Dissolvable Frac Plugs: A Game-Changer in Oil and Gas Well Fracturing

The success of oil and gas well fracturing hinges on creating temporary pathways within the wellbore to facilitate the injection of fracturing fluids. These fluids fracture the rock formation, enhancing its permeability and ultimately increasing hydrocarbon production. Traditionally, specialized plugs were used to isolate specific zones within the wellbore during this multi-stage process. However, their removal after fracturing required additional drilling operations, adding time, cost, and complexity. Dissolvable frac plugs have emerged as a revolutionary solution, offering significant advantages by eliminating the need for mechanical removal.

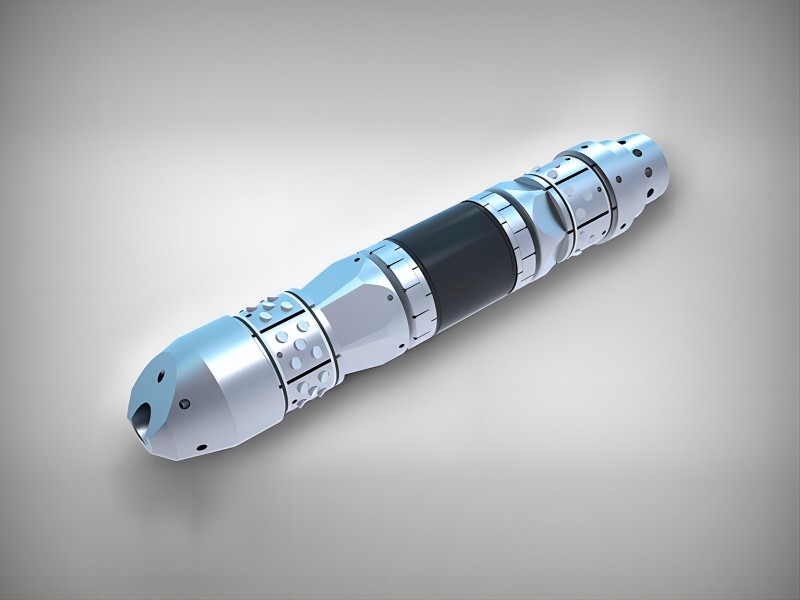

Technical Characteristics of Dissolvable Frac Plugs

Dissolvable frac plugs are designed to dissolve under specific conditions, usually by adding a specific chemical to the frac fluid or under certain temperature or pressure conditions. This feature allows dissolvable frac plugs to disappear automatically after fracturing, eliminating the need to manually remove traditional frac plugs by drilling and milling, and reducing the potential risks and costs associated with removing frac plugs.

Working Principle of Dissolvable Frac Plugs

Dissolvable frac plugs are specially designed tools deployed downhole during fracturing operations. They function by creating temporary isolation zones within the wellbore, allowing for targeted fracturing of specific intervals. Here’s a closer look at their structure and operation:

1. Structural Design: A dissolvable frac plug typically consists of three key components:

- Body: The main body of the plug is manufactured from a dissolvable material, often a magnesium-based alloy or other compounds engineered to dissolve under specific downhole conditions.

- Slips: These expandable mechanisms anchor the plug firmly within the wellbore casing. They are activated by a setting tool to create a tight seal.

- Sleeve: The sleeve, usually made from degradable rubber, provides an additional layer of sealing between the plug body and the wellbore wall. It’s designed to degrade under downhole conditions after the fracturing operation.

2. Operation Process: During the fracturing process, the dissolvable frac plug is delivered downhole through a cable or coiled tubing system and positioned at the desired location within the wellbore. A setting tool activates the slips, causing them to expand and press the sleeve against the casing wall, forming a secure seal.

Once the fracturing operation for that specific zone is complete, the wellbore fluid composition changes. This triggers the dissolution process. The chosen dissolvable materials in the plug’s body and sleeve react with the specific chemicals or a combination of temperature and pressure in the fracturing fluid, causing them to gradually dissolve or break down. This allows the wellbore to become fully open for production testing and ultimately oil and gas flow.

3. Dissolution Process Control: The dissolution rate of a dissolvable frac plug can be controlled by manipulating various downhole conditions. Factors such as temperature, pressure, and the specific chemical composition of the fracturing fluid can be adjusted to achieve the desired rate of dissolution. For instance, altering the concentration of chloride ions in the fluid or introducing specific additives can influence how quickly the plug breaks down.

Suitability of Dissolvable Frac Plugs for Different Oilfield Types

The unique ability of dissolvable frac plugs to dissolve under controlled downhole conditions makes them a highly versatile tool for good stimulation across various oilfield types. Let’s delve deeper into how their characteristics benefit specific reservoir challenges:

1. Tight Oil and Gas Fields

- Challenge: Tight oil and gas formations have inherently low permeability, meaning fluids like oil and gas have difficulty flowing through the rock. This significantly restricts hydrocarbon production.

- Solution: Fracturing is an essential technique for stimulating production in tight reservoirs. It involves creating fractures in the rock formation by pumping a high-pressure fluid at a controlled rate. Proppant materials are then placed within these fractures to keep them open, allowing oil and gas to flow more freely. However, traditional fracturing plugs used to isolate zones during multi-stage fracturing operations require milling to remove after the process.

- Dissolvable Frac Plug Advantage: One of the biggest advantages of dissolvable frac plugs in tight oil and gas fields is their ability to ensure complete wellbore cleanup after fracturing. Unlike traditional plugs that can leave behind debris after milling, dissolvable frac plugs completely dissolve, eliminating any obstruction in the wellbore. This allows for unimpeded flow of oil and gas from the newly created fractures, maximizing hydrocarbon recovery rates.

2. Shale Gas Fields

- Challenge: Shale gas reservoirs are characterized by low porosity (amount of empty space in the rock) and permeability. Efficient production relies on creating a complex network of fractures to enhance hydrocarbon flow from these formations.

- Solution: Horizontal wells with long laterals are commonly used to maximize the wellbore’s contact area with the shale formation. Multi-stage fracturing is then employed to create a network of fractures along the entire wellbore.

- Dissolvable Frac Plug Advantage: Dissolvable frac plugs play a crucial role in successful shale gas development in two key ways:

- Preserving Wellbore Integrity: Traditional frac plugs require milling for removal, which can damage the delicate network of fractures created during fracturing. Dissolvable frac plugs eliminate this risk by dissolving on their own, protecting the wellbore integrity and the crucial fracture network for optimal shale gas production.

- Facilitating Efficient Multi-Stage Fracturing: As mentioned earlier, horizontal wells with long laterals are preferred for shale gas development. Dissolvable frac plugs enable the efficient isolation and fracturing of multiple zones along the extended wellbore in a single operation. This eliminates the need for multiple runs of setting and retrieving traditional frac plugs, significantly optimizing stimulation effectiveness and ultimately, good productivity.

3. Offshore Oil and Gas Fields

- Challenge: Offshore oil and gas exploration and production present unique challenges due to complex logistics and significantly higher operational costs compared to onshore operations. Every additional well intervention adds substantial time and expense to the project.

- Solution: Dissolvable frac plugs offer significant advantages in these environments by streamlining the fracturing process.

- Dissolvable Frac Plug Advantage: By eliminating the need for a separate milling run to remove traditional frac plugs, dissolvable frac plugs significantly reduce operational complexity. This translates to fewer well interventions, leading to substantial cost savings in offshore settings. Additionally, the reduced operational time translates to improved economic efficiency of offshore oil and gas projects. Furthermore, by minimizing wellbore intervention needs, dissolvable frac plugs can help reduce the environmental footprint of offshore operations by lowering the risk of spills and emissions associated with additional interventions.

Dissolvable Frac Plugs

Conclusion

Dissolvable frac plugs have revolutionized the fracturing process, offering significant advantages over traditional fracturing techniques. Their ability to create temporary isolation zones, coupled with their self-dissolving nature, streamlines operations, reduces costs and minimizes wellbore intervention risks. As research and development efforts continue, dissolvable frac plugs are expected to become even more sophisticated, controllable, and environmentally friendly. This will solidify their position as a critical tool for maximizing wellbore productivity and optimizing oil and gas recovery across various reservoir types.