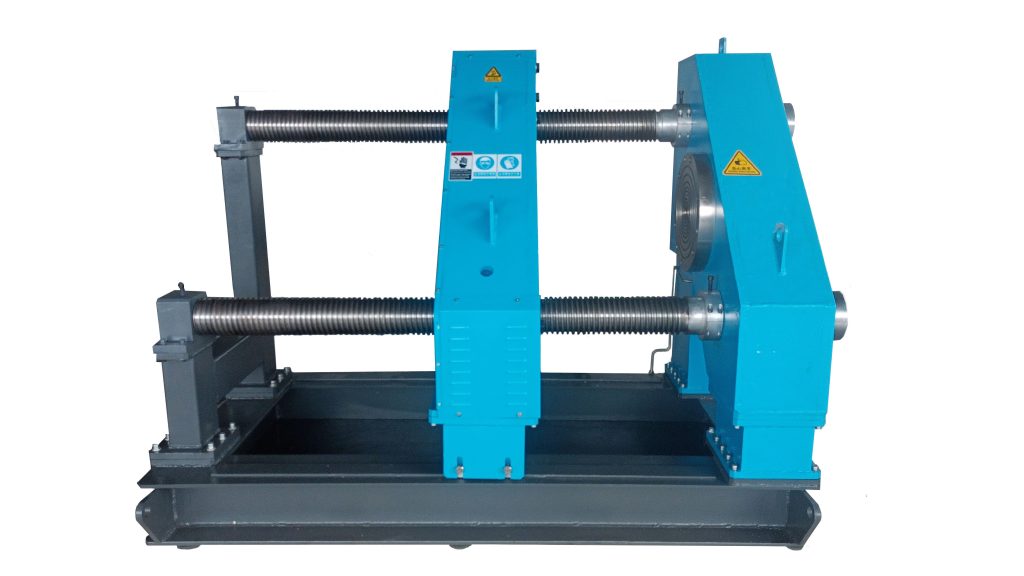

Gas and Liquid Pressure Testing Skid

- Model: WY-120/750N/1500W-J1

- It’s a crucial piece of equipment designed to perform burst pressure tests on various materials and components. The primary purpose of this equipment is to simulate extreme pressure conditions to determine the maximum pressure a material or component can withstand before failure.

Share to

Overview

This is a comprehensive pressure tester for multi-media pressurization that can output 120 bar of high pressure hydraulic oil, 750 bar of high pressure nitrogen and 1050 bar of high pressure water. Various booster functions can be realized through panel operation. At the same time, we can configure the electrification system developed by our company to realize fully automatic functions.

Feature

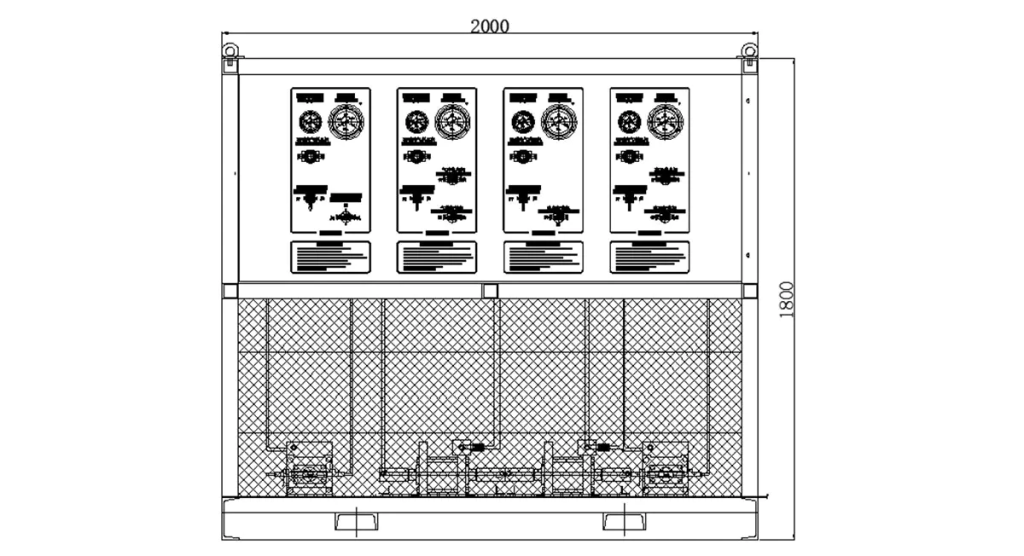

- The electrical component interfaces are placed in the explosion-proof box.

- Flow chart of boosting etched on the control panel surface of the booster unit.

- The multi-outlet combination panel enables real-time detection of multiple media and multiple workpieces at the same time.

- Adopts air-driven hydro pump as the boosting unit, which have pressure self-locking function and effectively avoid overpressure.

- The large-displacement low-pressure pump and the small-displacement high-pressure pump are configured to achieve functional control of different pressures, flow rate, and compression times.

Model: WY-120/750N/1500W-J1

Model:WY-120/750N/1500W-J1

Clear water test

| Test medium | Clear water |

| Max. output pressure of low pressure pump | 6Mpa |

| Max. output pressure of high pressure pump | 150Mpa |

| Output interface | G1/4-60° |

| Pipeline length | 15 meters (blue) |

| Pipeline pressure | 150Mpa |

| Number of output interfaces | 1 with 2 |

Gas pressure test

| Test medium | Nitrogen, air |

| Max output pressure | 75Mpa |

| Output interface | G1/4-60° |

| Pipeline length | 10 meters (color change) |

| Pipeline pressure | 75Mpa |

| Number of output interfaces | 1 with 1 |

| Nitrogen inlet line length | 10 meters (black) |

| Nitrogen inlet thread | G1/2 |

Hydraulic output

| Max. output pressure | 9Mpa |

| Interface size | M14*1.5 |

| Hydraulic line pressure | 25Mpa |

| Number of hydraulic lines | 4 each 15 meters (black) |

Structure

| Panel | Stainless steel |

| Water tank | Stainless steel |

| Pressure gauge | Stainless steel |

| Valve | Stainless steel |

| Tube | Stainless steel |

| Connector | Stainless steel |

| Hydraulic cylinder | Anodized aluminium |

| Piston | Stainless steel |

| Pump head | Stainless steel |

| Frame | Carbon steel |

Hydraulic Oil Pressure Static Conditions (@7bar)

| Air pressure (bar) | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Hydraulic pressure (bar) | 0 | 10 | 20 | 36 | 40 | 50 | 60 | 70 |

| Output flow rate (L/min) | 35 | 30 | 24 | 36 | 48 | 60 | 72 | 84 |

Water Pressure Static Conditions (@7bar)

| Air pressure (bar) | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Hydraulic pressure (bar) | 0 | 100 | 250 | 500 | 7500 | 12500 | 1500 | 1750 |

| Output flow rate (L/min) | 0.77 | 0.65 | 0.5 | 0.43 | 0.38 | 0.34 | 0.26 | 0.2 |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————