Explosion-Proof Pressure Testbay Boxes: Safeguarding Testing in Hazardous Environments

Ensuring the safety and reliability of equipment in industries like oil and gas, chemical processing, and aerospace is paramount. One crucial aspect of this involves pressure testing, where components and systems are subjected to controlled pressure beyond their normal operating limits to evaluate their integrity and performance. However, when dealing with potentially volatile materials or environments, conventional pressure testing equipment poses significant safety risks. This is where explosion-proof pressure testbay boxes (PTBs) come into play.

Understanding the Need for Explosion-Proof Pressure Testing

During conventional pressure testing, a minuscule leak or rupture could ignite surrounding flammable gases, leading to a rapid escalation in pressure and a devastating explosion. The resulting shockwave and fire could endanger personnel in the immediate vicinity, potentially causing widespread damage to surrounding infrastructure and inflicting significant environmental harm.

Explosion-proof Pressure Testbay Boxes (PTBs) were specifically engineered to mitigate these risks by providing a meticulously controlled environment for pressure testing equipment within potentially hazardous settings. By isolating the test object from the external environment, PTBs effectively contain any potential failure or release of volatile substances, preventing the propagation of an uncontrolled event.

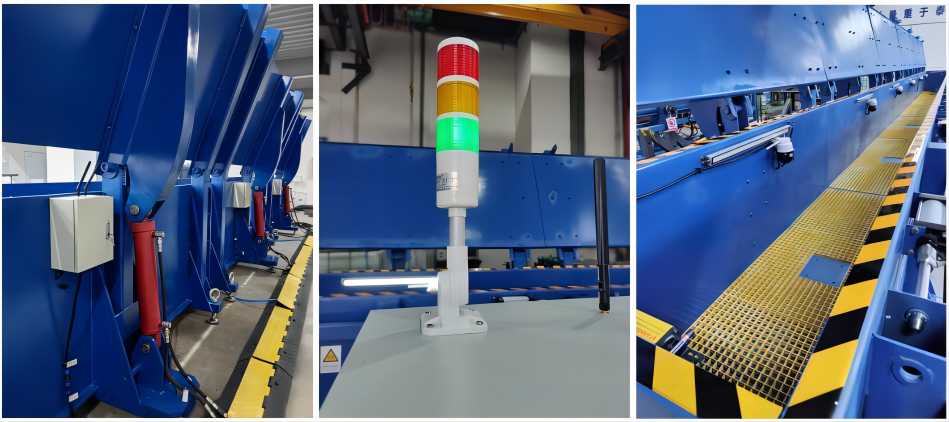

Components of an Explosion-Proof Pressure Testbay Box

A well-conceived PTB is not merely a conglomeration of parts; it is a meticulously orchestrated symphony of interdependent components, each playing a vital role in safeguarding the pressure testing process within potentially volatile environments. Here, we dissect the key elements that contribute to the PTB’s exceptional safety and efficacy:

1. Pressure Vessel: The Impregnable Core

The pressure vessel serves as the robust heart of the PTB, where the test object undergoes rigorous pressure evaluation. Constructed from high-tensile materials like carbon steel or stainless steel, the vessel is engineered to withstand the maximum test pressure without yielding or compromising its structural integrity.

- Wall Thickness: The vessel’s wall thickness is meticulously calculated to resist the anticipated pressure load, ensuring it remains structurally sound throughout the testing cycle.

- Weld Integrity: Impeccable weld quality is paramount, achieved through stringent welding procedures and non-destructive testing techniques to eliminate potential weak points.

- Pressure Relief Mechanisms: Redundant pressure relief valves and rupture disks act as fail-safe mechanisms, automatically venting excess pressure and preventing catastrophic vessel failure.

2. Pressure Generation and Control System: The Orchestrator of Pressure

This system meticulously delivers and maintains the desired pressure within the vessel. Depending on the application, various methods may be employed:

- Hydraulic Pumps: High-pressure hydraulic pumps utilize incompressible fluids to generate precise and controllable pressure levels.

- Air Compressors: Compressed air offers a versatile and readily available option for pressure generation, particularly suited for moderate pressure requirements.

- Gas Boosters: When dealing with highly compressible gases, specialized gas boosters provide the necessary force to achieve the desired pressure levels.

The system further incorporates:

- Pressure Regulators: These fine-tune the pressure delivered to the vessel, ensuring precise control and adherence to test protocols.

- Valves: Bidirectional valves facilitate pressure manipulation, enabling controlled filling, venting, and isolation of the test object.

- Safety Interlocks: These intelligent systems automatically halt the testing process if preset pressure, temperature, or other parameters are exceeded, preventing potential accidents.

3. Monitoring and Data Acquisition System: The Vigilant Eye

Real-time monitoring of vital parameters is crucial for ensuring the safety and efficacy of the testing process. PTBs leverage a network of sensors and transducers to gather critical data, including:

- Pressure Sensors: These accurately measure the pressure within the vessel, providing continuous feedback on the testing progress.

- Temperature Sensors: Monitoring temperature is crucial, as excessive heat can compromise the vessel’s integrity or trigger unintended reactions in the test object.

- Strain Gauges: These sensors detect minute deformations in the vessel wall, providing early warning of potential structural weaknesses.

The collected data is then processed and displayed on a central control panel or recorded for further analysis. This valuable information facilitates:

- Real-time monitoring and assessment of the test object’s performance.

- Identification of potential anomalies or weaknesses before they escalate into critical failures.

- Generation of detailed reports for post-test analysis and documentation.

4. Explosion-Proof Components: The Shields against Ignition

Traditional pressure switches and sensors pose inherent risks in hazardous environments due to their potential for generating sparks or overheating. Explosion-proof PTBs address this concern by employing intrinsically safe components specifically designed to eliminate any potential ignition sources. These components undergo rigorous testing and certification to meet stringent international safety standards like IECEx, ATEX, and API.

- Explosion-Proof Pressure Switches: These utilize hermetically sealed enclosures, intrinsically safe materials, and magnetic or optical actuation mechanisms to eliminate the risk of electrical sparks.

- Explosion-Proof Pressure Sensors: These employ robust pressure-transmitting mediums like capillary tubes or diaphragms, isolating the sensor element from the potentially flammable environment.

Applications of Explosion-Proof Pressure Testbay Boxes in the Gas and Oil Industry

The gas and oil industry operates in an environment rife with volatile substances and high-pressure systems, necessitating meticulous safety protocols and robust testing procedures. Explosion-proof PTBs play a pivotal role in mitigating risks and ensuring the integrity of critical equipment in this demanding domain. Their applications encompass a vast array of essential tasks, safeguarding both personnel and infrastructure:

1. Pipeline Integrity Evaluation

- High-Pressure Pipelines: PTBs facilitate the safe and controlled pressure testing of high-pressure pipelines, verifying their ability to withstand operational pressures without leaks or ruptures. This proactive approach mitigates the risk of catastrophic pipeline failures, safeguarding nearby communities and the environment.

- Subsea Pipelines: PTBs can be specially designed and deployed for subsea pipeline testing, ensuring structural integrity and leak detection in these challenging underwater environments.

- Material Compatibility Testing: PTBs facilitate the assessment of material compatibility under high pressure and specific fluid conditions, informing pipeline construction and maintenance decisions.

2. Wellhead Equipment Testing

- Blowout Preventers (BOPs): PTBs provide a safe environment for pressure testing BOPs, critical safety devices that prevent uncontrolled wellbore fluids from erupting. This ensures their functionality and reliability in the event of an emergency.

- Christmas Tree Valves: PTBs enable the safe and controlled pressure testing of Christmas tree valves, complex systems regulating wellbore fluid flow at the surface. This verifies their operational integrity and prevents potential leaks or malfunctions.

- Wellhead Connectors: PTBs facilitate the pressure testing of wellhead connectors, ensuring their ability to withstand operational pressures and maintain fluid isolation.

3. Pressure Vessel and Tank Evaluation

- Storage Tanks: PTBs enable the safe and controlled pressure testing of storage tanks for hydrocarbon liquids and gases, verifying their structural integrity and leak detection capabilities. This safeguards against potential ruptures and environmental contamination.

- Processing Vessels: PTBs facilitate the pressure testing of process vessels employed in refining and petrochemical processing, ensuring their ability to withstand operational pressures and prevent unintended chemical reactions.

- Pressure Relief Valves: PTBs enable the safe and controlled testing of pressure relief valves, ensuring their timely activation and effectiveness in preventing vessel over-pressurization events.

4. Research and Development Applications

- New Material Evaluation: PTBs provide a controlled environment for evaluating the performance of new materials and components under high pressure and hazardous conditions, driving innovation in pipeline and equipment design.

- Process Optimization Testing: PTBs facilitate the safe testing of different operating parameters and fluid mixtures, optimizing production processes and maximizing efficiency in gas and oil operations.

- Failure Analysis and Root Cause Investigation: PTBs can be used in controlled settings to recreate and analyze potential failure scenarios, providing valuable insights for incident investigation and future risk mitigation strategies.

Beyond these specific applications, the overarching value of PTBs in the gas and oil industry lies in their ability to:

- Enhance operational safety: By proactively identifying and addressing potential equipment failures, PTBs significantly reduce the risk of accidents and environmental incidents.

- Optimize asset lifespan: Thorough pressure testing enables early detection of equipment degradation and facilitates timely maintenance, extending the service life of critical assets.

- Boost confidence in infrastructure: PTBs provide demonstrable evidence of equipment integrity and operational reliability, fostering trust and confidence within the industry and regulatory bodies.

Prioritizing Safety in Explosion-Proof Pressure Testbay Box Operations

Operating PTBs in potentially volatile environments necessitates a rigorous commitment to safety, governed by meticulous procedures, comprehensive training, and unwavering adherence to stringent regulations. To ensure the safe and effective execution of pressure testing, several key considerations must be prioritized:

1. Personnel Competence and Training

- Operator Qualification: Only duly trained and qualified personnel certified in PTB operation, safety protocols, and emergency response procedures should be authorized to conduct testing. This encompasses theoretical knowledge of PTB functionality, risk mitigation strategies, and practical expertise in equipment setup, operation, and emergency response.

- Continuous Training and Refresher Courses: Ongoing training programs and refresher courses are essential to ensure personnel remain proficient in safe PTB operation and equipped to handle unforeseen situations. This includes updates on evolving best practices, potential hazard identification, and emergency response drills.

2. Rigorous Maintenance and Preventative Measures

- Scheduled Inspections and Maintenance: Implementing a comprehensive schedule for regular inspections and preventive maintenance of all PTB components is crucial. This includes visual inspections, functionality checks, calibration of sensors and gauges, and replacement of worn or damaged parts to ensure system integrity and prevent potential equipment failures.

- Auditing and Documentation: Maintaining detailed records of inspections, maintenance activities, and test protocols is essential for ensuring operational transparency and identifying areas for improvement. Regular audits by qualified personnel further elevate safety standards by verifying adherence to established procedures and detecting potential issues.

3. Comprehensive Emergency Preparedness

- Emergency Response Plans: Clearly defined and readily accessible emergency response plans tailored to specific potential incident scenarios are critical. These plans should outline roles and responsibilities, evacuation procedures, communication protocols, and deployment of safety equipment for prompt and effective emergency response.

- Drills and Simulations: Conducting regular drills and simulations incorporating various emergency scenarios provides personnel with firsthand experience in implementing the emergency response plan, enhancing their preparedness and reaction time in real-world situations.

- Readily Available Safety Equipment: Ensuring immediate access to appropriate personal protective equipment (PPE), fire suppression systems, spill containment materials, and first-aid kits is vital for mitigating the consequences of potential incidents and safeguarding personnel.

4. Adherence to Relevant Regulations and Standards

- Industry-Specific Regulations: PTB operations must comply with relevant safety regulations and standards applicable to the specific industry and application. This entails adhering to established guidelines for pressure testing protocols, equipment specifications, personnel qualifications, and emergency response procedures. Examples include API standards for the oil and gas industry, ATEX and IECEx directives for hazardous environments in Europe, and OSHA regulations in the United States.

- Certification and Compliance Verification: Utilizing PTBs certified by independent bodies accredited against relevant standards provides assurance of their design, manufacturing, and operational compliance with safety requirements. Regularly verifying compliance through audits and inspections assures continued adherence to established safety protocols.

Conclusion

Explosion-proof pressure testbay boxes are not just equipment; they are vital safety tools that enable safe and reliable testing in hazardous environments. By understanding their components, applications, and safety considerations, we can leverage their capabilities to ensure the integrity of critical equipment and protect personnel, ultimately safeguarding lives and assets across diverse industries. As we step into the future of pressure testing, embracing continuous innovation and prioritizing safety will be paramount in ensuring the continued effectiveness and reliability of these crucial systems. By investing in advanced technologies, fostering a culture of safety awareness, and adhering to stringent regulations, we can harness the power of explosion-proof PTBs to push the boundaries of safety and performance, paving the way for a more secure and prosperous future for all.