Optimizing Pneumatic Systems with the Air Control Unloading Valve

Pneumatic systems rely on precise air pressure control to operate efficiently and safely. One crucial component that plays a vital role in maintaining optimal air pressure is the air control unloading valve. This article explores the significance of this valve in pneumatic systems, its integration with air control mechanisms, and the benefits it offers.

Pressure Generation in Pneumatic Systems

To understand the role of the air control unloading valve, it is essential to grasp the process of pressure generation in pneumatic systems. Pressure generators such as compressors and pumps are responsible for creating the necessary air pressure. These devices ensure a continuous supply of compressed air, which powers various pneumatic components.

Air Control Unloading Valve: Definition and Function

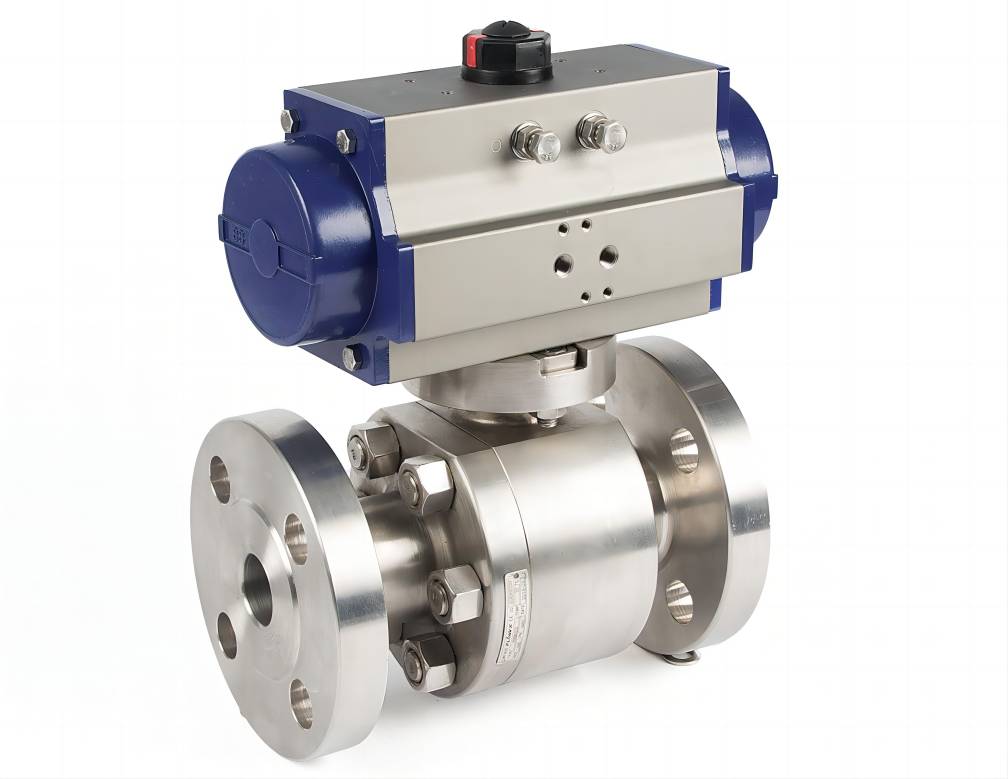

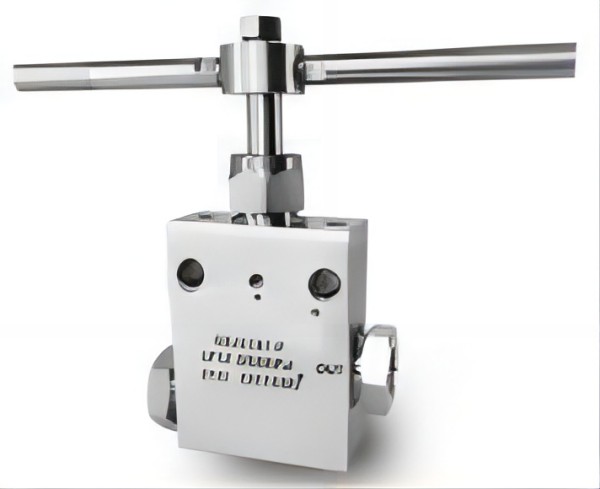

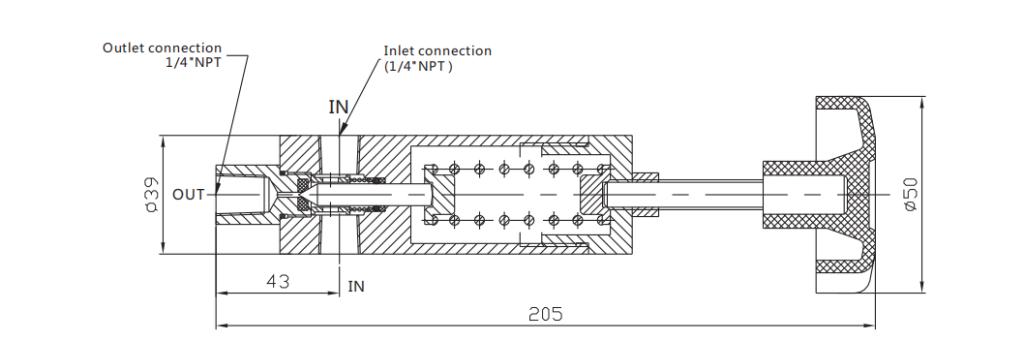

The air control unloading valve is a crucial component designed to regulate air pressure within pneumatic systems. It is typically installed at a strategic location within the system, where it monitors and controls the pressure level. This valve ensures that the pressure does not exceed safe limits, preventing potential damage to system components and ensuring operational safety.

Key Features and Working Principles of Air Control Unloading Valve

The air control unloading valve comprises several key features that contribute to its effectiveness. It consists of a pressure sensor, a control mechanism, and an exhaust port. The pressure sensor continuously monitors the air pressure within the system. When the pressure surpasses a predetermined threshold, the control mechanism activates, opening the exhaust port. This allows excess air to escape, effectively unloading the system and maintaining stable pressure.

Significance of the Air Control Unloading Valve

- Prevention of System Overpressure and Damage

By actively monitoring and regulating air pressure, the air control unloading valve prevents system overpressure. Excessive pressure can lead to equipment failure, leaks, or even catastrophic accidents. The valve acts as a safety mechanism, safeguarding the system and its components.

- Controlled Air Release and System Stability

The valve ensures controlled air release, preventing abrupt pressure drops that can negatively impact system performance. By maintaining a stable pressure, it promotes smooth operation and minimizes the risk of sudden system failures.

- Energy Consumption and Cost Efficiency

Efficient air control is essential for reducing energy consumption in pneumatic systems. The air control unloading valve optimizes energy usage by releasing excess air only when required. This leads to cost savings and promotes sustainability.

- Enhanced System Performance and Longevity

The valve contributes to overall system performance and longevity. Preventing excessive pressure, it reduces wear and tear on system components, prolonging their lifespan. This leads to improved reliability and reduced maintenance costs.

Integration of Air Control Unloading Valve in Air Control Systems

Effective air control mechanisms are vital for optimal system performance. The air control unloading valve works in synergy with other air control components, such as regulators and flow control valves. It complements these mechanisms by providing an additional layer of pressure control, ensuring precise and reliable operation.

Conclusion

The air control unloading valve is a crucial component in pneumatic systems, playing a pivotal role in maintaining optimal air pressure. By preventing overpressure, ensuring controlled air release, and optimizing energy consumption, this valve enhances system performance and prolongs equipment life. Its integration with air control mechanisms further enhances system efficiency. As technology continues to advance, we can expect further developments in air control technology, leading to even more efficient and reliable pneumatic systems in the future.