Dissolvable Frac Plugs vs. Dissolvable Bridge Plugs: How to Choose the Right One

In modern petroleum engineering, technologies such as dissolvable frac plugs and dissolvable bridge plugs play critical roles in optimizing wellbore isolation during hydraulic fracturing operations. Both tools aim to enhance the efficiency and economics of fracturing operations by providing temporary isolation of different wellbore sections. This isolation ensures that fracturing fluid is directed to the intended zones for maximum reservoir stimulation, thereby improving hydrocarbon recovery. The goal of this article is to compare the two downhole tools in detail, focusing on the differences of their construction, dissolution mechanisms, operational efficiency, and practical applications, to provide a clearer understanding of their relative merits in various scenarios, and how to choose the right one.

What are Dissolvable Frac Plugs and Dissolvable Bridge Plugs?

1. Definitions and Functions

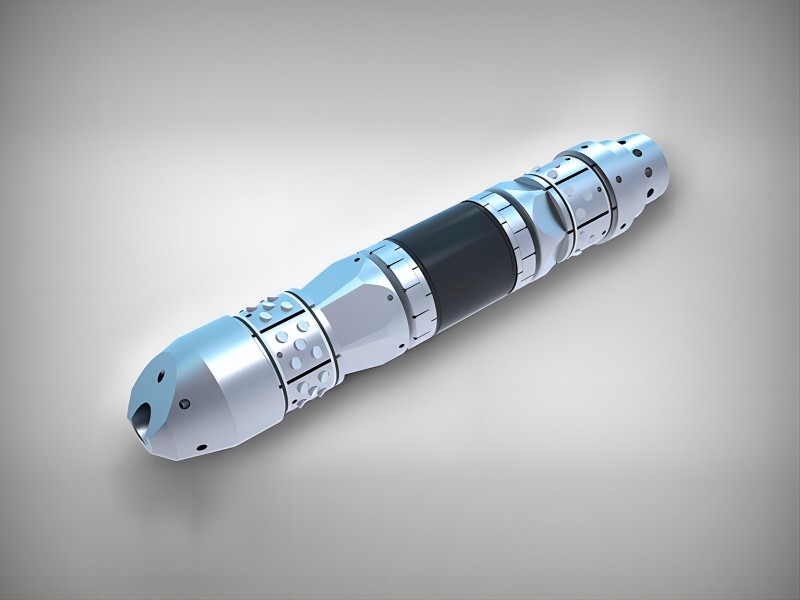

- Dissolvable Frac Plugs: These are temporary devices placed in a wellbore to isolate different stages or zones during hydraulic fracturing. Dissolvable frac plugs are used primarily in multi-stage fracturing, allowing operators to focus fracturing fluid and pressure on the desired intervals. Once their purpose is fulfilled, the plugs dissolve, leaving the wellbore free of obstructions.

- Dissolvable Bridge Plugs: Similar in function to frac plugs, dissolvable bridge plugs also isolate wellbore sections, but they often serve broader purposes. In addition to zone isolation, bridge plugs can also act as barriers to protect wellbore components like casing or liners. Like frac plugs, they are designed to dissolve after use, eliminating the need for manual retrieval.

Both tools are engineered for efficient zone isolation and the subsequent reopening of the wellbore. However, their specific roles and functionalities vary depending on operational goals, wellbore conditions, and the complexity of the fracturing job.

2. Working Principles

The operational workflow of dissolvable frac plugs and dissolvable bridge plugs shares similarities, with some distinctions in design and application:

- Dissolvable Frac Plugs: These plugs are typically run into the wellbore on a wireline or coiled tubing and set in place at predetermined depths. They seal the wellbore and enable fracturing fluid to be pumped into specific zones. Once the fracturing operation is complete, the frac plug dissolves under the influence of downhole conditions (such as temperature, pressure, and fluid composition).

- Dissolvable Bridge Plugs: Bridge plugs function similarly, but their use extends beyond hydraulic fracturing. They are also employed to seal off damaged or non-producing sections of the well or provide temporary barriers during workover operations. After performing their function, the bridge plugs dissolve, restoring the integrity of the wellbore.

Both tools rely on specific materials and mechanisms for their dissolution, which is crucial to their operational efficiency and post-use clearance.

Key Differences Between Dissolvable Frac Plugs and Bridge Plugs

Understanding the distinctions between these two types of dissolvable plugs can help engineers make informed decisions during the planning and execution of fracturing jobs. The following table outlines the key differences, applications, and technical considerations associated with each type of plug:

| Criteria | Dissolvable Frac Plugs | Dissolvable Bridge Plugs |

| Primary Uses | Used for temporary isolation during hydraulic fracturing operations in horizontal or complex wells. | Used for segmented fracturing, isolation, and testing operations in oil and gas wells. |

| Enables precise control of fracturing fluid injection to optimize performance. | Provides long-term sealing for extended periods of isolation. | |

| Structural Characteristics | Generally has a simple structure made from soluble materials. | Features a more complex structure with multiple components, including the body and rubber sleeves. |

| Designed for quick deployment and dissolution under specific conditions. | Provides stability and robust sealing capabilities within the wellbore. | |

| Dissolution Mechanisms | Relies on the chemical action of wellbore fluids for dissolution. | Also relies on chemical action of wellbore fluids for dissolution. |

| Designed to dissolve effectively, allowing for the efficient flow of fracturing fluids. | Focuses on maintaining long-term sealing and pressure retention during operations. | |

| Application Scenarios | Ideal for situations where precise control over fracturing fluid injection is required. | Suitable for scenarios that require long-term isolation of oil and gas formations, such as in horizontal and multilateral wells. |

| Especially beneficial in complex well configurations. | Ensures pressure integrity during fracturing. | |

| Technical Challenges | Ensuring proper timing and location for dissolution is crucial. | Providing reliable sealing during fracturing operations is a key challenge. |

| Requires careful planning to optimize the effectiveness of fracturing operations. | Ensures complete dissolution after the work is completed, adding complexity to design and application. |

How to Choose the Right Dissolvable Plugs

Selecting the appropriate dissolvable plugs—either dissolvable frac plugs or dissolvable bridge plugs—is critical to the success of hydraulic fracturing operations. The choice depends on various factors related to well conditions, operational requirements, and desired outcomes. Here are some key considerations to guide your decision:

1. Operational Objectives:

- If the primary goal is to achieve temporary isolation for fracturing fluid injection in horizontal or complex well sections, dissolvable frac plugs are the better choice. Their straightforward design allows for precise control and quick deployment.

- Conversely, if the objective is to provide long-term sealing for oil and gas formations, especially in horizontal and multilateral wells, dissolvable bridge plugs are more suitable. They are designed to maintain pressure integrity during extended isolation periods.

2. Well Characteristics:

- Evaluate the complexity of the wellbore. For wells that require accurate control over fracturing fluid placement, dissolvable frac plugs are advantageous.

- In scenarios where the well features multilateral branches or needs extended pressure maintenance, dissolvable bridge plugs provide the stability and sealing performance required.

3. Dissolution Requirements:

- Consider the timing and conditions under which the plugs need to dissolve. If the operational strategy requires dissolution at a specific time and location, focus on dissolvable frac plugs, which are designed for quick and effective performance.

- For operations where long-term sealing and subsequent dissolution are essential, opt for dissolvable bridge plugs. Their design prioritizes reliability during the fracturing process and ensures complete dissolution post-operations.

4. Technical Challenges:

- Assess the technical challenges specific to each plug type. If ensuring dissolution at the right time and location is critical, dissolvable frac plugs may present fewer complications.

- If the emphasis is on providing reliable sealing throughout the fracturing operations while ensuring complete dissolution afterward, dissolvable bridge plugs will be the better option, despite the added complexity in their application.

Ultimately, the choice between dissolvable frac plugs and dissolvable bridge plugs should be guided by the specific requirements of the hydraulic fracturing operation. By carefully considering the operational objectives, well characteristics, dissolution needs, and potential technical challenges, operators can select the most appropriate plugging solution to enhance the efficiency and effectiveness of their fracturing efforts.