High-Pressure Ball Valves in the Gas and Oil Industry

The rumble of drilling rigs and the steady flow of fuel through pipelines paint a picture of the gas and oil industry – a world where precision control over immense pressures is paramount. Within this complex dance of extraction and transportation, a singular instrument reigns supreme: the high-pressure ball valve. These robust guardians of the flow deserve not just recognition, but a deep dive into their capabilities and significance.

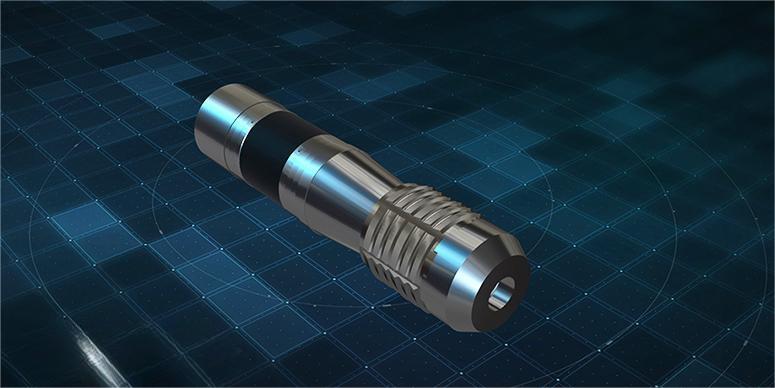

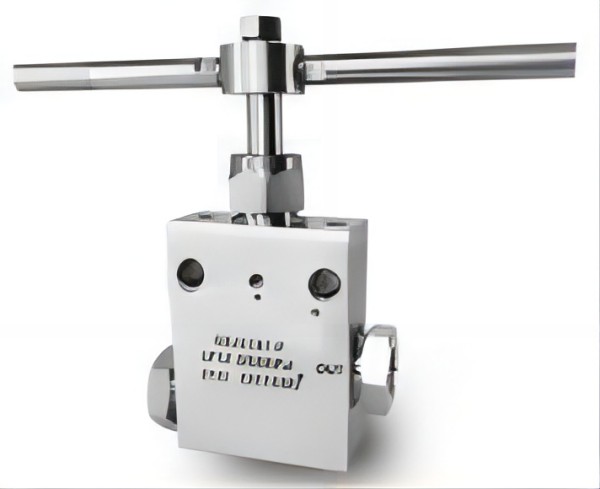

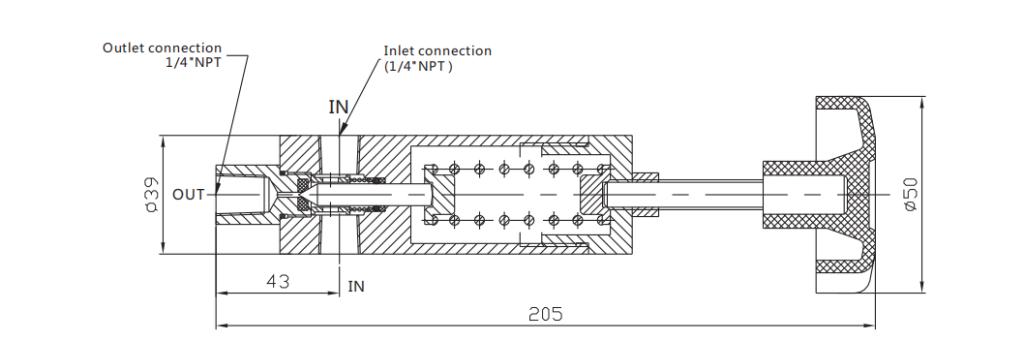

What is High Pressure Ball Valve?

High-pressure ball valves, unlike their everyday counterparts, are specifically designed to withstand immense internal pressures, often exceeding 10,000 psi (pounds per square inch). This makes them the gatekeepers of choice for pipelines transporting high-pressure gas and oil, ensuring their safe and controlled passage. Their robust construction, typically forged from high-grade steel or alloys, grants them exceptional strength and resistance to corrosion, making them impervious to the harsh chemical environments encountered in the industry.

The Advantages of High Pressure Ball Valve

In the gas and oil arena, where even the most minuscule leak can trigger a domino effect of safety and environmental repercussions, unwavering reliability reigns supreme. High-pressure ball valves, meticulously crafted to withstand the industry’s formidable demands, excel in this critical domain, offering a symphony of operational advantages:

1. Enduring Fortitude: These valves are architectural marvels, forged from high-alloy steels meticulously selected for their exceptional resistance to corrosion, fatigue, and the erosive nature of the fluids they regulate. This robust construction renders them impervious to the harshest environments, from searing deserts to frigid pipelines, ensuring dependable performance without succumbing to premature deterioration.

2. Leakproof Perfection: Unlike their intricate counterparts, high-pressure ball valves boast a deceptively simple yet remarkably effective design. The quarter-turn operation minimizes wear and tear on the sealing elements, resulting in leakage rates that approach the theoretical asymptote of zero. This translates to unparalleled safety, eliminating the specter of catastrophic accidents and safeguarding precious hydrocarbon resources from costly evaporation.

3. Maintenance Minimalism: Unlike their capricious, high-maintenance counterparts, high-pressure ball valves embrace the philosophy of simplicity. Their streamlined design and robust materials translate to a life of minimal intervention. Gone are the days of frequent servicing and part replacements, replaced by an era of unwavering dependability. This translates to reduced downtime, optimized operational efficiency, and ultimately, a healthier bottom line.

4. Flow Optimization: An Unfettered Passage: Unlike valves that constrict and impede the flow of precious resources, high-pressure ball valves boast a streamlined profile. The unobstructed path within the valve minimizes pressure drops, ensuring efficient fluid transportation. This translates to optimized system performance, minimizing energy consumption and maximizing the throughput of hydrocarbon reserves.

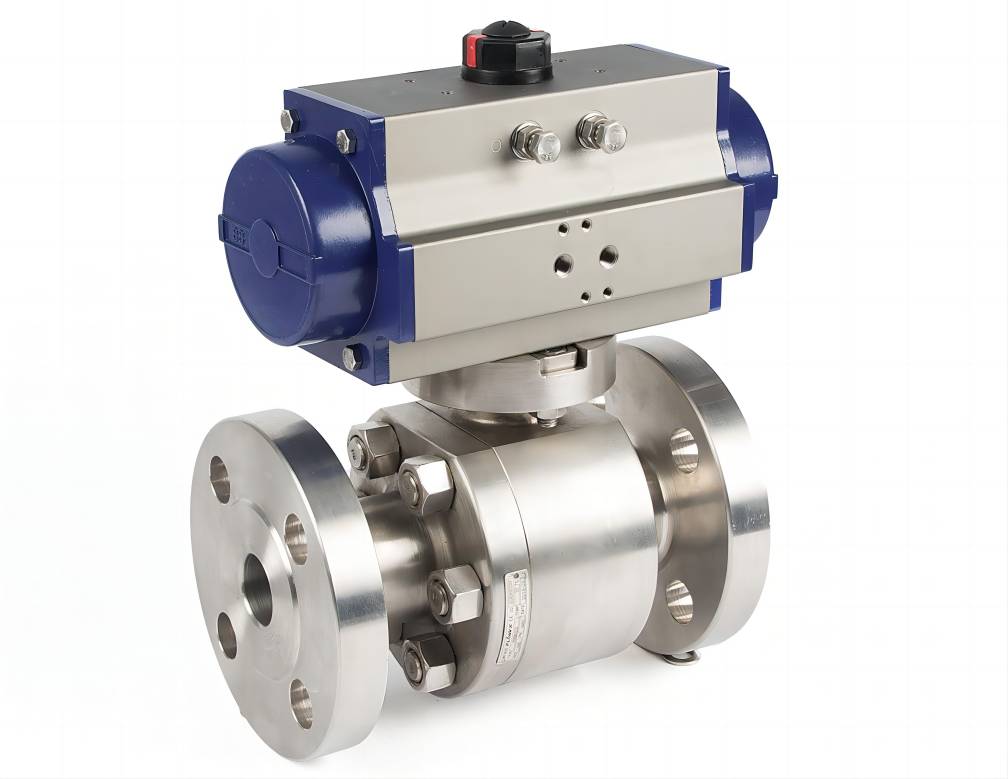

5. Unparalleled Versatility: High-pressure ball valves are not one-size-fits-all solutions. They come in a veritable orchestra of sizes, pressure ratings, and material compositions, each meticulously tailored to a specific application. From high-pressure pipelines spanning vast distances to the intricate web of valves within a bustling refinery, these adaptable performers seamlessly integrate into diverse operational settings, delivering reliable control across the entire hydrocarbon spectrum.

The Application of High Pressure Ball Valves in the Gas and Oil Industry

High-pressure ball valves are not merely passive bystanders in the gas and oil industry; they are active guardians, silently orchestrating the flow of precious resources at every crucial juncture. Their unwavering presence tames the mighty forces of pressurized hydrocarbons, ensuring safe and efficient operations across the entire hydrocarbon lifecycle.

1. Wellhead Control: At the epicenter of the operation, where the earth’s bounty erupts from the depths, high-pressure ball valves stand resolute. These valves, meticulously designed for high-pressure, high-temperature environments, control the initial surge of oil and gas, ensuring safe and controlled wellhead production. They act as the first line of defense, preventing uncontrolled releases and safeguarding personnel and equipment from the raw power of the wellbore.

2. Pipeline Protection: Once extracted, the hydrocarbons embark on a journey through the arteries of the industry: the vast network of pipelines. Here, high-pressure ball valves serve as vigilant sentinels, regulating the flow across vast distances. They ensure smooth and uninterrupted transportation, minimizing pressure drops and maximizing throughput. Their robust construction withstands the relentless pulsating pressure within the pipelines, preventing leaks and ensuring the secure delivery of resources to refineries and consumers.

3. Processing Precision: Within the intricate labyrinth of a refinery, where hydrocarbons undergo intricate transformations, high-pressure ball valves become masters of precision control. These valves regulate the flow through distillation columns, cracking units, and other processing equipment, ensuring precise flow rates and optimal process conditions. Their ability to handle diverse fluid compositions and operating pressures makes them invaluable partners in the delicate dance of refining crude oil into usable products.

4. Storage Protection: Finally, the journey culminates in storage facilities, where refined products await their final destination. High-pressure ball valves once again stand guard, ensuring the safe and secure storage of these valuable resources. They control the filling and emptying of tanks, preventing overfilling and ensuring controlled release during distribution. Their leakproof design and fire-safe options provide an additional layer of protection, safeguarding the integrity of stored products and minimizing environmental risks.

Conclusion

High-pressure ball valves are more than just valves; they are the unsung heroes of the gas and oil industry, whispering tales of control and progress amidst the roar of extraction and the hum of pipelines. From the rugged frontier of wellheads to the intricate dance of refineries, their unwavering presence ensures the safe and efficient flow of the resources that fuel our world. Their robust design, meticulous attention to detail, and unparalleled versatility have cemented their position as the champions of flow control, silently safeguarding our energy security and paving the way for a future powered by reliable, efficient hydrocarbon resources. As the industry evolves, so too will these tireless sentinels, adapting and innovating to meet the ever-changing demands of a world ever-thirsty for energy. In the symphony of the gas and oil industry, the high-pressure ball valve is not merely an instrument; it is the conductor, orchestrating the flow of progress with unwavering precision and silent dedication.