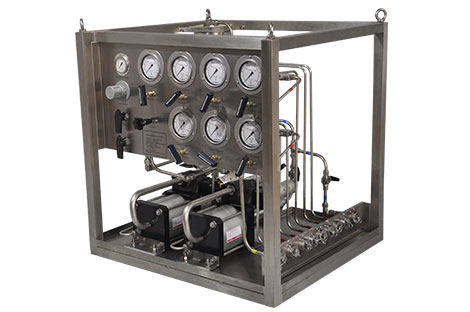

Chemical Injection Skid with Variable Output Pressure and Flow

- Chemical Injection Skid, is a piece of equipment designed to inject chemicals into a system at the required pressure of the system.

- WINGOIL chemical injection skid provides low-pressure compressed air as a booster power source a pressure to keep convenience and safety. This equipment is applicated in surface low pressure, and downhole high pressure.

Share to

Overview

Chemical injection skids are essential components in various industries, such as oil and gas, pharmaceuticals, water treatment, and manufacturing, where precise dosing of chemicals is critical for operational processes. One crucial advancement in chemical injection skid technology is the incorporation of variable output pressure and flow rate capabilities, which offers enhanced control and flexibility in chemical injection operations.

Feature

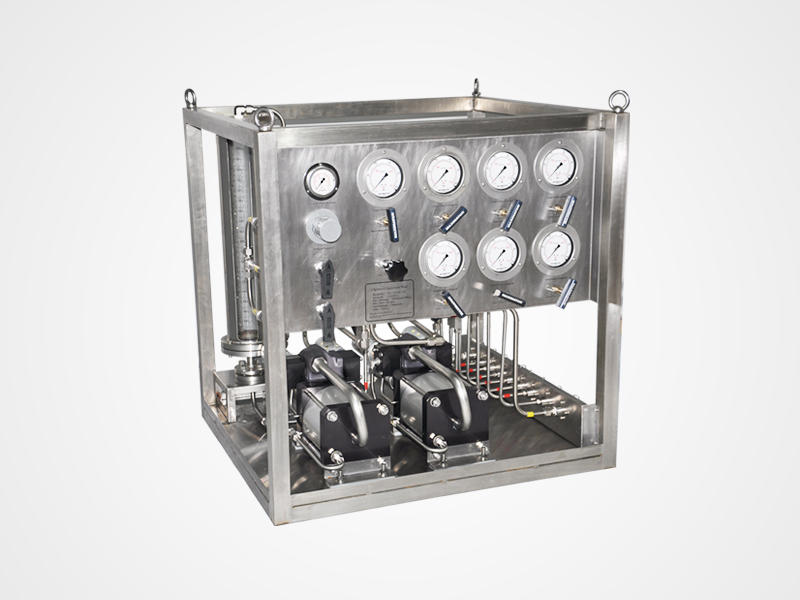

- With shockproof and dual scale display pressure gauge.

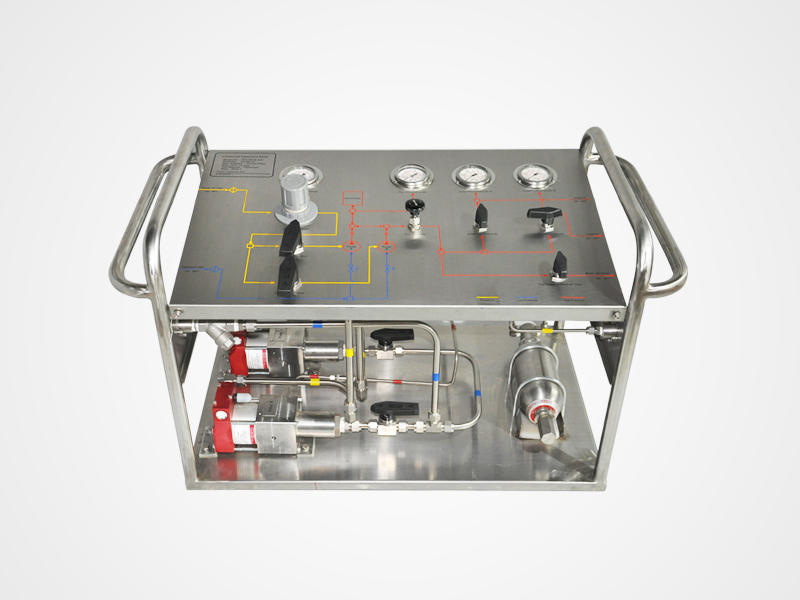

- Has operation schematic on the control panel, which is easy to observe and operate.

- Low-pressure compressed air as booster power source to keep convenience and safety.

- All components, piping and valves are made of 316s or 316L, which can prevent from corrosion effectively.

- Adopted pressure to be self-locked to adjust output pressure keeps constant in case of overshoot under air-driven pressure setting constant.

- Equipped with a glass column and high-precision flow control valve to meet the requirements of high flow rate chemical injection.The main -material are glass and 316s to meet the corrosion-proof requirements.

| Chemicals | Anti-frozen agent, viscosity reducer, blocking remover, biocide chemicals, oxygen scavenger, pour point disperant (PPD), anti-corrosion agent |

| Pressure | 0 to 2000 bar / 29000 PSI |

| Flow rate | 0 to 24L/min (Customizable) |

| Pressure accuracy | ±1%FS |

| Ambient temperature | -20℃ to 65℃ |

| Application | Surface low pressure, downhole high pressure |

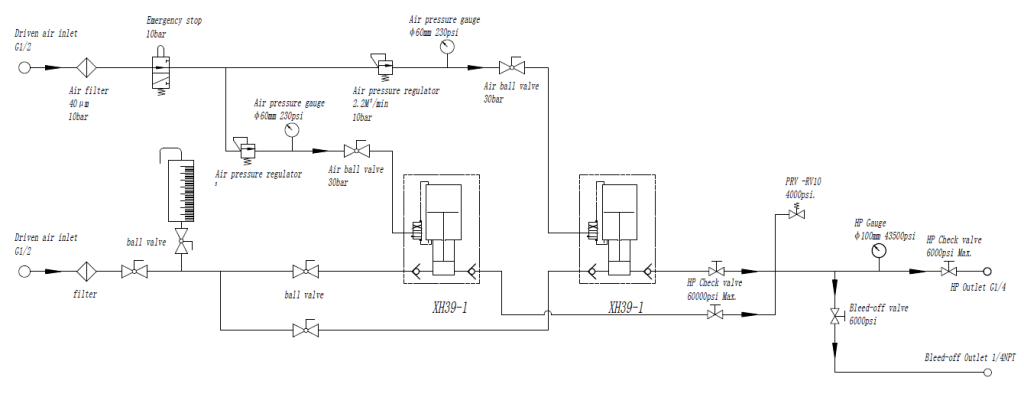

| Max. outlet pressure | 275 bar / 4,000 psi |

| Max. flow rate | 2.89 L/M |

| Driving air inlet | NPT1/2F |

| Fluid inlet | NPT1/2F |

| HP outlet | NPT1/4 |

| Bleed-off outlet | NPT1/4 |

| No. of HP outlets | 1 (available for more outlets) |

| Dimension | 700L*600W*550H (mm) |

| Weight | 66 kgs |

| Pneumatic pump | Two sets of pumps, one for working, the other for standby |

| Pump model | WYXH39-1 |

| Pressure ratio | 1:39 |

| Driven by | Compressed air |

| Driving air pressure | 100 psi |

Part List

| Pneumatic pump | S/S | 2 |

| Air-driven ball valve | S/S | 6 |

| Air regulator | Rubber & Alloy | 2 |

| Bulkhead union | S/S | 2 |

| HP bleed-off valve | S/S | 1 |

| Air filter | S/S | 1 |

| HP gauge | S/S | 1 |

| LP gauge | S/S | 2 |

| Check valve | S/S | 2 |

| Safety valve | S/S | 1 |

| Emergency stop | Copper | 1 |

| Metering | S/S | 1 |

| Metering valve | S/S | 1 |

| Y strainer | S/S | 1 |

| HP tubings | S/S | Meters |

| Connectors | S/S | Numbers |

| Frame | S/S | 1 |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————