Disintegrating Frac Plug Coiled Tubing Downhole Tools

- Conventional mechanical plugs can become obstacles, requiring costly and time-consuming mill-out or wireline operations, leading to significant delays and increased operational risks.

- Enter the disintegrating frac plug, a cutting-edge solution engineered with advanced materials that dissolve in selected completion fluids. These plugs are designed to function under high pressure and temperature, providing robust downhole isolation during fracturing processes. Once the desired production stage is complete, the plugs seamlessly disintegrate, leaving no residual materials to hinder the flow of oil or gas.

Share to

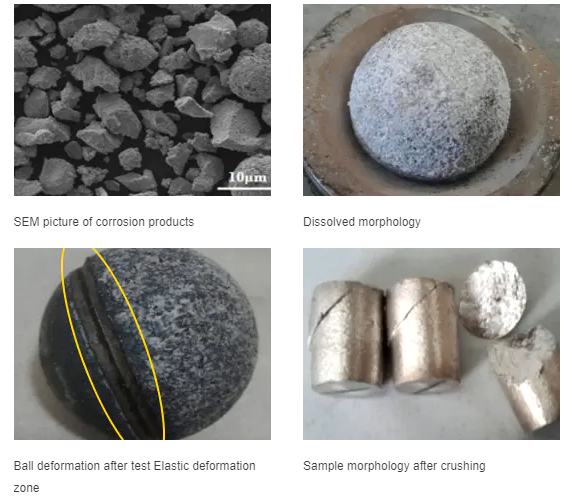

01-Self-made multi-strength soluble metal manufacturing, dissolution time on demand transformation

The main body of our company’s soluble bridge plugs is made of self-developed multi-strength soluble magnesium metal composite. After the core material composite application, the dissolution time of the whole machine is completely consistent, no residue, no toxicity, according to the on-site water quality and work. It is necessary to adjust the formula at any time to change the unique advantage of dissolution time.

- The modulus of elasticity is about 70~80 KN/m㎡.

- It can be used for sliding sleeves with a range of 1/10 in.

- Solved the problem of material strength stability at high temperatures.

- The maximum compressive strength of high temperature is adjustable from 550 to 650 MPa.

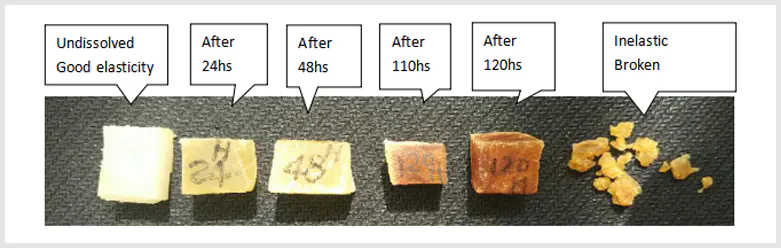

02-Self-developed high-strength degradable rubber cylinder for quick release of pluggin

The fully soluble bridge plug rubber cylinders are all made of self-developed high-strength degradable materials. Since the materials are uniquely produced by our company and have the advantages of effective control of degradation start-up time and degradation time, six temperature series products have been formed.

Partial sol-tube performance parameter table

| Type | RJ001 – A | RJ001 – B | RJ001 – C | RJ001 – D |

| Stable time (hrs) | 48 | 48 | 48 | 48 |

| Degradation time (days) | 15 | 15 | 15 | 15 |

| Working temperature (℃) | 60 to 80 | 80 to 100 | 100 to 120 | 120 to 150 |

03-Total solution and no residual fracturing bridge plug

Our company’s dissolvable bridge plug adopts unique high-strength disintegratable ceramic anchor teeth, the highest strength reaches 1250MPa, which can meet the reliable anchoring of high-strength casings such as P110 and P105. The stable period is more than 15 days, and the stable period is stable. After that, the anchor teeth can be automatically broken and dispersed into pieces smaller than 2mm according to the design parameters, thereby ensuring that the residual solid phase of the anchor teeth can be discharged with the production liquid, and become a true total solution and no residual fracturing bridge plug.

04-Special setting pressure design protection, effectively prevent mid-setting

The dissolvable bridge sikava adopts high-strength limit locking structure and integral hydraulic dispersion design to ensure that the tonnage of the setting is higher than 30KN (speed of 4000m/h state impact force), so that the tool can be pumped and down. Effectively prevent mid-sealing and ensure operation safety

05-Upper and lower two-way kava anchoring structure, effectively preventing the bridge plug from moving up during production

The bridge plug is anchored on the anchoring structure, and the upper and lower slips are bidirectionally anchored to the sleeve structure, so that the bridge plug is reliably locked in the position of the sleeve section after the setting, thereby preventing the bridge plug from being loosened by hydraulic shock and move up, resulting in blockage of the wellbore during production.

06-The overall diversion design prevents the sealing ball from moving up and blocking

In order to effectively ensure the flow of the solution and prevent the lower soluble ball from blocking the bridge plug production channel after moving up, the design adopts a multi-hole opening structure, and the diversion hole and the flow are designed at the position of the bridge plug cone, the mandrel and the lower joint. The tank has a total flow area larger than the inner passage to ensure smooth flow of the production and dissolution liquid channels.

07-Threaded quick-dissolving ring to ensure emergency handling when release errors

The bridge plug release ring is designed for threaded release joints. It uses a quick-dissolving material and uses a load-thread release structure that dissolves quickly in 2% of the salt solution for 36-54 hours to unlock the bridge release lever. When a release error occurs, the bridge plug can lock the error release by natural dissolution. At the same time, the structural design is designed with the soluble release joint load thread pull-pull as the main body, and no insoluble parts remain in the well after release.

08-Perfect exception handling technology to make application risk lowe

In the application process, the general bridge plugs often have special conditions such as abnormal setting, jamming, and sand-buried bridge plugs. According to the material characteristics, our products are equipped with acid fast solution and fast-dissolving and easy-drilling material structure. When the bridge plug cannot be dissolved according to the design and cannot be treated by the instant solution technology, it can quickly release the plug and restore the normal state of the wellbore. The rapid processing technology that is unique to the all-in-one bridge plug has been fully utilized.

| Model | Outer Diameter (mm) | Inner Diameter (mm) | Length (mm) | Operating Temperature (℃) | Pressure Difference (Mpa) | Casing Inner Diameter (mm) |

| WY453-110 | 110 | 40 | 680 | 120/150 | 70 | 118-124 |

| WY453-105 | 105 | 40 | 680 | 120/150 | 70 | 114-118 |

| WY453-95 | 95 | 30 | 680 | 120/150 | 60 | 114-115 |

| WY453-95 | 95 | 30 | 680 | 120/150 | 70 | 108-110 |

| WY453-85 | 85 | 22 | 650 | 120/150 | 60 | 114-115 |

| WY453-85 | 85 | 22 | 670 | 120/150 | 70 | 102-104 |

| WY45R92-70 | 92 | 30 | 595 | 40-150 | 70 | 100-110 |

| WY45R95-70 | 95 | 36 | 640 | 40-150 | 70 | 103-116 |

| WY45R102-70 | 102 | 40 | 595 | 40-150 | 70 | 110-122 |

| WY45R110-70 | 110 | 48 | 595 | 40-150 | 70 | 118-136 |

| Max. test pressure | 600 to 900 bar / 60 to 90MPa |

| Rated working pressure difference | 35/50/70MPa |

| Max. working temperature | 120, 150°C |

| Min. setting force | 100KN |

| Max. setting force | 140KN |

| Max. releasing force | 140KN |

| Weight | 6.1Kg |

| Medium | 0.5 to 2% KCL salt solution |

| Blocking period | 36 hours |

| Releasing dissolution time | 5 to 7 days |

| Complete dissolution time | 15 to 25 days |

| Setting and feeding method | Cable or hydraulic feed |

| Conditions suitable for wellbore | Vertical and horizontal wells without direct contact with acidic working environment |

| Setting tool model | Weatherford HST or AH, Baker Hughes E-4, NO.20, (Wingoil) WYSS-1, DWYSS-1 setting tool |

Mechanical Properties of Partially Soluble Metal Materials

| Type | KR001-A | KR001-B | KR001-C | KR001-D |

| Compressive strength (MPa) | 300 | 380 | 480 | 600 |

| Tensile strength (MPa) | 310 | 390 | 470 | 520 |

| Working temperature (℃) | 180 | 180 | 180 | 180 |

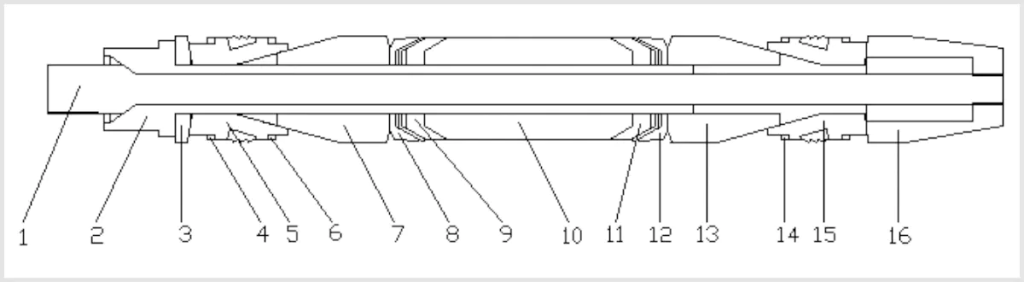

1-Back-off screw 2-Mandrel 3-Thrust ring 4-Shroud ring 5-Slip 6-Shroud ring

7-Upper cone 8-Support ring 9-Packer rubber A 10-Packer rubber B 11-Packer rubber B

12-Support ring 13-Support ring 14-Ring clamp 15-Slip 16-Thrust cylinder

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————