The principle of gas booster pump and troubleshooting if it does not work

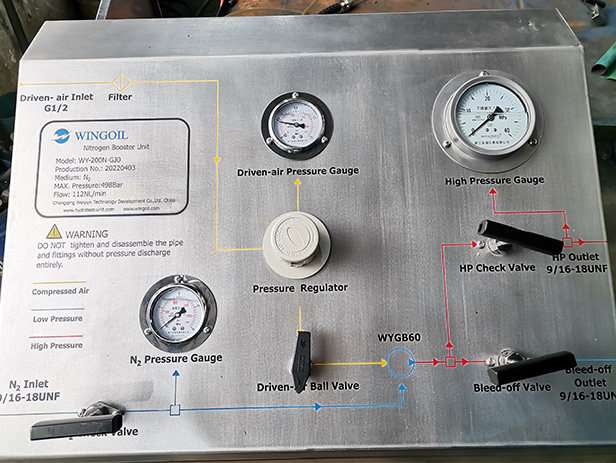

The gas booster pump, also known as the air booster pump, is driven by low-pressure gas at the piston end with a large area and generates high-pressure fluid at the piston end with a small area. It can be used to compress air and other gases, and the driving air pressure allows for stepless output air pressure adjustment. When the initial air pressure system needs to be increased, it is employed in the workplace. It can be used to boost pressure, calibrate safety valves, test valves, and wellhead equipment with water bubbling, and pressurize air and other gases.

The air booster pump plays a pivotal role in the daily production of the industry, so what is its principle? What is the reason for the failure to work and how to deal with it properly?

Air booster pump working principle

The air booster pump operates on the premise of using compressed air as a power source to create high-pressure gas with a small piston area in response to the low-pressure push of a big piston area. The piston areas are compared in the boost ratio, which establishes the output pressure.

The gas booster pump can enhance the operating system’s air pressure multiple times and is appropriate for environments where the original air pressure system has to be pressurized. High-purity gas cannot be supercharged with this pump. The factory gas circuit’s output pressure, which is typically no higher than 10MPa, is equal to the supercharging ratio times the intake pressure.

Consequently, a gas booster pump can be used to supply a limited quantity of local high-pressure gas in the following situations. High pressure is necessary for some gas circuit devices or for some people. The booster pump provides high-pressure gas to maintain the pneumatic device’s regular operation when the pressure of the factory’s primary air circuit lowers and the working pressure of the pneumatic machine cannot be assured. However, the output force needs to be ensured because large-diameter cylinders cannot be set.

The reason and solution for the booster pump not working

The reversing valve may be unclean or the seal may be damaged, which prevents the hot water booster pump from operating normally. These are some of the causes of the air booster pump not working. The two pistons’ joint is destroyed, the cotter pin is lost, and the two piston rods are out of alignment, which prevents the piston rod from moving correctly. At the seal, there is an air leak. Air leaks on the top and lower sides of the piston are the results of wear and driving that damages the piston sealing ring.

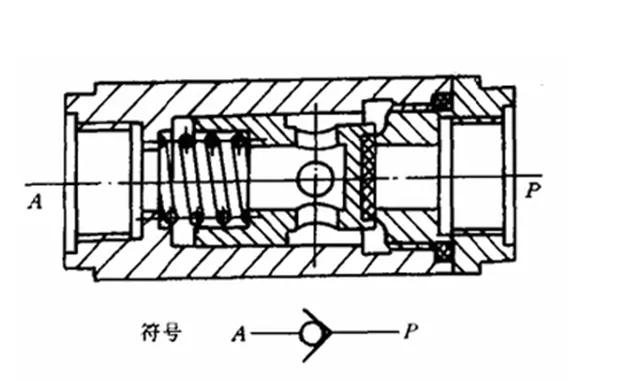

1. The one-way valve leaks

The one-way valve’s purpose is to prevent the backflow of pressurized water, which causes the pressure to drop. Leakage is a problem with the one-way valve’s ability to seal. Failure to reach the set value will also cause the circulating booster pump to fail to work.

Solution: To see if the pointer will lower, turn off the power to the air booster pump after setting it to the desired value and marking it. A water leak is present if it falls. If there is no pressure gauge, you can turn on the faucet to check if the water pressure has drastically decreased after turning off the system for a while.

2. The shutdown pressure is too high

A high shutdown pressure will prevent the pipeline booster pump from operating at the desired level. Verify the relevant pressure value a second time.

Solution: If a pointer pressure gauge is present, you can create a mark after checking the pointer pressure value without stopping the machine. Recheck the shutdown pressure value and make the necessary adjustments to the established pressure value.

3. The outlet pressure of the booster pump is low

The booster pump has a very high working frequency, but the pressure cannot be increased, and the noise it makes is also very loud. Long-term use of this mode of operation can easily harm the pump. Likewise, a booster pump will operate more frequently and be more susceptible to damage if the output pressure of the pump is relatively low.

There have been instances of the cascaded booster pump operating in such unique circumstances: the pressure relief valve continually releases pressure; the booster pump’s frequency is high; and the booster pump’s frequency is low. It is discovered after careful examination that the set value is inadequate. The adjustable pressure switch valve significantly deflates after increasing the specified value. The booster pump’s malfunction was subsequently verified. It came out that the pipeline was still linked to the upper side of the booster pump’s control valve, which had previously been thought to be detached.

As a result, the booster pump continues to boost continuously. In other words, the pump is identical to the model needed by the design drawings but operates abnormally because a minor component and an air channel plug are missing. This component ought to fit inside the pump so that it is difficult to see.

Solution: To reduce the booster pump’s working frequency and keep the pump unit functioning normally, turn off the air intake of the cut-off ball valve of the booster pump. Installing the plug is the final step in the process.

4. The piston stops working

The booster pump abruptly stopped functioning, preventing an increase in total pressure. Upon closer examination, it was discovered that its reversing valve was immobile. As a result, I shut off the booster pump group’s compressed air, and when I unloaded it, I discovered that a blast of air had ejected the valve core. It turns out that the valve core is immobile since there is no pressure release and there is the pressure at the right end of the valve. Because the piston stops in the middle of its travel and does not contact the control valve, there is no pressure relief.

Solution: Replace the reversing valve V3 and restart the pump unit after turning on the compressed air. Another method for resolving this issue is to stop using compressed air, wait for the high-pressure gas outlet pressure to drop to around 3 Mpa, and then restart the pump unit.