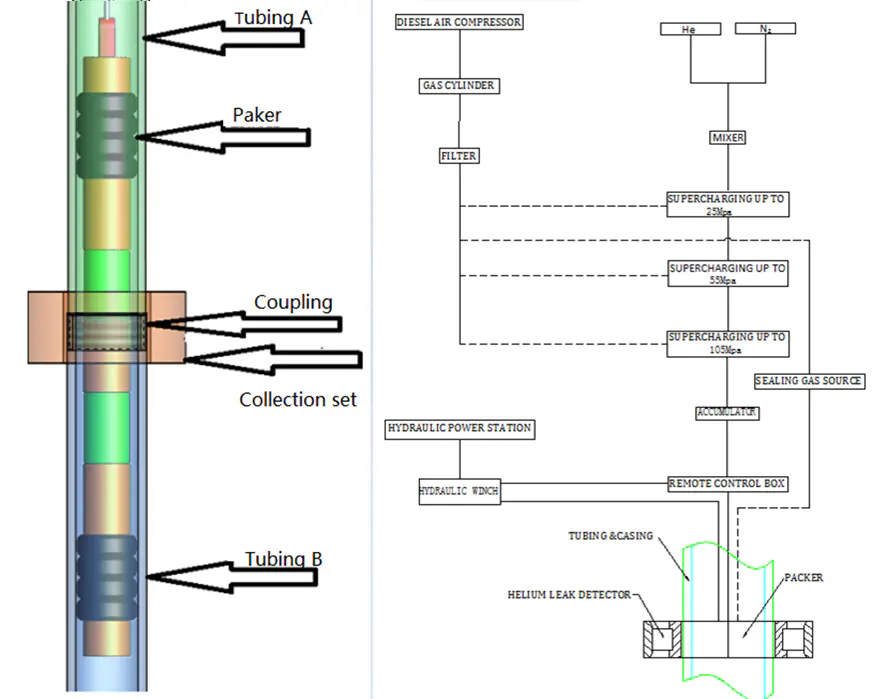

Use helium (or a mixture of helium and nitrogen) to check the thread tightness of the oil and casing joints.

Detection principle:

Use a winch to lower the special packer to the joint of the oil and casing, and then pass the high-pressure helium gas of 35-105Mpa, and detect the helium molecules through the detection instrument outside the coupling. If the helium molecule is detected, the coupling is detected. The sealing performance is defective; if the helium molecules are not detected, the coupling sealing performance is good.

| Medium (He) | The molecular weight of helium (He) in nature is only larger than that of hydrogen (H2), but its chemical and physical properties are more stable than hydrogen, and the content of helium (He) molecules is very low in the natural atmosphere. So by pressing the helium, you can detect very small leaks. |

| Pressure (105mPA) | Oil and casing need to withstand the pressure of the formation in the production well. Using the method of simulating downhole pressure, high pressure is generated to detect the sealing performance of the coupling. |

| Volume (3L) | Gas has a strong compression capacity, in order to improve work efficiency and cost, the packer is used to seal the coupling position. |

| The winch | Uses a winch to quickly lift the packer to the coupling position. |

Equipment Composition and Technical Parameters

① Air power unit

● Output air pressure: 10bar

● Output air flow: 10 square meters/minute

② Booster unit

● Output pressure: 1050bar

● Output flow: 300L/min

● Lifting weight: 5T

③ Compounding instrument

● Helium and nitrogen were mixed at a ratio of 1:9.

④ Collection

● Detection accuracy can reach: 1×10-7 mbarL/min

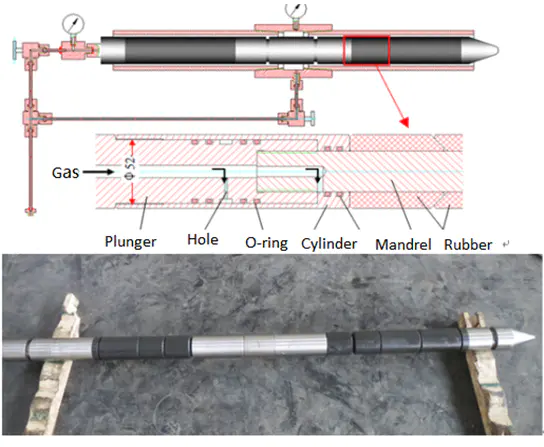

⑤ Packer

Pressure: 1050bar

Fatigue life: 300 times

Specifications: 5- 7 inch

Features

Safety

The exploration gas in the detection is inert gas, the carrier gas nitrogen is not a gas, the helium gas is lighter than air, safe to use, helium gas nitrogen is non-corrosive, no damage to the human body and the detection object ;

Reliability

Due to the small diameter of the helium molecules, easy to penetrate in the gas seal buckle;

Sensitivity

The helium leak detector has high sensitivity and can detect helium gas with a leak rate of 1×10-7 bar·ml/sec, that is, it can be detected as long as helium leaks;

Construction is fast

The detection speed is fast, and the average single root detection speed is 2:00 minutes, which has little impact on the completion process.