Do You Know About The Pressure Test Pump?

What is a pressure test pump?

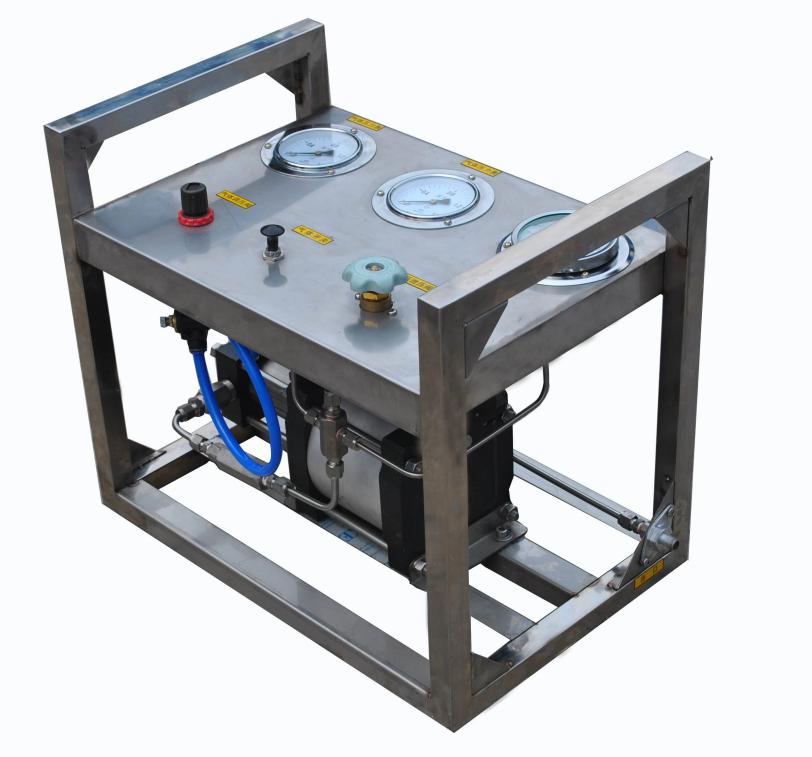

The pressure test pump is specially designed for various types of pressure vessels, pipelines, valves, boilers, steel cylinders, fire equipment, etc. for hydraulic testing and testing equipment for obtaining high-pressure liquids in the laboratory. The material of the pump can be stainless steel (SS 316 or SS 304), cast iron, etc. It depends on the pump application. Normal use of 316 stainless steel in the water industry and pharmaceutical applications, such as stainless steel, produces better results at high temperatures. WINGOI pressure test pump has the characteristics of compact and reasonable structure, labor-saving operation, light weight of the whole machine, convenient maintenance, and greatly improved work efficiency.

How does the pressure test pump operate?

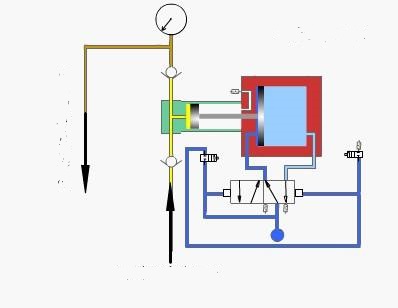

Its function is to convert the mechanical energy of power machines (such as electric motors and internal combustion engines) into the pressure energy of liquids. Working principle: The cam is driven by the motor to rotate. When the cam pushes the plunger to move upward, the sealing volume formed by the plunger and the cylinder is reduced, and the oil is squeezed out from the sealing volume and discharged to the required place through the one-way valve. When the cam rotates to the descending part of the curve, the spring forces the plunger down, forming a certain degree of vacuum, and the oil in the tank enters the sealing volume under the action of atmospheric pressure. The cam makes the plunger rise and fall continuously, the sealing volume decreases and increases periodically, and the pump continuously absorbs and discharges oil.

The role of the pressure test pump

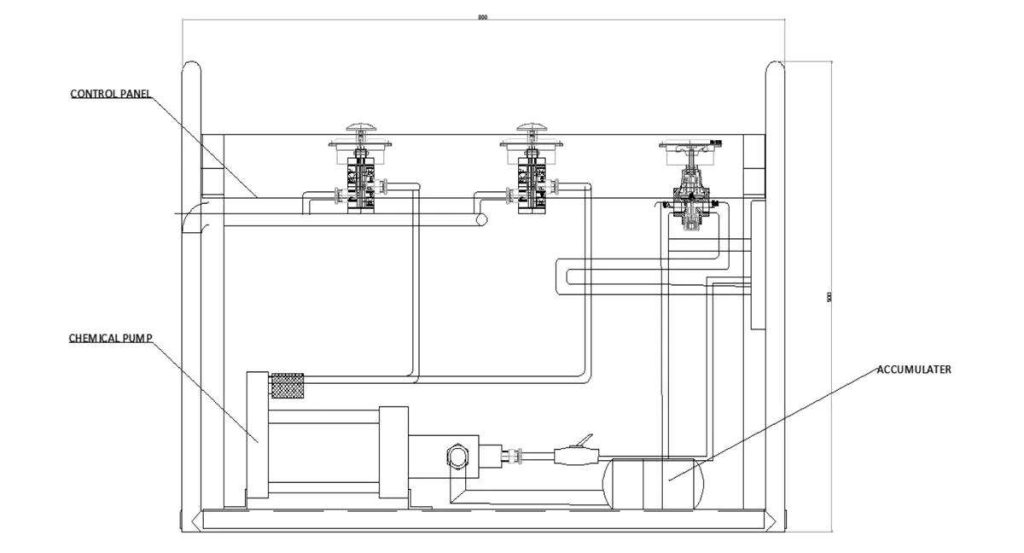

It is mainly used as a piece of pressurizing equipment for various pressure vessels and equipment (such as chemical containers, pumps, valves, pipes, etc.) when testing pressure. Therefore, the characteristic of the pressure test pump is that the discharge pressure is very high. Generally, the pressure test pump reaches several hundred atmospheres, and the ultra-high pressure test pump reaches tens of thousands of atmospheres, and the flow rate is generally small, mostly less than 1m3/h. However, the small output flow will not increase the time required for the pressure test, because the pressure test of the container is not completed after the pressure test pump is filled. Usually, the pressure test process is to fill the container with liquid first, and then leave the joint to connect to the pressure test pump outlet. Using the principle that the liquid has the same value to transmit the force when the outlet of the pressure test pump reaches a certain pressure value, the container is also subjected to this pressure correspondingly, to achieve the purpose of the test pressure.

The pressure test pump is suitable for water or hydraulic oil as a medium and is suitable for various pressure vessels. Pipes, valves, etc. are pressure tested, and also used as hydraulic energy to provide the required pressure, suitable for chemical, construction, plumbing, petroleum, coal, smelting, shipbuilding, and other industries.

Pressure test pump safety operation rules

1. Carry out the pressure test in strict accordance with the pressure test requirements, and the pressure test parts should be neat, clean and easy to inspect.

2. Before the pressure test, check the electrical system and grounding conditions, check the pressure gauge, check whether the pressure test pump is running and lubricated well, and the maximum degree of the pressure test gauge is not less than 1.5 times the test pressure.

3. In the preparatory work for the pressure test, the positions of the water inlet and the water outlet should be arranged. When the pressure test is filled with water, the vent hole should be opened first, and the pressure gauge should be removed to let the air in the container clean. , reload the table, and close the vents.

4. The pressure increase must be slow and no overpressure is allowed. After the pressure test piece rises to a certain pressure, it is forbidden to beat it. If defects are found in the test pieces and pipelines, they should be depressurized to zero before treatment, and work under pressure is not allowed.

5. The negative pressure and low-pressure test pieces and small containers can be boosted to a certain pressure at one time, and then the pressure is maintained for inspection. Large-volume specimens can be boosted and checked in stages.

6. The pressure test piece must be placed stably, and the pressure test part shall not leak after inspection.

7. After the pressure test is over, drain the water first, release the pressure, and then remove the bolts. After the pressure test in winter, the water must be drained immediately to prevent the equipment from being damaged by freezing.

8. The tightening bolts should be uniformly stressed to prevent local deformation and rupture.

9. The pressure test pump should be operated by a special person, and there must be more than two people for each pressure test, and a special person should be instructed to stick to the post before the water is released.

10. Mark the inspected defective parts and fill in the pressure test record.