Enhancing Nitrogen Pressure with Nitrogen Booster Systems and Gas Boosters

Nitrogen, an essential element, finds its applications in various industries, including oil and gas, chemicals, food and beverage, electronics, and more. To ensure optimal performance, nitrogen pressure needs to be boosted in certain processes. This is where nitrogen booster systems and gas boosters play a crucial role. In this article, we will explore the components, working principles, applications, benefits, and considerations for selecting a nitrogen booster system.

What Is Nitrogen Booster Systems?

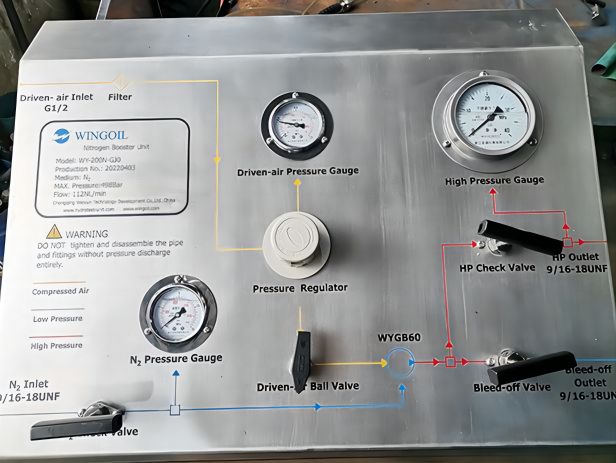

A nitrogen booster system is designed to increase nitrogen pressure, enabling efficient delivery and utilization in various applications. It consists of two key components: gas boosters and nitrogen pressure boosters. Gas boosters, also known as gas amplifiers, are responsible for compressing gases, including nitrogen. They use compressed air or hydraulic power to deliver high-pressure gas output. Nitrogen pressure boosters, on the other hand, focus specifically on enhancing the pressure of nitrogen gas.

Working Principle of Nitrogen Booster Systems

The nitrogen booster system operates through a series of steps. First, the gas booster receives low-pressure nitrogen gas and compresses it. This compressed gas is then directed to the nitrogen pressure booster, which further increases the pressure to the desired level. The system is equipped with safety features, such as pressure relief valves and interlocks, to ensure safe operation.

Applications of Nitrogen Booster Systems

Nitrogen booster systems find applications across various industries. In the oil and gas industry, these systems are used for wellhead control, gas lifting, and nitrogen injection for enhanced oil recovery. The chemical industry relies on nitrogen booster systems for inerting and blanketing applications to prevent oxidation and preserve product quality. In the food and beverage industry, nitrogen is used for packaging, purging, and pressurization. Additionally, the electronics industry utilizes nitrogen booster systems for soldering and wave soldering processes.

Nitrogen booster systems play a crucial role in the gas and oil industry, offering a range of applications that contribute to efficient operations and safety measures.

One key application is nitrogen purging. In the gas and oil industry, pipelines, tanks, and vessels often require purging to remove contaminants, moisture, or hazardous gases. Nitrogen booster systems are employed to provide high-pressure nitrogen gas for purging operations, ensuring a clean and safe environment for handling and transporting hydrocarbons.

Another vital application is nitrogen pressure testing. Before commissioning pipelines, valves, and other equipment, they need to undergo rigorous pressure testing to verify their integrity. Nitrogen booster systems are used to pressurize the systems with nitrogen gas, allowing for precise and controlled testing to ensure structural integrity and detect potential leaks.

In the gas and oil industry, nitrogen is also utilized for well-stimulation. Nitrogen gas can be injected into oil or gas wells to enhance production by reducing the viscosity of oil or breaking up formations that restrict the flow. Nitrogen booster systems provide the necessary high-pressure nitrogen to facilitate effective well-stimulation processes, leading to increased production rates and improved reservoir performance.

Furthermore, nitrogen booster systems are employed in nitrogen-assisted drilling. This technique involves injecting nitrogen gas into drilling mud to reduce the weight and pressure exerted on the wellbore during drilling operations. The nitrogen booster systems provide the required high-pressure nitrogen to ensure smooth and efficient drilling, reducing the risk of wellbore instability and enhancing drilling performance.

Lastly, nitrogen booster systems find applications in pipeline maintenance and pigging operations. Nitrogen gas is used to propel pipeline pigs, which are devices inserted into pipelines for cleaning, inspection, and maintenance purposes. The high-pressure nitrogen from booster systems assists in propelling the pigs through the pipelines, facilitating efficient cleaning and inspection operations.

The applications of nitrogen booster systems in the gas and oil industry contribute to safe, efficient, and productive operations. Whether it’s purging, pressure testing, well stimulation, nitrogen-assisted drilling, or pipeline maintenance, these systems play a crucial role in maintaining the integrity of equipment, optimizing production, and ensuring the smooth flow of hydrocarbons.

Benefits and Advantages of Nitrogen Booster Systems

Implementing a nitrogen booster system offers several benefits. Firstly, it improves efficiency and productivity in processes that depend on nitrogen. By ensuring adequate pressure, the system enables optimized performance and consistent results. Secondly, it leads to cost savings by optimizing nitrogen usage and minimizing waste. Moreover, nitrogen booster systems enhance safety and reliability by maintaining a controlled and stable nitrogen supply. They also provide flexibility and adaptability to cater to diverse industry needs.

Considerations for Selecting a Nitrogen Booster System

When selecting a nitrogen booster system, several factors need to be considered. Firstly, the flow rate and pressure requirements of the specific application must be assessed. This ensures that the selected system can meet the demands effectively. Compatibility with existing nitrogen systems is also essential for seamless integration. Evaluating the maintenance and serviceability aspects of the system helps in determining its long-term viability. Additionally, the presence of safety features and relevant certifications ensures compliance with industry standards and regulations.

Conclusion

Nitrogen booster systems, in combination with gas boosters and nitrogen pressure boosters, play a vital role in enhancing nitrogen pressure for various applications. From industries like oil and gas, chemicals, food and beverage, and electronics, to medical and automotive sectors, these systems provide efficiency, cost savings, safety, and flexibility. When choosing a nitrogen booster system, evaluating flow rate, pressure requirements, compatibility, maintenance, and safety features are crucial. As industries continue to rely on nitrogen, exploring and adopting nitrogen booster systems is key to achieving optimal performance and desired results.