Dissolvable Magnesium Alloy – HH Series

- Dissolvable alloy bars are essential materials that have been formulated to provide high corrosion rates in a controlled manner. This material is widely used in construction and manufacturing.

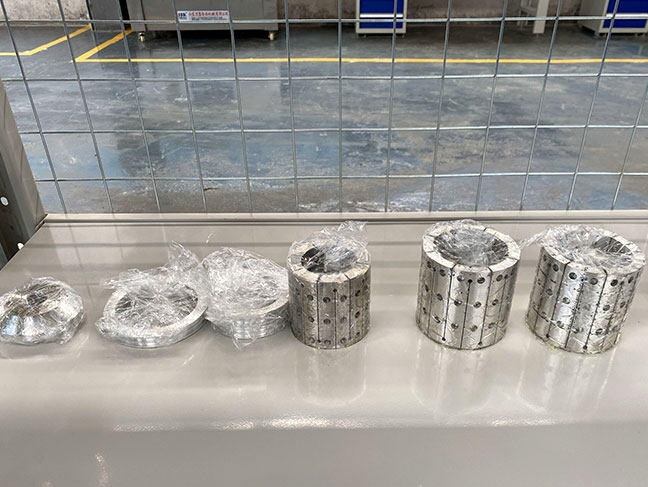

- It can be processed into dissolvable frac balls, dissolvable bridge plugs, dissolvable screws, magnesium alloy profiles and so on.

Share to

Manufacturing and Technological Advantages

The company project covers an area of 41,000 square meters, with a total investment of about 200 million yuan. In 2019, it will purchase and install a 4500-ton magnesium alloy special double-action extrusion line and its special machining and heat treatment equipment. It has rare earth magnesium master alloys, magnesium alloy smelting, die-casting, Semi-continuous casting rods, thin strip continuous casting, extrusion, rolling and stamping complete sets of R&D equipment and advanced material analysis and testing instruments; annual output of 200,000 pieces of soluble magnesium alloy bars, medium and large magnesium alloy products and special products 6000 tons. At the same time, the development of magnesium alloy bridge plugs and follow-up products and the construction of testing centers will be carried out simultaneously, with advanced product technology, strong feasibility, high technological content, and independent innovation construction.

Technical Achievements

The dissolvable frac plug currently used on the market is made of dissolvable metal & dissolvable rubber. Because the structure adopts the structure of the conventional bridge plug or packer, the parts are still numerous and the cost is high; and as the sealing part of the soluble bridge plug, the material is usually polymer elastomer, in order to make it soluble or aging, Adjust the formula to make it soluble in a certain period of time under the action of temperature or light. However, such elastic materials have great technical hidden dangers and construction risks in actual use.

The original mechanical performance must be strictly controlled in the storage environment after production, which leads to higher equipment management costs for construction operations in the field. If the storage time is too long, there is no effective evaluation and judgment on the product performance and quality.

Based on the three important indicators of soluble bridge plug temperature resistance, salinity solubility, and pressure resistance, the all-metal soluble bridge plug and bridge plug test and evaluation equipment developed by our company can solve these problems.

As a gas resource associated and symbiotic with coal, coalbed methane mainly refers to the hydrocarbon gas stored in coal seams, with methane as the main component, which is unconventional natural gas. Because CBM wells are generally shallow and multi-layered. It is very important to select suitable fracturing bridge plugs in layer fracturing for high-quality, low-cost, and fast completion of CBM well completion operations. The Wudu series A-type soluble fracturing bridge plugs produced by our company can adapt to a series of CBM service conditions such as low well temperature, low salinity, low well depth, and low pressure.

Application

| Grade | Max. Tensile Strength (Mpa) | Max. Pressure Strength (Mpa) | Yield Strength (Mpa) | Shear Strength (Mpa) | Elongation (%) | Elasticity Modulus (GPa) | Hardness (HB) | Testing Conditions | Dissolution Rate mg/(cm2*hr) | Dissolution Rate mm/hr | Density (g/cm3) | Sample Rod Size | |

| Temp. (℃ ) | Concentration of CL | ||||||||||||

|

HH-006 | 380 | 430 | 260 | 140 | >3 | 44.8 | >80 | 93 | 3% | 50-70 | 0.56 | 1.83 | Φ110×1000 |

| 380 | 430 | 260 | 140 | >3 | 44.8 | >80 | 93 | 1% | 20-35 | 0.35 | 1.83 | Φ110×1000 | |

| 240 |

| 180 |

| 26 |

|

| 150 |

|

|

|

| Φ90 | |

|

HH-006A | 320 | 366 | 240 | 162 | >6 | 44.8 | >75 | 93 | 3% | 50-70 | 0.56 | 1.83 | Φ70×1000 |

| 320 | 366 | 240 | 162 | >6 | 44.8 | >75 | 93 | 1% | 20-30 | 0.35 | 1.83 | Φ70×1000 | |

|

HH-008(012) | 410 | 486 | 290 | 197 | >5 | 45 | >100 | 93 | 3% | 40-55 | 0.46 | 1.94 | Φ110×1000 |

| 410 | 486 | 290 | 197 | >5 | 45 | >100 | 93 | 1% | 15-25 | 0.3 | 1.94 | Φ110×1000 | |

| 310 |

| 260 |

| 12 |

|

| 250 |

|

|

|

| Φ90 | |

|

HH-008A | 410 | 486 | 290 | 197 | >5 | 45 | >100 | 93 | 3% | 60-80 | 0.68 | 1.94 | Φ110×1000 |

| 410 | 486 | 290 | 197 | >5 | 45 | >100 | 93 | 1% | 35-50 | 0.42 | 1.94 | Φ110×1000 | |

|

HH-008B | 350 | 408 | 240 | 176 | >7 | 44.8 | >85 | 93 | 3% | 30-45 | 0.43 | 1.93 | Φ110×1000 |

| 350 | 408 | 240 | 176 | >7 | 44.8 | >85 | 93 | 1% | 15-25 | 0.25 | 1.93 | Φ110×1000 | |

| HH-010 | 200 | 325 | 130 | 99 | 24 | 44.3 | ≥40 | 93 | 3% | 20-30 | 0.12 | 1.8 | Φ110×1000 |

|

HH-011 | 410 | 486 | 300 | 197 | >4.5 | 44.8 | >100 | 93 | 3% | 20-35 | 0.28 | 1.93 | Φ110×1000 |

| 410 | 486 | 300 | 197 | >4.5 | 44.8 | >100 | 93 | 1% | 8-15 | 0.17 | 1.93 | Φ110×1000 | |

|

HH-016 | 280 | 350 | 190 | 127 | 13 | 44.8 | >60 | 93 | 3% | 40-55 | 0.46 | 1.8 | Φ110×1000 |

| 280 | 350 | 190 | 127 | 13 | 44.8 | >60 | 93 | 1% | 15-25 | 0.25 | 1.8 | Φ110×1000 | |

|

HH-017 | 210 | 352 | 150 | 99 | 18 | 44.8 | >60 | 93 | 3% | 40-55 | 0.48 | 1.8 | Φ110×1000 |

| 210 | 352 | 150 | 99 | 18 | 44.8 | >60 | 93 | 1% | 15-25 | 0.19 | 1.8 | Φ110×1000 | |

|

HH-017K | 235 | 352 | 170 | 120 | 15 | 44.8 | >60 | 93 | 3% | 100-130 | 0.75 | 1.81 | Φ110×1000 |

| 235 | 352 | 170 | 120 | 15 | 44.8 | >60 | 93 | 1% | 50-70 | 0.45 | 1.81 | Φ110×1000 | |

| HH-018 | 230 | 362 | 170 | 130 | 12 | 44.4 | ≥45 | 50 | 0.84% | 35-50 | 0.42 | 1.82 | Φ110×1000 |

|

HH-019 | 235 | 352 | 170 | 120 | 7 | 44.5 | >55 | 93 | 3% | 160-190 | 0.86 | 1.8 | Φ110×1000 |

| 235 | 352 | 170 | 120 | 7 | 44.5 | >55 | 45 | 0.10% | 20-40 | 0.15 | 1.8 | Φ110×1000 | |

| HH-021 | 305 | 415 | 220 | 140 | >3 | 44.5 | >65 | 43 | 0.05% | 80-100 | 0.81 | 1.94 | Φ110×1000 |

| HH-022 | 305 | 415 | 220 | 155 | >4.5 | 44.8 | >80 | 43 | 0.05% | 45-60 | 0.45 | 1.94 | Φ110×1000 |

| HH-023 | 275 | 385 | 180 | 140 | 8 | 44.5 | >65 | 43 | 0.05% | 20-35 | 0.27 | 1.93 | Φ28×1000 |

| HH-024 | 280 | 415 | 240 | 145 | >4.5 | 44.8 | >70 | 43 | 0.05% | 45-65 | 0.46 | 1.83 | Φ60×1000 |

| HH-808 | 370 | 486 | 262 | 197 | >3.5 | 44.8 | >100 | 50 | 0.84% | 40-60 | 0.44 | 2.16 | Φ110×1000 |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————