Nitrogen Generator Container Unit

- Model: WY-210N-TJ0-KFD49-5

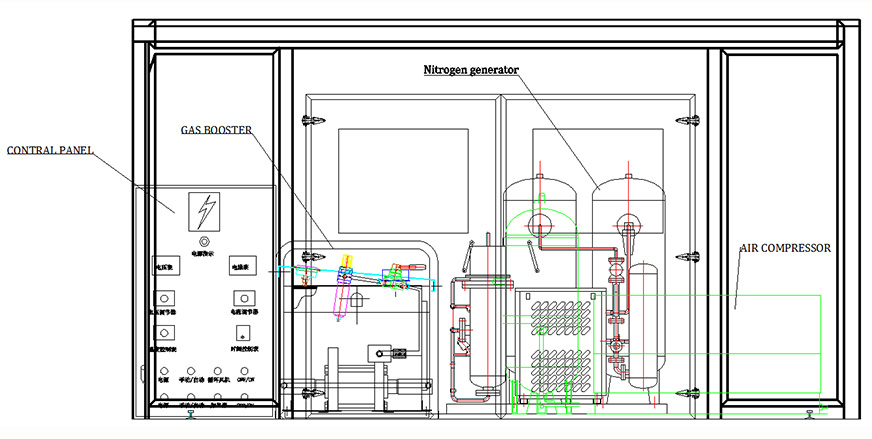

- The unit is housed in a durable, weather-resistant container that can be easily transported and installed on-site. The container unit is fully equipped with all necessary components, including the nitrogen generator, air compressor, and filtration system, ensuring a seamless and uninterrupted operation.

Share to

Overview

The nitrogen generator container unit is a device that integrates an air compressor, a nitrogen generator, and a nitrogen booster into a standard container, and is used to realize the full function from nitrogen generation to nitrogen pressure boosting. Due to its structural superiority, it is especially suitable for field nitrogen production operations that are frequently transported.

Feature

- The purity of nitrogen can reach 99.99%.

- Infinitely variable output pressure and flow rate.

- Mobile container unit for easy transportation and lifting.

- Holds static pressure without generating heat or consuming power.

- When the set pressure is reached, the equipment automatically stops and is safe to use.

- Integrates air compressor, nitrogen generator, and nitrogen booster, compact structure and easy operation.

Model: WY-210N-TJ0-KFD49-5

Model: WY-210N-TJ0-KFD49-5

Air Compressor

| Model | QGF-30/8 |

| Power supply | 380V / 3 phase / 50Hz |

| Power | 30KW |

| Displacement | 4.5 m³/min |

| Outlet pressure | 8 bar / 116 psi |

Nitrogen Generator

| Power supply | 220V/50Hz |

| Power | 0.5 KW |

| Air source | 7 to 10 bar |

| Nitrogen flow rate | ≥5 NM3/h (20°C, 101.325KPa) |

| Nitrogen purity | 99.9 % to 99.9999% |

| Nitrogen pressure | ≤ 5bar (adjustable) |

| Ambient temperature | 0 to 45°C |

| Air gas tank | Volume of 0.3m³, pressure level of 10bar, safety valve setting pressure of 10.5bar |

| Nitrogen gas tank | Volume of 0.3m³, pressure level of 10bar, safety valve setting pressure of 8.4bar |

Gas Booster

| Design pressure | 210 bar / 21 MPa |

| Pipe pressure | 420 bar / 42 MPa |

| Ball valve pressure | 420 bar / 42 MPa |

| Primary gas tank | Volume 1.6 L, pressure class 315 bar |

| Secondary gas tank | Volume 10 L, pressure class 315 bar |

| Safety valve | Set pressure 220 bar |

| Ambient temperature | 0 to 45°C |

Connection

| Compressed air inlet | 1/2FNPT |

| High pressure outlet | G1/4M-60° |

| Inlet | DN15 |

| Sewage outlet | 1/2FNPT |

| High pressure hose interface | G1/4F-60° |

Structure

| Panel | Stainless Steel |

| Gas cylinder | Carbon steel |

| Pressure gauge | Stainless Steel |

| Valve | Stainless Steel |

| Tube | Stainless Steel |

| Connections | Stainless Steel |

| Hydraulic Cylinder | Anodized aluminum |

| Piston | Stainless Steel |

| Booster pump head | Stainless Steel |

| Cabin | Carbon steel |

Hydraulic Pressure Static Conditions (@7bar)

| Air Pressure (bar) | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Hydraulic Pressure (bar) | 0 | 54 | 100 | 148 | 195 | 240 | 289 | 336 |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————