Hydrostatic Test Pumps: Ensuring the Integrity of Pressurized Systems

Hydrostatic testing plays a vital role in guaranteeing the safety and reliability of pressurized systems across various industries. This process involves pressurizing a system with a liquid, typically water, to a specific level exceeding its normal operating pressure. By identifying and addressing any leaks or weaknesses before regular operation, hydrostatic testing helps prevent catastrophic failures and potential injuries. A crucial tool for conducting hydrostatic testing is the hydrostatic test pump.

What is a Hydrostatic Test Pump?

A hydrostatic test pump is a specialized pump designed to generate high-pressure liquid flow for pressurizing a system under test. These pumps come in various configurations to suit different pressure requirements and application scenarios. They can be manually operated, electric-powered, pneumatic (air-powered), or even drill-powered. Regardless of the power source, the core function of a hydrostatic test pump remains the same: creating high-pressure liquid to pressurize a system for leak detection and integrity evaluation.

Types of Hydrostatic Test Pumps

There are four primary categories of hydrostatic test pumps, each with its own advantages and applications:

- Manual Hydrostatic Test Pumps: These are the most basic and affordable type of hydrostatic test pump. They are typically hand-operated using a lever or handle and are suitable for generating moderate pressure levels (up to 3000 PSI) for smaller systems. While they require physical exertion, manual pumps are lightweight, portable, and ideal for field applications where access to electricity or compressed air may be limited.

- Electric Hydrostatic Test Pumps: Electric hydrostatic test pumps offer a more convenient and less physically demanding alternative to manual pumps. They are powered by an electric motor and can generate higher pressure outputs (up to 10,000 PSI) compared to manual pumps. Electric pumps are suitable for various applications, including testing plumbing systems, boilers, pressure vessels, and fire sprinkler systems.

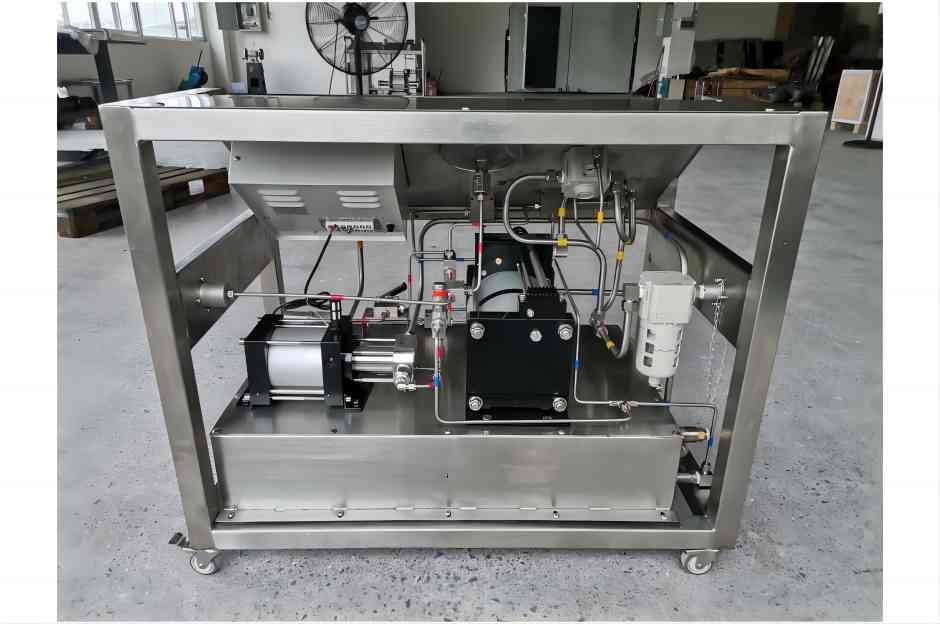

- Pneumatic Hydrostatic Test Pumps: These pumps utilize compressed air to drive a hydraulic piston, generating high-pressure liquid. Pneumatic pumps are often favored for their portability and ability to generate very high pressures (up to 30,000 PSI) for testing heavy-duty industrial equipment and pipelines.

- Drill-Powered Hydrostatic Test Pumps: These are a unique category of hydrostatic test pumps designed to leverage the power of a cordless drill (not included) for operation. They are lightweight and highly portable, making them ideal for field use. Drill-powered pumps typically generate moderate pressure levels (up to 5000 PSI) and are suitable for testing smaller pressurized systems.

How Hydrostatic Test Pumps Work?

Hydrostatic test pumps function by converting mechanical energy into high-pressure liquid flow. Here’s a step-by-step breakdown of the working mechanism:

- Liquid Intake: The pump is equipped with a reservoir that holds the testing liquid. This liquid is typically clean water; however, for specific applications, a designated testing fluid might be required (check the manufacturer’s instructions and relevant regulations).

- Power Source: Depending on the pump type, the power source can vary.

- Manual Pumps: These pumps utilize a lever or handle that the operator moves back and forth to create suction.

- Electric Pumps: An electric motor provides the power for these pumps. The motor is connected to the pump’s internal mechanism via a shaft or gears.

- Pneumatic Pumps: Compressed air drives a piston within the pump, generating the necessary force.

- Drill-Powered Pumps: These pumps leverage the power of a cordless drill (not typically included) to operate the internal mechanism.

- Generating Pressure: The chosen power source drives the pump’s internal mechanism. This mechanism typically involves a piston or diaphragm that moves within a cylinder. As the piston or diaphragm moves, it creates a low-pressure zone within the pump chamber.

- Liquid Intake with Check Valve: Due to the low pressure created in the pump chamber, liquid from the reservoir flows into the chamber through a one-way check valve. This check valve ensures that the liquid only flows in one direction, preventing it from flowing back into the reservoir during the pressurization process.

- Pressure Build-up: With the continued operation of the power source, the piston or diaphragm continues to move within the cylinder, reducing the volume of the chamber. This decrease in volume increases the pressure of the trapped liquid within the chamber.

- Pressure Relief Valve (Safety Feature): A pressure relief valve is a crucial safety feature built into the pump. This valve is calibrated to a specific pressure limit. If the pressure within the pump chamber exceeds this limit due to malfunction or operator error, the pressure relief valve automatically opens, releasing excess pressure and safeguarding the pump from damage.

- High-Pressure Output: The high-pressure liquid generated within the pump chamber is channeled out of the pump through an outlet port. This port is typically equipped with a connector for attaching high-pressure hoses.

- Pressure Monitoring: A pressure gauge connected to the pump displays the real-time pressure level of the liquid exiting the outlet port. The operator can monitor this gauge and adjust the pump’s operation (if applicable) to maintain the desired pressure level for the test.

- Directing Flow to the System: The high-pressure liquid is directed from the pump’s outlet port towards the system under test via hoses and connectors. These hoses and connectors are designed to withstand the high pressures generated by the pump.

By following this process, a hydrostatic test pump converts mechanical energy from its power source into high-pressure liquid flow, enabling the pressurization of a system for leak detection and integrity evaluation.

Why Should You Perform Hydrostatic Testing?

Hydrostatic testing offers a multitude of benefits for ensuring the safety and integrity of pressurized systems. Key reasons to perform hydrostatic testing include:

- Leak Detection: The primary purpose of hydrostatic testing is to identify leaks within a pressurized system. By pressurizing the system beyond its normal operating pressure, even minute leaks become evident, allowing for timely repair and preventing potential failures during regular operation.

- Component Inspection: Hydrostatic testing can expose weaknesses or potential failure points in system components. This proactive approach allows for preventative maintenance and helps to avoid costly downtime and repairs in the future.

- Regulatory Compliance: In many industries, hydrostatic testing is mandated by regulatory standards to ensure adherence to safety protocols. These regulations are in place to safeguard personnel and property from potential hazards associated with pressurized system failures.

- Improved System Reliability: Regular hydrostatic testing contributes to the overall reliability of a pressurized system. By identifying and addressing potential issues before they escalate, hydrostatic testing helps to prevent unexpected system shutdowns and disruptions.

How to Operate Hydrostatic Test Pumps Safely?

Hydrostatic testing can be a safe and effective procedure when conducted with proper precautions. Here are some essential safety guidelines to follow when operating hydrostatic test pumps:

Before You Begin:

- Consult the Manufacturer’s Instructions: Always thoroughly read and understand the manufacturer’s instructions for your specific hydrostatic test pump model. These instructions will outline the pump’s pressure limitations, proper operation procedures, and safety precautions.

- Inspect the Pump: Prior to each use, thoroughly inspect the hydrostatic test pump for any signs of damage, leaks, or loose connections. Pay close attention to hoses, connectors, and pressure gauges. Damaged equipment should not be used and must be repaired or replaced by a qualified professional.

- System Preparation: Ensure the system under test is properly isolated and drained of any fluids or gases that may be incompatible with the testing liquid. Identify and secure any pressure relief devices on the system to prevent accidental actuation during testing.

- Personal Protective Equipment (PPE): Always wear appropriate PPE when performing hydrostatic testing. This typically includes safety glasses, gloves rated for the pressure being used, sturdy footwear, and hearing protection if the pump is particularly loud.

During Operation:

- Pressure Control: Gradually increase the pressure within the system to the desired test pressure level as specified by the system manufacturer or relevant regulations. Avoid exceeding the pressure limitations of the pump or the system under test.

- Leak Detection: Continuously monitor the system for leaks throughout the testing process. Utilize a visual inspection for water leaks and listen for any hissing sounds that may indicate air leaks.

- Pressure Maintenance: The pressure may fluctuate slightly during testing due to temperature changes or minor leaks. Be prepared to adjust the pump or close the isolation valve if necessary to maintain the desired test pressure.

After Testing:

- Pressure Release: Slowly and gradually release the pressure from the system using the pump’s pressure relief valve or a designated bleed-off valve on the system itself. Never open a pressurized connection or attempt to rapidly depressurize the system.

- System Inspection: Once the pressure has been released, perform a thorough inspection of the system for any signs of leaks, damage, or permanent deformation.

- Pump Maintenance: After each use, follow the manufacturer’s recommendations for cleaning, lubricating, and storing the hydrostatic test pump. This ensures the pump remains in optimal condition for future use.

Conclusion

Hydrostatic testing plays a crucial role in safeguarding the integrity of pressurized systems across various industries. By utilizing a hydrostatic test pump and adhering to proper safety protocols, operators can effectively identify and address potential leaks or weaknesses before they lead to catastrophic failures. Regularly conducted hydrostatic testing contributes to a safer working environment, minimizes downtime associated with equipment failures, and ensures optimal system performance. Remember, prioritizing safety is paramount when working with pressurized systems. By following the outlined safety guidelines and adhering to manufacturer instructions, hydrostatic testing can be a valuable tool for maintaining the reliability and safety of your pressurized equipment.