Can Dissolvable Bridge Plugs Replace Conventional Drillable Bridge Plugs?

As the target of oil and gas exploration and development gradually shifts to low-permeability and low-grade resources, the staged fracturing technology of horizontal wells has become an important means for reservoir stimulation and the effective increase of single good production. As one of the important downhole tools for staged fracturing, bridge plugs (such as Dissolvable Bridge Plugs) are increasingly widely used. At present, conventional bridge plugs include drillable bridge plugs and large-diameter bridge plugs. After fracturing, the drilling tool milling process of the drillable bridge plug is likely to cause downhole accidents and high operation and construction costs. At the same time, debris and operating fluids are likely to pollute the reservoir.

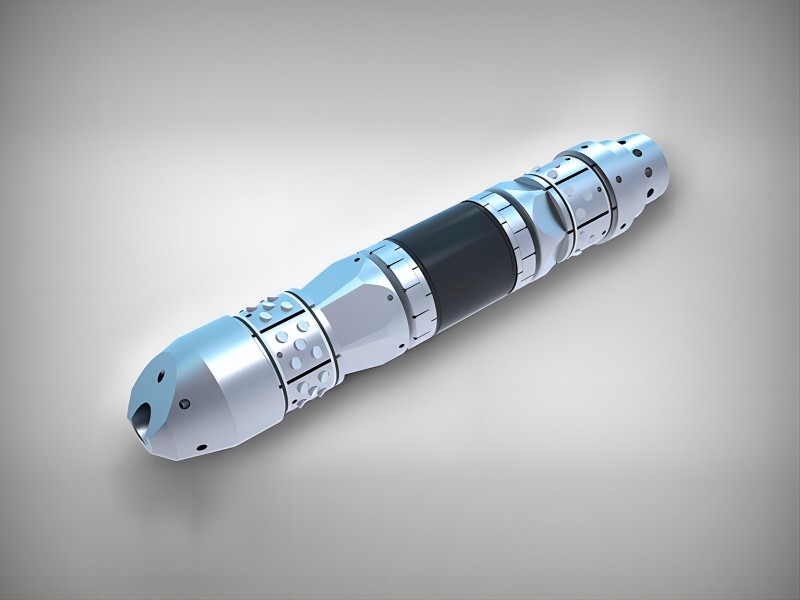

Features of dissolvable bridge plugs

The main body of the dissolvable bridge plug is made of lightweight and high-strength soluble alloy material, which has high strength and a pressure resistance of 70 MPa. It is soluble in water and the dissolution time is controllable. After the fracturing operation is completed, the dissolvable bridge plug chemically reacts with the liquid in the wellbore under high temperature and high-pressure environment and is discharged out of the wellbore with the flow back fluid after dissolution. The invention of this tool is a complete reversal of the conventional plug fracturing tool.

The cost of dissolvable bridge plugs

The cost of dissolvable bridge plugs is basically the same as that of imported composite bridge plugs. However, the follow-up treatment process of traditional bridge plugs has a long construction period and high operating costs. The use of soluble bridge plugs can greatly reduce the post-construction costs of fracturing operations. The dissolvable bridge plug can minimize the possibility of a midway setting. Even if it is stuck, the bridge plug can be melted through rapid processing technology to reduce the risk of an overhaul.

The temperature grades of dissolvable bridge plugs

The temperature grades of dissolvable bridge plugs include <50°C, 50-80°C, 80-120°C, and 120-160°C. There are 4 temperature levels in total. The formation temperature at this depth can be calculated according to the set depth, and the corresponding soluble bridge plug can be selected.

The material of dissolvable bridge plugs

The dissolvable bridge plug is made of soluble magnesium alloy material. It can meet the strength requirements under high temperatures and high pressure, and the product hardly decomposes in the clear water river guar gum solution. Dissolution can be controlled under different temperatures and different salinity conditions by adjusting the formula, the dissolution rate is proportional to the underground salinity and temperature, and the dissolved product is in the form of suspended powder, which is easy to flow back.

The test and use of dissolvable bridge plugs

The dissolvable bridge plug has passed the test of the test well. Under the condition of 75Mpa, it can bear the pressure for 24 hours without dropping the pressure. It has excellent sealing performance and fast dissolution speed. , can replace similar imported products.

dissolvable bridge plugs were applied to 7 horizontal wells in China Oilfield for staged fracturing. The maximum number of fracturing stages was 47. During the operation, the ball seat was set and sealed smoothly, and the pressure was stable. There was no obstruction in the position of the ball seat when the well was opened later and applied successfully. The field proved that the performance of the tool is reliable and meets the construction needs.