Dissolvable Frac Balls: Revolutionizing Fracture Stimulation in the Oil and Gas Industry

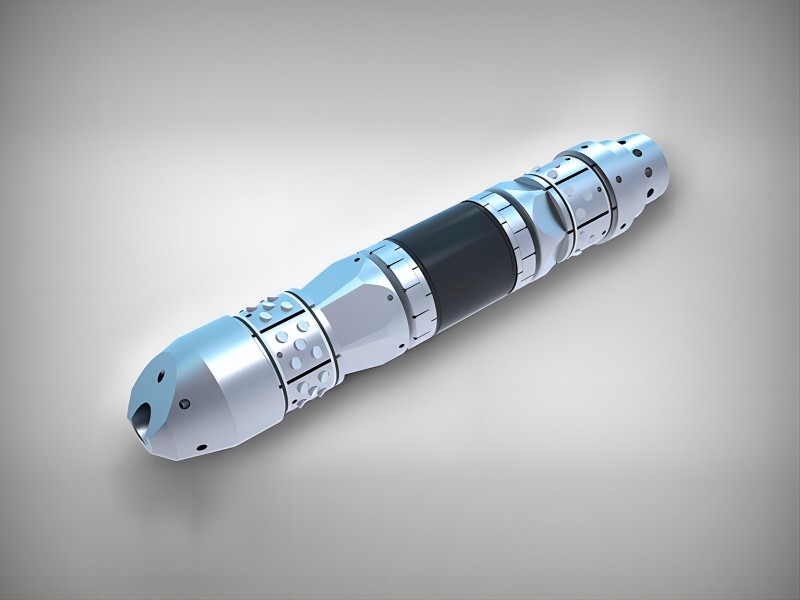

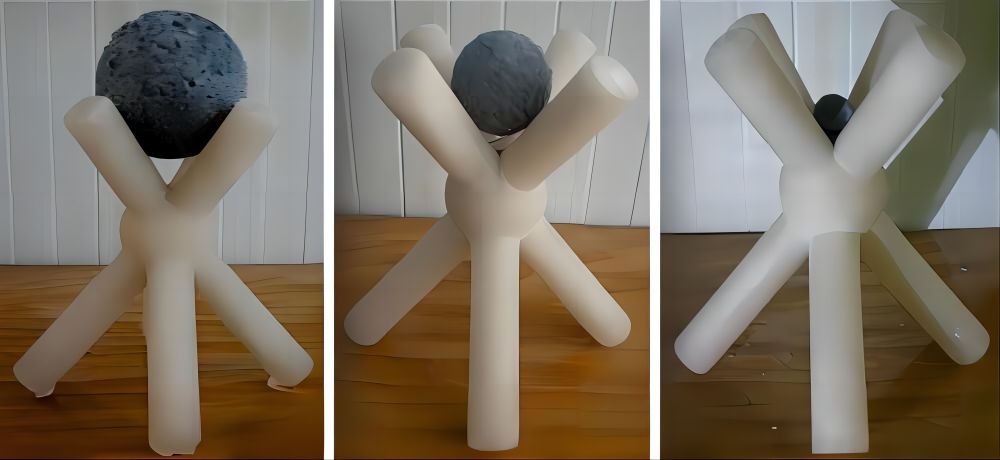

In the dynamic world of oil and gas exploration, maximizing wellbore efficiency and minimizing environmental impact are paramount concerns. Frac balls, small, retrievable spheres pumped downhole during hydraulic fracturing operations, play a crucial role in isolating specific formation intervals for targeted stimulation. However, traditional frac balls, typically composed of ceramic or metal, require retrieval after stimulation, adding significant cost and environmental burden.

Wingoil, a leading innovator in well-completion solutions, has pioneered a proprietary dissolvable frac ball material specifically engineered to eliminate retrieval operations. This article delves into the intricate details of Wingoil’s dissolvable frac balls, highlighting their material composition, key advantages, diverse applications, and compelling reasons for choosing them over traditional alternatives.

Beyond Traditional Materials: Unveiling the Science of Dissolvable Frac Balls

Conventional frac balls, primarily comprised of ceramics or metals, necessitate post-operation retrieval procedures. This not only extends completion timelines and incurs significant cost burdens but also raises environmental concerns due to surface disposal challenges. Wingoil’s revolutionary dissolvable frac balls, meticulously engineered from specialized materials, offer a paradigm shift by dissolving completely within the downhole environment. Let’s delve deeper into the science behind these materials and their key advantages:

1. Precise Dissolution Control

- Tailored Degradation Profiles: Wingoil employs a meticulous material selection and formulation process to ensure the dissolution rate of each frac ball precisely matches the specific downhole environment. This calibrated approach guarantees complete degradation within a predetermined timeframe, aligning with the fracturing schedule and eliminating the need for retrieval operations.

- Advanced Kinetic Modeling: Wingoil leverages advanced kinetic modeling techniques to predict and control the dissolution behavior of its frac ball materials under varying downhole conditions. This ensures optimal performance and prevents premature or delayed degradation, safeguarding both operational efficiency and environmental sustainability.

- Downhole Monitoring and Optimization: Wingoil offers advanced downhole monitoring tools and data analysis capabilities to track the dissolution progress of frac balls in real time. This allows for dynamic adjustments to fracturing schedules or fluid compositions, further optimizing the dissolution process and maximizing operational effectiveness.

2. Expansive Chemical Compatibility

- Broad Spectrum Fluid Compatibility: Wingoil’s dissolvable frac balls are meticulously formulated to exhibit exceptional compatibility with a wide range of fracturing fluids commonly utilized in the industry. This includes slickwater, hybrid, and crosslinked systems, encompassing a diverse spectrum of chemical compositions and viscosities.

- Eliminating Compatibility Risks: By ensuring broad-spectrum compatibility, Wingoil eliminates the risk of adverse interactions between frac balls and fracturing fluids, which can lead to performance degradation, formation damage, and operational disruptions. This versatility allows for seamless integration into existing fracturing strategies and broader applicability across diverse formations.

- Customized Material Formulations: For highly specific or challenging downhole environments, Wingoil offers the ability to customize the material composition of its frac balls to achieve optimal compatibility with the chosen fracturing fluid system. This tailored approach ensures maximized performance and reliability even in unconventional scenarios.

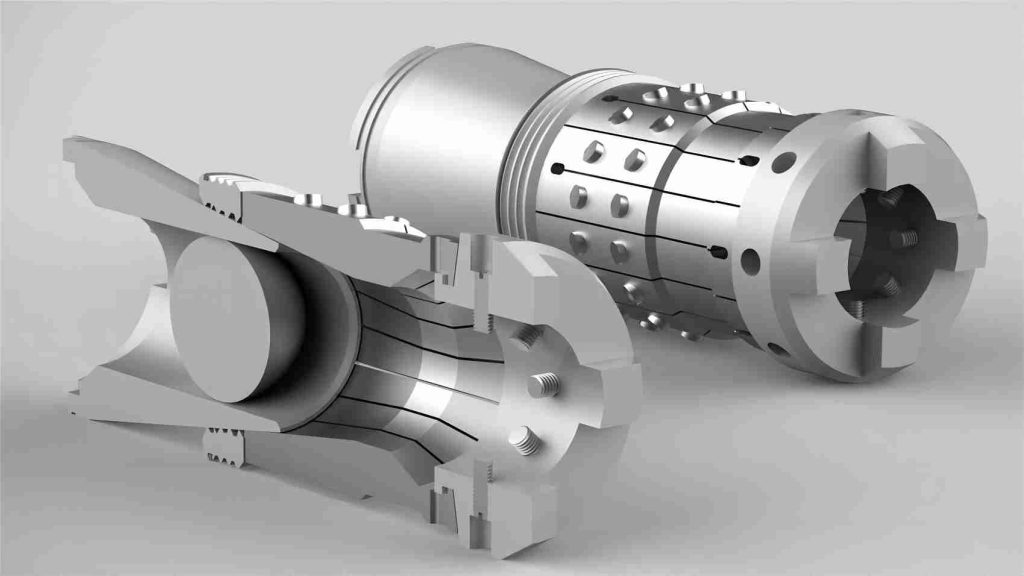

3. Superior Mechanical Integrity

- High-Strength Materials: Despite their dissolvable nature, Wingoil’s frac balls are meticulously engineered from high-strength materials capable of withstanding the extreme pressures and temperatures encountered during fracturing operations. This ensures they maintain their structural integrity throughout the entire fracturing process, preventing premature degradation or failure.

- Rigorous Testing Procedures: Each frac ball undergoes rigorous testing procedures exceeding industry standards to evaluate its mechanical properties under simulated downhole conditions. This comprehensive testing regime ensures the reliability and performance of Wingoil’s frac balls in even the most demanding environments.

- Computational Modeling and Optimization: Wingoil utilizes advanced computational modeling techniques to optimize the mechanical design of its frac balls, ensuring they possess the necessary strength and integrity while minimizing material usage. This optimizes both performance and cost-effectiveness.

Exploration of Wingoil’s Dissolvable Frac Ball Benefits

Wingoil’s dissolvable frac balls deviate from conventional approaches, unlocking a plethora of operational and environmental advantages that resonate deeply within the oil and gas industry. Let’s delve into the specifics:

1. Streamlined Operations and Cost Optimization

- Elimination of Retrieval Operations: Traditional frac balls necessitate post-fracture retrieval, a time-intensive and expensive process involving specialized equipment and personnel. Wingoil’s dissolvable design bypasses this entirely, as the balls degrade downhole, eliminating retrieval costs and accelerating completion timelines. This translates to significant cost savings per well and expedites overall project execution.

- Reduced Operational Complexity: By removing the retrieval step, Wingoil’s solution simplifies the entire fracturing operation. This streamlined approach minimizes logistical requirements, reduces the number of personnel needed on-site, and mitigates potential complications associated with retrieval, leading to a smoother and more efficient completion process.

2. Environmental Footprint Minimization

- Elimination of Surface Disposal: Conventional frac balls require post-fracture retrieval and subsequent surface disposal, often in designated landfills. This raises environmental concerns and incurs additional costs associated with transportation and disposal fees. Wingoil’s dissolvable balls eliminate this issue entirely, as they degrade downhole into environmentally benign components, minimizing the surface footprint and aligning with evolving sustainability regulations.

- Reduced Freshwater Consumption: Retrieval operations often necessitate substantial freshwater volumes for cleaning and processing retrieved balls. Wingoil’s dissolvable technology eliminates this freshwater requirement, contributing to water conservation efforts in water-stressed regions and minimizing the overall environmental impact of fracturing operations.

3. Enhanced Completion Efficiency and Hydrocarbon Recovery

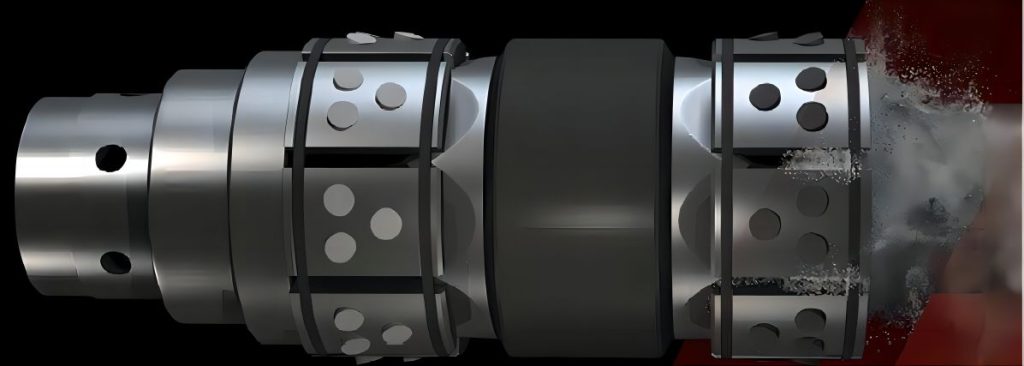

- Precise Stage Isolation: Dissolvable frac balls offer superior stage isolation compared to traditional retrievable balls. Their controlled dissolution profile ensures accurate isolation of individual fracture stages within the wellbore, preventing fluid communication between stages and directing fracturing energy precisely where needed. This leads to more targeted stimulation, improved reservoir contact, and ultimately, higher hydrocarbon recovery rates.

- Optimized Fracture Geometry: The precise stage isolation enabled by dissolvable frac balls allows for the creation of complex fracture geometries tailored to specific reservoir characteristics. This optimization enhances fracture conductivity and drainage area, leading to increased well productivity and overall hydrocarbon recovery potential.

4. Enhanced Operational Safety and Reduced Downtime

- Elimination of Stuck Ball Risk: Traditional frac balls pose the inherent risk of getting lodged downhole, requiring costly and time-consuming intervention procedures. Wingoil’s dissolvable design eliminates this risk entirely, as the balls degrade predictably, ensuring smooth completion operations and preventing potential safety hazards associated with stuck ball scenarios.

- Reduced Downtime: The streamlined nature of dissolvable frac ball technology minimizes operational downtime compared to traditional methods. Elimination of retrieval eliminates potential delays associated with complications or equipment failures during retrieval, leading to faster completion times and improved operational efficiency.

By offering these tangible benefits, Wingoil’s dissolvable frac ball technology sets a new standard for efficiency, sustainability, and safety within the fracturing industry. It empowers operators to achieve their production goals while minimizing environmental impact and adhering to evolving regulations, paving the way for a more responsible and sustainable future for the oil and gas sector.

A Multifaceted Application Landscape: Tailored Solutions for Diverse Downhole Challenges

Wingoil’s dissolvable frac ball technology transcends limitations by catering to a wide spectrum of oil and gas operations, encompassing diverse reservoir characteristics, wellbore geometries, and downhole conditions. Let’s explore this versatile applicability:

1. Adapting to Reservoir Heterogeneity

- Tight Oil and Gas Formations: Tight formations, characterized by low permeability, often require multi-stage fracturing for optimal hydrocarbon recovery. Wingoil’s frac balls facilitate precise isolation of individual fracture stages within these low-permeability environments, enabling targeted stimulation and maximizing production potential.

- Conventional Sandstone and Shale Plays: In conventional reservoirs with higher permeability, Wingoil’s frac balls offer advantages by ensuring efficient fracture diversion and preventing unwanted communication between stages, ultimately leading to improved sweep efficiency and hydrocarbon recovery.

2. Flexibility Across Wellbore Geometries

- Horizontal Wells: Horizontal well completions often necessitate the isolation of numerous fracture stages along extended wellbores. Wingoil’s frac balls enable this efficiently, with controlled dissolution ensuring stage isolation without compromising wellbore integrity or hindering production flow.

- Vertical Wells: Traditional vertical well completions can also benefit from Wingoil’s technology. The precise isolation capability offered by dissolvable frac balls allows for targeted stimulation of specific zones within the vertical wellbore, optimizing production and minimizing unwanted stimulation in less productive intervals.

3. Conquering Downhole Extremes

- High-Pressure Environments: In deep formations with elevated pressures, conventional frac balls might experience structural limitations. Wingoil’s dissolvable frac balls are meticulously engineered to withstand extreme downhole pressure, ensuring reliable performance and stage isolation even in challenging environments.

- High-Temperature Environments: High-temperature formations pose additional challenges for fracturing operations. Wingoil’s frac balls are formulated with temperature-resistant materials, guaranteeing their integrity and controlled dissolution even in geothermal reservoirs or formations requiring high-temperature fracturing fluids.

Why Choose Wingoil? A Fusion of Innovation, Quality, and Customer Centricity

In the dynamic and competitive fracturing technology landscape, Wingoil distinguishes itself through a steadfast commitment to three core pillars: unparalleled material expertise, stringent quality control, and comprehensive customer support, coupled with competitive pricing and reliable delivery. Let’s delve deeper into these differentiators:

1. Unrivaled Material Expertise

- Rigorous R&D: Wingoil dedicates significant resources to ongoing research and development, continuously innovating and refining its dissolvable frac ball materials. This translates to superior performance characteristics, including controlled and predictable dissolution rates, exceptional mechanical strength under downhole pressure and temperature, and broad compatibility with diverse fracturing fluids.

- Proprietary Material Formulations: Wingoil leverages its deep understanding of material science to develop proprietary formulations optimized for specific downhole environments and fracturing applications. This ensures optimal performance and reliability across various wellbore conditions, exceeding industry standards and exceeding competitor offerings.

2. Stringent Quality Control

- Multi-Stage Testing: Wingoil implements a rigorous multi-stage quality control program encompassing raw material inspection, manufacturing process monitoring, and post-production performance testing. This ensures consistent quality and adherence to the highest industry standards, minimizing the risk of defects and maximizing field reliability.

- Advanced Quality Management Systems: Wingoil employs sophisticated quality management systems, incorporating statistical process control and continuous improvement methodologies. This ensures product consistency, traceability, and compliance with relevant regulatory requirements.

3. Comprehensive Customer Support

- Dedicated Technical Team: Wingoil boasts a team of experienced engineers and technical specialists with in-depth knowledge of fracturing operations and dissolvable frac ball technology. This team provides comprehensive support to clients throughout the project lifecycle, from initial planning and design to execution and troubleshooting.

- Tailored Solutions: Wingoil recognizes that each project presents unique challenges and requirements. Its team actively collaborates with clients to develop customized solutions that perfectly align with their specific needs and wellbore characteristics, ensuring optimal performance and maximizing project success.

4. Competitive Pricing and Reliable Delivery

- Cost-Effective Solutions: Wingoil understands the importance of cost optimization in today’s competitive environment. It offers its dissolvable frac balls at competitive prices, ensuring affordability and value for its clients.

- Streamlined Supply Chain: Wingoil has established a robust and efficient supply chain network, guaranteeing timely and reliable delivery of its products to meet project deadlines and minimize operational disruptions.

By weaving together these key differentiators, Wingoil creates a compelling value proposition for operators seeking to optimize their fracturing operations. Its commitment to innovation, quality, and customer support, coupled with competitive pricing and reliable delivery, positions Wingoil as a trusted partner for successful and sustainable fracturing projects.

Conclusion

Wingoil’s dissolvable frac ball technology represents a paradigm shift in the oil and gas industry. By offering a solution that balances operational efficiency, environmental responsibility, and safety, Wingoil empowers operators to achieve their production goals sustainably. As the industry evolves towards a more responsible and efficient future, Wingoil stands ready to be a valued partner, driving innovation and progress through its revolutionary dissolvable frac ball technology.