The Science and Impact of Dissolvable Frac Plug Materials in Oilfields

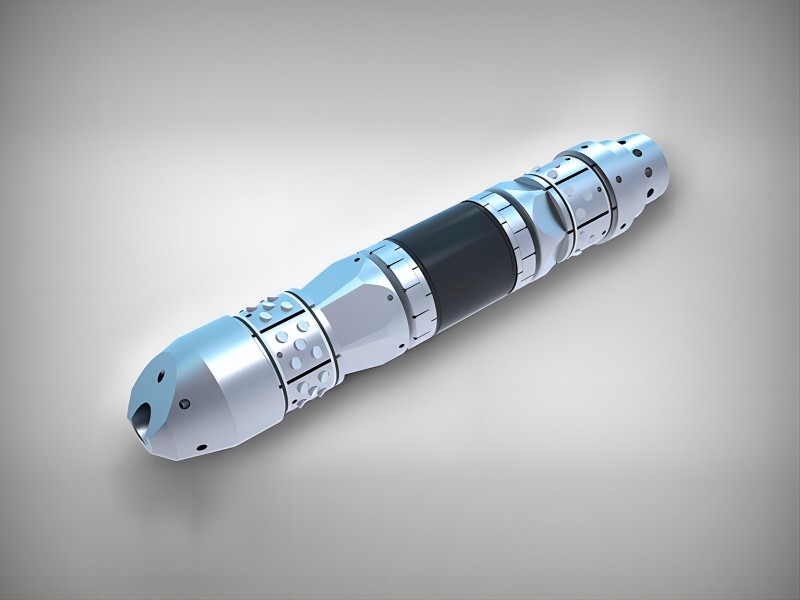

Dissolvable frac plug materials represent a significant innovation in the oil and gas industry, particularly in staged fracturing operations. These materials are designed to dissolve under specific downhole conditions, eliminating the need for post-fracturing milling and enhancing operational efficiency. By saving time and reducing costs, they simplify processes and minimize operational complexity. This article explores the different types of dissolvable frac plug materials, their mechanisms, and the technical, economic, and environmental impacts of their application in oilfields.

Types of Dissolvable Fracturing Plug Materials

Dissolvable fracturing plug materials are engineered for specific environmental conditions encountered in oilfields. Key materials include magnesium-based alloys, hydrogenated nitrile butadiene rubber (HNBR), polyglycolic acid (PGA), and cellulose fibers. Each material offers unique characteristics, dissolution mechanisms, and advantages for various applications.

1. Dissolvable Magnesium Alloys

Composition and Characteristics

Dissolvable Magnesium alloys are composed of pure magnesium combined with other metal elements such as aluminum, zinc, and rare earth elements. These dissolvable alloys are known for their high strength, stiffness, and excellent machinability. One of their key advantages is the ability to customize their degradation rates through various methods, including composition design, heat treatment, plastic deformation, and surface treatments.

Magnesium’s reactive nature makes it susceptible to oxidation in atmospheric environments and corrosion in acidic or saline conditions. These properties make dissolvable magnesium alloys ideal for applications where controlled degradation is necessary, such as in dissolvable frac plugs.

Dissolution Mechanism

The dissolution of magnesium-based alloys is governed by electrochemical corrosion. In the acidic or saline environments typically found in oilfields, magnesium undergoes oxidation:

Mg→Mg2++2e−

Simultaneously, electrons released during this reaction are consumed in the reduction of hydrogen ions or other oxidizing agents:

2H++2e−→H2

The dissolution rate can be influenced by the alloy composition and treatment processes, ensuring compatibility with varying well conditions.

2. Hydrogenated Nitrile Butadiene Rubber (HNBR)

Composition and Characteristics

Hydrogenated nitrile butadiene rubber (HNBR) is a high-performance synthetic rubber known for its exceptional resistance to oil, heat, and mechanical stress. The hydrogenation process enhances its saturation level, improving its thermal and oxidative stability. These properties make HNBR suitable for harsh subsurface conditions encountered during fracturing operations.

Dissolution Mechanism

HNBR undergoes chemical degradation in acidic environments. Acidic substances attack the rubber’s molecular chains, causing them to break down gradually. The dissolution process can be controlled by adjusting the acid concentration and reaction temperature, ensuring that the material degrades at the desired rate to match operational needs.

3. Polyglycolic Acid (PGA)

Composition and Characteristics

Polyglycolic acid (PGA) is a biodegradable polymer with excellent mechanical properties and a controllable degradation rate. As an environmentally friendly material, its degradation products are non-toxic, making it suitable for applications in regions with strict environmental regulations.

Dissolution Mechanism

PGA degrades through hydrolysis in aqueous environments. Water molecules cleave the polymer chains, gradually breaking the material down into small, non-toxic molecules. The degradation rate of PGA can be adjusted by altering its molecular weight or crystallinity, allowing it to be tailored to specific well conditions.

4. Cellulose Fibers

Composition and Characteristics

Cellulose fibers are natural polymers derived from plant sources. They are biocompatible and have adjustable degradation rates, which can be enhanced through chemical or physical modification. These fibers exhibit good mechanical properties and resistance to chemical corrosion, making them viable for downhole applications.

Dissolution Mechanism

Cellulose fibers degrade biologically through the action of enzymes or microorganisms. In addition, chemical hydrolysis can occur under acidic or alkaline conditions, breaking the cellulose into smaller molecules. These dual pathways ensure that cellulose fibers can effectively degrade in various subsurface environments.

Impact of Dissolvable Frac Plugs on Oilfield Operations

The adoption of dissolvable frac plugs has brought significant changes to oilfield operations, affecting technical efficiency, economic outcomes, and environmental sustainability.

1. Technical Impact

1.1. Enhanced Operational Efficiency

One of the most significant advantages of dissolvable fracturing plugs is their ability to streamline operations. Traditional plugs require post-fracturing milling, which is time-consuming, complex, and risky. Dissolvable plugs eliminate this step, significantly improving efficiency. For instance, studies have shown that using these plugs can reduce the testing cycle of a single well by up to 30%, accelerating overall project timelines.

1.2. Restoration of Full Bore Diameter

Dissolvable plugs dissolve completely after completing their function, restoring the wellbore’s full diameter. This simplifies subsequent operations, such as re-completions or perforations, and facilitates unobstructed oil and gas flow. In contrast, traditional plugs often leave debris that can hinder further operations, impacting productivity.

1.3. Uncertainty in Fracturing Effectiveness

Despite their advantages, dissolvable plugs face challenges related to their dissolution rates. Factors such as temperature, pressure, and mineral content of the well can affect the dissolution process, potentially causing incomplete breakdown or extended dissolution times. This uncertainty may impact fracturing outcomes and, in some cases, lead to partial blockages in the wellbore.

2. Economic Impact

2.1. Cost Reduction

By eliminating the need for milling, dissolvable plugs significantly reduce operational costs. Shorter operation times translate into lower labor and equipment costs. Estimates suggest that using these plugs can lower total costs by approximately 20%, making oilfield development more economical.

2.2. Higher Return on Investment

The efficiency gains and cost savings from dissolvable plugs contribute to improved project profitability. The increased operational efficiency allows for faster resource recovery and reinvestment in other projects, creating a positive feedback loop for oilfield development.

3. Environmental Impact

3.1. Reduced Pollution

Dissolvable plugs often use environmentally friendly materials such as PGA and magnesium-based alloys. These materials degrade into harmless byproducts, aligning with the industry’s shift toward sustainable practices. For instance, PGA’s non-toxic degradation products make it ideal for operations in areas with strict environmental regulations.

3.2. Potential Risks to Groundwater Quality

While generally considered eco-friendly, dissolvable materials can pose risks if their byproducts are not adequately managed. For example, some materials may release harmful substances under specific conditions, potentially contaminating groundwater or soil. This underscores the need for rigorous material selection and environmental monitoring.

4. Long-Term Production Impacts

4.1. Sustained Production Levels

By improving wellbore conditions and enabling efficient fracturing, dissolvable plugs support sustained production levels. The restoration of full bore diameter reduces flow resistance, enhancing long-term production efficiency.

4.2. Residual Effects of Dissolution Byproducts

Incomplete dissolution or accumulation of byproducts can lead to sedimentation, affecting wellbore integrity and flow efficiency. These challenges necessitate careful material selection and operational planning to minimize potential long-term impacts.

Wrap Up

Dissolvable frac plug materials represent a significant advancement in oilfield technology, offering solutions that enhance efficiency, reduce costs, and minimize environmental impact. Their diverse material types—from dissolvable magnesium alloys to biodegradable polymers—allow for tailored applications in various operational conditions. However, challenges such as dissolution uncertainties and environmental risks require ongoing research and innovation.

As the industry continues to prioritize sustainability and efficiency, dissolvable plug materials are poised to play a pivotal role in the future of oil and gas extraction, driving progress toward safer, greener, and more cost-effective operations.