Hydrogen High Pressure Shut-off Valve

- The threaded interface of the Hydrogen High Pressure Shut-off Valve (needle valve) adopts the high pressure instrument interface specified in API Spec 6A.

- The high pressure instrument interface is used in conjunction with the high pressure joint.

- The working medium of Hydrogen High Pressure Shut-off Valves (needle valve) can be hydraulic oil, water, gas, and most chemically corrosive liquids, which can meet the application of power stations, petroleum, chemical industry, new energy and other industries.

Share to

Overview

A Hydrogen High Pressure Shut-off Valve (needle valve) is a crucial safety component in fuel cell systems, hydrogen storage systems, and hydrogen refueling infrastructure. Its primary function is to quickly and reliably shut off the flow of hydrogen gas in the event of an emergency or malfunction, preventing the release of hydrogen (H2) into the atmosphere and minimizing the risk of fires or explosions.

In addition to its safety features, the Hydrogen High Pressure Shut-off Valve is designed for reliability and durability. The valve has undergone rigorous testing, including cycle life testing, pressure testing, and leak testing, to ensure its performance in demanding environments.

Typical applications for the Hydrogen High Pressure Shut-off Valve include fuel cell electric vehicles, hydrogen fueling stations, and industrial hydrogen production facilities. By providing a safe and reliable means of shutting off the hydrogen supply, this valve plays a vital role in promoting the widespread adoption of hydrogen fuel cell technology.

Features

- Non-rotating valve head is designed to improve the service life of the valve.

- The use of reinforced PTFE makes the sealing of the valve stem more reliable.

- Non-rotating valve needle can prevent packing wear and improve sealing performance.

- There are safety leakage holes between each connecting port and the sealing surface.

- Autoclave HP connection sealing structure design, with a maximum working pressure of 25,000 psi.

- The parts in contact with the medium are all made of 316L stainless steel, and the valve stem is made of special customized materials with excellent corrosion resistance.

- The metal-to-metal sealing form has good sealing effect and extends the service life of the valve stem and valve seat, ensuring the durability of the cycle switch.

- The sealing packing is located under the thread of the valve cap, and the thread does not come into contact with corrosive media, which improves the service life of the valve.

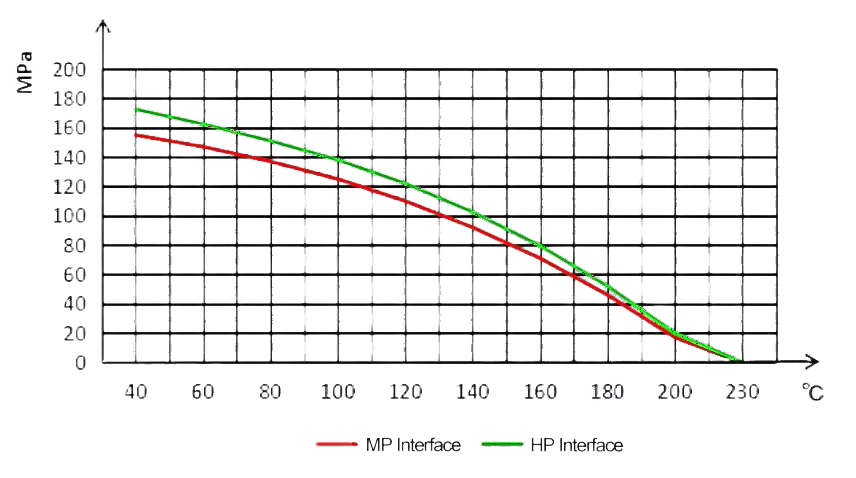

Temperature and Pressure Diagram

Series

| Medium | Hydraulic oil, water, gas, and most chemically corrosive liquids |

| Type of valve | Needle valve |

| Working Pressure | 1550 bar / 22,500 psi |

| Working Temp. Range | -45 to 230℃ |

| Interface Spec | 1/4″, 3/8″, 9/16″, 3/4″ |

| Material | High nickel 316L |

| Structure | Straight and Angle |

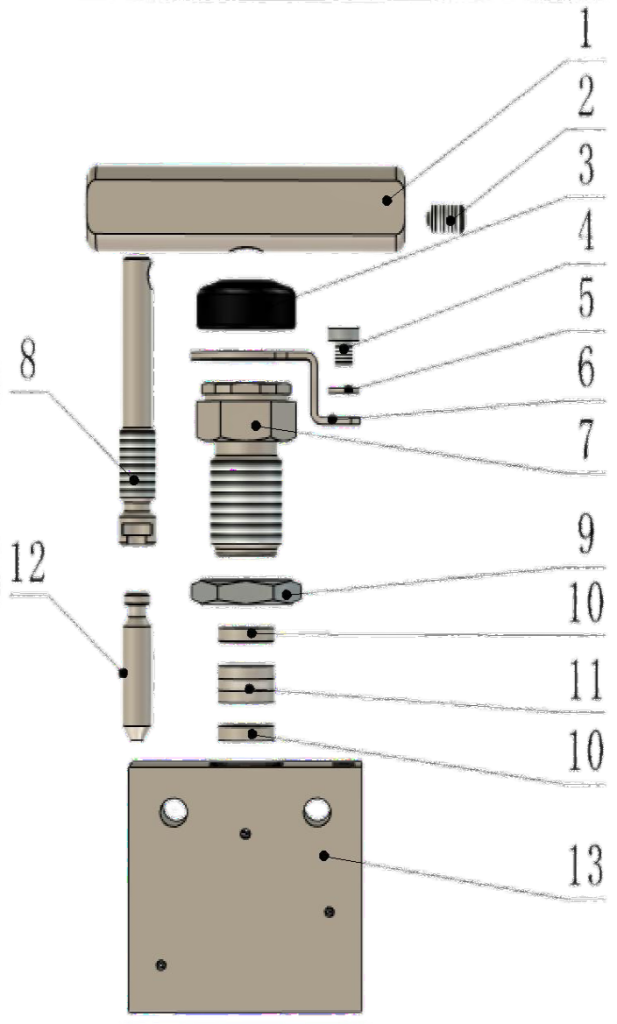

| No. | Part | Material |

| 1 | Handle | 304SS |

| 2 | Set Screw | 304SS |

| 3 | Dust Cover | POM |

| 4 | Internal Hexagonal Screw | 304SS |

| 5 | Spring Washer | 304SS |

| 6 | Anti-slip Slice | 304SS |

| 7 | Compression Nut | 316/316L |

| 8 | Actuator Stem | PH17-4 |

| 9 | Lock Nut | 304SS |

| 10 | Metal Washer | 316/316L |

| 11 | Packing | Reinforced PTFE |

| 12 | Sealing Stem | 316L |

| 13 | Body | A182/A479 F316L |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————