Hydrostatic and Gas Pressure Testing: How They Differ and When to Use Each

In various industries, testing the integrity and durability of equipment and components is crucial to ensuring safety, reliability, and performance. Two primary methods used for such testing are hydrostatic and gas pressure testing. Both techniques serve essential roles but are employed under different circumstances due to their distinct characteristics, safety considerations, and application scopes. This article delves into the specifics of hydrostatic and gas pressure testing equipment, their working principles, and the differences between the two.

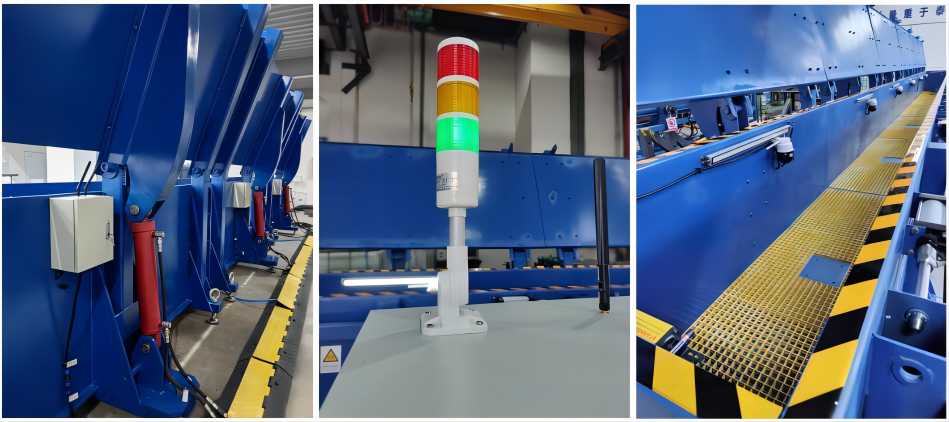

1. Characteristics of Hydrostatic Test Equipment

Hydrostatic test equipment is designed to assess the pressure resistance and structural integrity of vessels, pipelines, and other components that must withstand internal pressures during operation. Here are some key characteristics of hydrostatic test equipment:

- High-Pressure Components: Hydrostatic test equipment often incorporates welded connections in high-pressure sections to enhance strength and durability. This ensures the equipment can withstand the extreme pressures generated during testing without compromising integrity.

- User-Friendly Interface: Modern hydrostatic test equipment features intuitive control panels and simple operation, reducing the likelihood of errors and enhancing efficiency.

- Multiple Pipe Testing: The equipment can simultaneously test multiple pipes or components, saving time and labor costs in industries with high-volume testing requirements.

- Adjustable Pressure Holding Time: The duration of pressure application can be customized to meet specific testing needs, allowing for more rigorous evaluation of components.

2. Characteristics of Gas Pressure Testing Equipment

Gas pressure testing, like hydrostatic testing, is used to evaluate the integrity of equipment, but it employs gas (often compressed air or nitrogen) instead of water. The following are the key characteristics of gas pressure testing equipment:

- Gas-Driven High Pressure: Gas pressure equipment utilizes a large-area piston to drive low-pressure gas, generating high-pressure fluid, and enabling it to test components under extreme conditions.

- Output Pressure Matches the Driving Pressure: The pressure generated by the equipment is directly related to the pressure used to drive it, allowing for precise control during testing.

- Automatic Pressure Holding and Easy Maintenance: Many gas pressure testing systems feature automatic pressure holding functions and are designed for easy maintenance, ensuring reliable and cost-effective operation.

- Versatility with Different Gases: Gas pressure testing can be used with various gases, such as compressed air, nitrogen, or others, depending on the specific application.

3. Working Principles and Applications of Hydrostatic and Gas Pressure Testing

Hydrostatic and gas pressure testing are pivotal methodologies for evaluating the robustness and integrity of equipment under pressure. While their core objective is shared, the techniques diverge, each tailored to distinct applications and requirements.

3.1 Hydrostatic Testing

Hydrostatic testing harnesses the incompressibility of water to assess a component’s pressure resistance. Here’s how it operates:

- Simulation of Operational Conditions: Water is filled into the component, and its pressure is systematically escalated using a hydrostatic pump. This process mirrors the stresses the component will endure during its lifecycle.

- Monitoring with Precision: The setup includes a pressure pump, water reservoir, and a gauge to monitor internal pressures. A control system oversees the entire process, ensuring safety and accuracy.

- Pressure Escalation and Inspection: As the pump forces water into the component, pressure is increased to a predetermined level. The component is then scrutinized for leaks or signs of structural compromise.

- Assessment of Strength and Seals: Hydrostatic testing is a staple for evaluating the strength and sealing capabilities of various components, notably pressure vessels and pipelines. Its efficacy in identifying leaks is paramount to preventing critical failures.

3.2 Gas Pressure Testing

Contrastingly, gas pressure testing utilizes compressed gases to assess the integrity and mechanical properties of components. Its process and applications are outlined below:

- Gas Introduction and Pressurization: Gases like air or nitrogen are introduced into the component, which is then pressurized to the desired level. This step is crucial for monitoring the component for leaks or structural deformations.

- Energy from Gas Compression: A gas pressure pump is employed to compress the gas, which is subsequently forced into the component. As pressure rises, the component is tested to ensure it can handle the operational conditions it will encounter.

- Mechanical Property Evaluation: This method is particularly adept at assessing mechanical properties such as strength, stiffness, and elasticity. Components subject to dynamic loads or fluctuating pressures benefit greatly from this form of testing.

- Industrial Applications in Automotive and Beyond: Gas pressure testing is indispensable in the automotive industry, ensuring components like fuel tanks, brake systems, and new energy batteries are capable of withstanding the pressures they will face during use. Its applications extend to various sectors requiring rigorous testing standards.

Both testing methods are essential tools in the engineer’s arsenal, each offering unique insights into the reliability and safety of components under pressure.

4. Differences Between Hydrostatic and Gas Pressure Testing

Hydrostatic and gas pressure testing are both crucial methods for assessing equipment performance, but they differ in terms of safety, construction techniques, cost, and application.

4.1 Safety

- Hydrostatic testing is safer: Hydrostatic testing is generally considered safer because water is nearly incompressible. If a component fails during the test, the release of water is slow and controlled, reducing the risk of injury or damage.

- Gas pressure testing has explosion risks: Gas pressure testing, however, carries a higher risk due to the compressibility of gases. A failure under gas pressure can result in a sudden, explosive release of energy, making it more hazardous.

4.2 Construction Techniques

- Hydrostatic testing involves complex procedures: Hydrostatic testing requires careful setup, including sealing the equipment properly and removing air pockets that could affect the results. The testing environment must also be controlled to avoid contamination or temperature changes.

- Gas pressure testing needs a plan review: While gas pressure testing equipment setup is simpler, it requires thorough planning and safety reviews before testing. The potential risks involved with high-pressure gas make it essential to follow strict safety protocols.

4.3 Cost

- Gas pressure testing is more expensive: Gas pressure testing typically costs more than hydrostatic testing due to the need for specialized equipment and additional safety measures. These higher costs are often justified in situations where precision and safety are critical.

4.4 Application Range

- Hydrostatic testing for sealing performance: Hydrostatic testing is mainly used to check the sealing performance of components, such as pipelines and pressure vessels, where preventing leaks is vital.

- Gas pressure testing for mechanical properties: Gas pressure testing is better suited for evaluating the mechanical properties of components, such as strength and stiffness. It’s commonly used in industries where components must withstand dynamic loads and pressure variations.

To sum up, both hydrostatic and gas pressure testing play vital roles in ensuring the safety and reliability of equipment across various industries. Understanding the characteristics, working principles, and differences between these two methods is essential for selecting the appropriate testing procedure for a given application. Hydrostatic testing offers safety and cost-effectiveness for sealing performance evaluation, while gas pressure testing provides a precise and flexible approach to assessing mechanical properties.