Characteristics

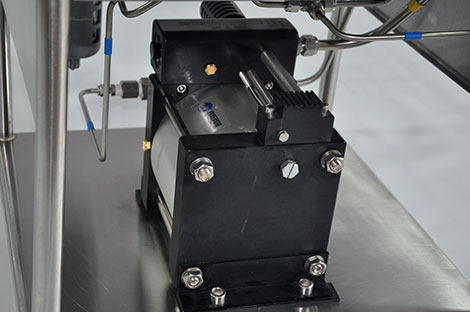

- Boosters’ operating principle is similar to a pressure intensifier. A large air piston is charged with low pressure (air piston (3)) and works on a small area with high pressure (hp piston (2)). The continuous operation is achieved by a pilot-operated 4/2 way valve (spool (4)). The spool leads the drive air alternately on the upper and bottom surfaces of the air piston.

- The spool is piloted through two 2/2 way valves (pilot valves (7)) which are mechanically actuated through the air piston in its end positions. The pilot valves charge and discharge the spool chamber. The hp piston supported by the check valves (inlet check valve and outlet check valve (1)) delivers the flow.

- The outlet pressure is directly related to the set air drive pressure. According to the formulas indicated in the table with technical features of the boosters, the static end pressure can be calculated. At this pressure, a force balance between the drive section and the CO2 section is achieved. The booster stalls when this end pressure is reached and does not consume any further air.

- A pressure drop at the high-pressure side or a pressure increase at the drive side starts the booster automatically until the force balance is achieved again. Additionally, the boosters can be switched on and off automatically through air pilot switches, contact gauges, or external control devices.

Specifications

- Leak test

- CO2 transfer

- CO2 recovery

- CO2 foaming

- Pressure test with CO2

- CO2-assisted injection molding

- Supply for isolating CO2 systems

- As a result of the wide range of models, it is possible to select the optimum booster for each application. Single-stage, double acting or two-stage boosters, or a combination of these models can be used to achieve different operating pressures and flow capacities.

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————