Pressure Testing Pumps and Hydrostatic Testing: Tips for Safety and Integrity

Pressure testing pumps are essential tools for ensuring the safety and integrity of pressure vessels and pipe systems. By applying pressure to these systems, pressure testing pumps can detect any leaks or weak spots that could pose a safety hazard. Hydrostatic testing is a type of pressure testing that uses water as the pressurizing fluid. It is the most common type of pressure testing because water is a non-compressible fluid and is therefore very reliable.

What is a Pressure Testing Pump?

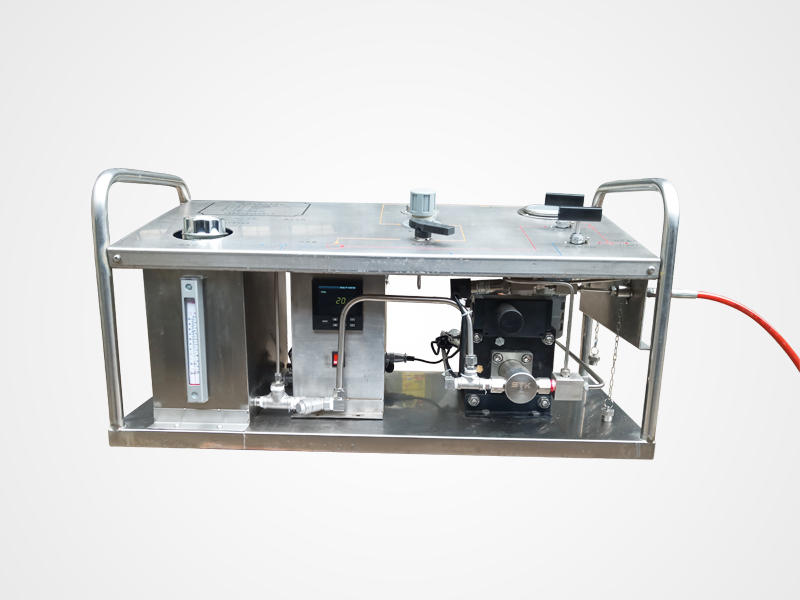

A pressure testing pump is a device that is used to apply pressure to a pressure vessel or pipe system. It is typically a positive displacement pump, which means that it displaces a fixed volume of fluid with each stroke. This allows the pump to build up pressure in the system gradually.

There are three main types of pressure testing pumps:

- Manual pressure testing pumps are operated by hand. They are typically the simplest and least expensive type of pressure testing pump.

- Electric pressure testing pumps are powered by an electric motor. They are more powerful than manual pressure testing pumps and can be used to test larger systems.

- Hydraulic pressure testing pumps are powered by a hydraulic system. They are the most powerful type of pressure testing pump and can be used to test very large systems.

What is Hydrostatic Testing?

Hydrostatic testing is a type of pressure testing that uses water as the pressurizing fluid. It is the most common type of pressure testing because water is a non-compressible fluid and is therefore very reliable.

Hydrostatic testing is typically performed in two steps:

- The pressure vessel or pipe system is filled with water.

- The pressure is gradually increased until it reaches the desired level.

The pressure is then maintained for a specified amount of time, typically 15 minutes. This allows any leaks or weak spots in the system to be detected.

Why is Hydrostatic Testing Important?

Hydrostatic testing is important because it can help to prevent accidents and injuries. If a pressure vessel or pipe system leaks, it can release dangerous fluids or gases. It can also cause structural damage to the system.

Hydrostatic testing is also required by many regulations. For example, the American Society of Mechanical Engineers (ASME) has published standards for hydrostatic testing. The Occupational Safety and Health Administration (OSHA) also has regulations governing the use of pressure testing pumps.

How to Use a Pressure Testing Pump?

To use a pressure testing pump, you will need to follow these steps:

- Connecting the pump to the pressure vessel or pipe system: The pump must be connected to the pressure vessel or pipe system in a way that ensures that the pressure is evenly distributed throughout the system. This is typically done by using a pressure gauge to monitor the pressure and adjusting the pump as needed.

- Filling the pressure vessel or pipe system with water: The pressure vessel or pipe system must be filled with water before the pressure can be increased. This is done to ensure that there are no air pockets in the system, which could cause the pressure to be uneven.

- Pressurizing the system to the desired PSI: The pressure is gradually increased until it reaches the desired level. The desired level of pressure is typically specified by the manufacturer of the pressure vessel or pipe system.

- Maintaining the pressure for the specified amount of time: The pressure is then maintained for a specified amount of time. This allows any leaks or weak spots in the system to be detected. The amount of time that the pressure is maintained is typically specified by the manufacturer of the pressure vessel or pipe system.

- Releasing the pressure and disconnecting the pump: Once the specified amount of time has elapsed, the pressure is released and the pump is disconnected from the pressure vessel or pipe system.

Safety Precautions

It is important to follow all safety precautions when using a pressure testing pump. These precautions include:

- Always wear safety glasses and gloves when using a pressure testing pump. This will protect you from flying debris and sharp objects.

- Do not exceed the rated pressure of the pressure vessel or pipe system. This could cause the system to rupture, resulting in serious injury or death.

- Inspect the pump for leaks before each use. If the pump is leaking, it could cause the pressure vessel or pipe system to fail.

- Never leave a pressurized system unattended. If the pressure in the system drops, it could cause the system to fail.

- Release the pressure slowly to avoid damage to the system. Releasing the pressure too quickly could cause the system to rupture.

Conclusion

Pressure testing pumps are an essential tool for ensuring the safety and integrity of pressure vessels and pipe systems. There are a variety of pressure testing pumps available, each with its own advantages and disadvantages. It is important to use the correct type of pressure testing pump for the job and to follow all safety precautions.