Dissolvable Magnesium Alloy in Modern Oil and Gas Extraction

In modern oil and gas extraction, fracturing (frac) operations play a crucial role in enhancing production. To optimize these operations, various innovative materials and tools have been developed. Among these, dissolvable frac balls have emerged as a significant innovation. These frac balls, made from dissolvable magnesium alloy, can automatically dissolve under downhole conditions, facilitating the removal of tools post-frac operations. This article delves into the material properties, applications, and advantages of dissolvable magnesium alloy in oil and gas extraction.

Material Properties and Applications

Dissolvable frac balls primarily consist of elements like aluminum (Al), zinc (Zn), lanthanum (La), tin (Sn), and gallium (Ga). The weight percentage ranges for these elements are aluminum 3.5-7.5wt%, zinc 0.5-2.0wt%, lanthanum 0-0.05wt%, tin 0.1-0.3wt%, and gallium 0.5-2.5wt%.

To meet the demands of oil and gas well fracturing operations, dissolvable frac balls need to have the following properties:

- Low Density: A density range of 1.73-2.70 g/cm³ ensures the frac balls can be pumped downhole with drilling fluid.

- High Strength: An ultimate strength of not less than 450 MPa to withstand high-pressure downhole environments.

- Controlled Dissolution Rate: The ability to quickly dissolve after the completion of frac operations to avoid contaminating the oil and gas resources.

These performance requirements ensure the reliability of the frac balls during operations and their swift dissolution afterward, preventing contamination.

Widespread Application of Dissolvable Magnesium Alloy

High-strength dissolvable magnesium alloy materials have been developed for a range of fracturing tools, including dissolvable bridge plugs, delayed dissolvable toe-end sleeves, and dissolvable ball seats. In China, these tools are used in over 80% of shale oil and gas segment tools, highlighting their importance and widespread application in modern fracturing technology.

Role of Dissolvable Frac Balls in Fracturing Operations

In fracturing operations, dissolvable frac balls primarily serve as packers. Here is how they function:

- Sealing Wellbore Pores: The frac balls are placed at predetermined packing positions, blocking certain wellbore pores to ensure fracturing fluid only enters unblocked pores. This creates one or multiple fracturing stages.

- Controlling Fracturing Fluid Distribution: By acting as packers, the frac balls effectively control the distribution of fracturing fluid, ensuring efficient and effective fracturing operations.

After the fracturing operation, downhole conditions (such as injecting acid or changing temperature) are adjusted to dissolve the magnesium alloy frac balls, removing the packers and restoring wellbore flow for subsequent oil or gas production.

Enhancing the Performance of Dissolvable Magnesium Alloy Frac Balls

The performance of dissolvable frac balls can be improved by adjusting their material composition. The aluminum content significantly affects the microstructure, dissolution performance, and mechanical properties of the dissolvable magnesium alloy:

- Effect of Aluminum Content: As the aluminum content increases, the amount of β-Mg17Al12 phase increases, forming a continuous network at the α phase grain boundaries, while the α grains become coarser. This microstructural change helps increase the dissolution rate. Studies show that within a certain range, the dissolution rate increases with aluminum content, reaching an optimal value before potentially decreasing. Additionally, the compressive strength of the alloy is influenced by the aluminum content, with an appropriate amount providing high compressive strength, but too much aluminum can reduce plasticity.

- Optimizing Aluminum Content: Through experimental research, the optimal aluminum content can be determined to achieve an alloy with both excellent dissolution performance and sufficient plasticity. Frac balls made from such alloys are better suited for fracturing operations, ensuring safety while improving operational efficiency.

Specific Applications of Dissolvable Magnesium Alloy in Oil and Gas Extraction

Use of Dissolvable Frac Balls

Dissolvable frac balls are used in multi-stage hydraulic fracturing operations. They are placed in pre-drilled guide holes, and as pressure increases, the frac balls break, releasing the guide holes. Subsequently, high-pressure fluid flows through these newly opened fractures into the reservoir, causing fractures to extend and branch, increasing the storage space.

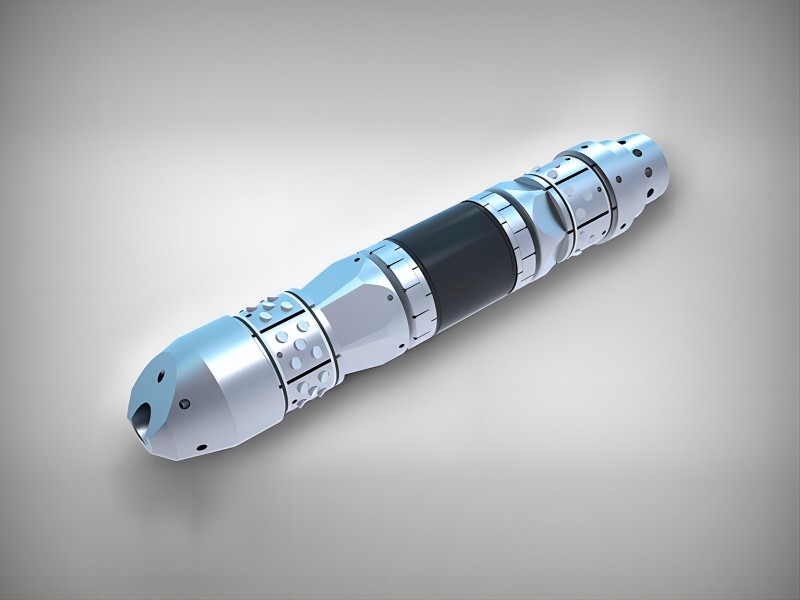

Use of Dissolvable Bridge Plugs

Bridge plugs are used to seal non-productive layers or fractures in oil wells to prevent premature fluid backflow or maintain the pressure of artificial fractures. They are placed at certain stages or after fracturing operations and dissolve under appropriate chemical or temperature conditions, restoring the production path of the well.

Working Principle of Dissolvable Magnesium Alloy

The selection of dissolvable magnesium alloy is based on its dissolvability under specific conditions. In oil and gas wells, magnesium alloy can resist the initial acidic environment but starts dissolving upon reaching the predetermined depth or temperature. This dissolution process is controllable and can be initiated or accelerated by adjusting wellbore conditions. After dissolution, the magnesium alloy no longer obstructs the flow of oil and gas, thereby increasing recovery rates.

In practical applications, the formulation and manufacturing process of the magnesium alloy is optimized to enhance its mechanical properties and dissolution behavior to meet the specific requirements of different oil fields. For instance, adding zinc elements and optimizing heat treatment processes can produce high-strength magnesium alloys with excellent dissolution properties, meeting the needs of industrial-scale production and application.

Reasons Why Dissolvable Magnesium Alloy is Environmental Friendliness

- Automatic Dissolution: Dissolvable magnesium alloy bridge plugs can automatically dissolve after fracturing operations, reducing additional workload and environmental pollution associated with traditional metal bridge plug removal.

- Eco-Friendliness: Compared to metals like cast iron and aluminum, magnesium is more environmentally friendly because it degrades more easily under natural conditions, reducing the potential impact on ecosystems.

- Pollution Reduction: Dissolvable magnesium alloy bridge plugs do not leave behind debris that could contaminate reservoirs, unlike non-dissolvable bridge plugs, thereby ensuring better oil and gas quality.

- Energy Consumption Reduction: The automatic dissolution process reduces the need for equipment and manpower, consequently lowering the energy consumption and greenhouse gas emissions of the entire extraction process.

- Resource Utilization Efficiency: The use of dissolvable magnesium alloy enhances material utilization efficiency, as they eventually transform into useful substances or safely integrate into the environment rather than becoming difficult-to-handle waste.

Conclusion

Dissolvable magnesium alloy frac balls hold significant value in oil and gas extraction. They not only improve the efficiency and effectiveness of fracturing operations but also mitigate environmental impact through their controllable dissolution properties and anti-corrosion protection. By further optimizing material composition and manufacturing processes, dissolvable magnesium alloy tools will continue to enhance the sustainability and productivity of oil and gas extraction operations.