Overview

Air-driven chemical injection equipment is suitable for chemical additives injecting into oil and gas well bores, christmas tree and oil and gas pipelines during oil exploitation and transmission for plug removal, viscosity reduction, paraffin removal, rust removal, etc. This chemical injection skid is available to inject anti-frozen agent, viscosity reducer, blocking remover, biocide chemicals, oxygen scavenger, pour point disperant (PPD), anti-corrosion agent, etc.

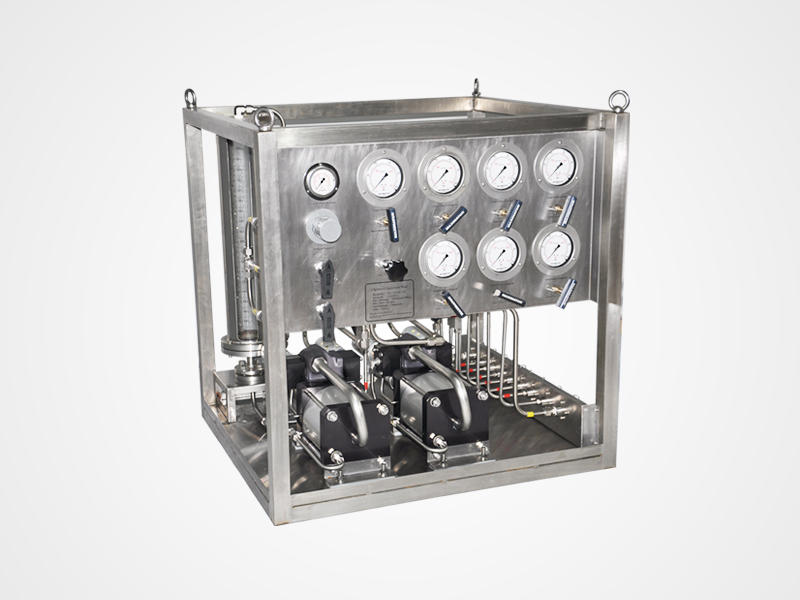

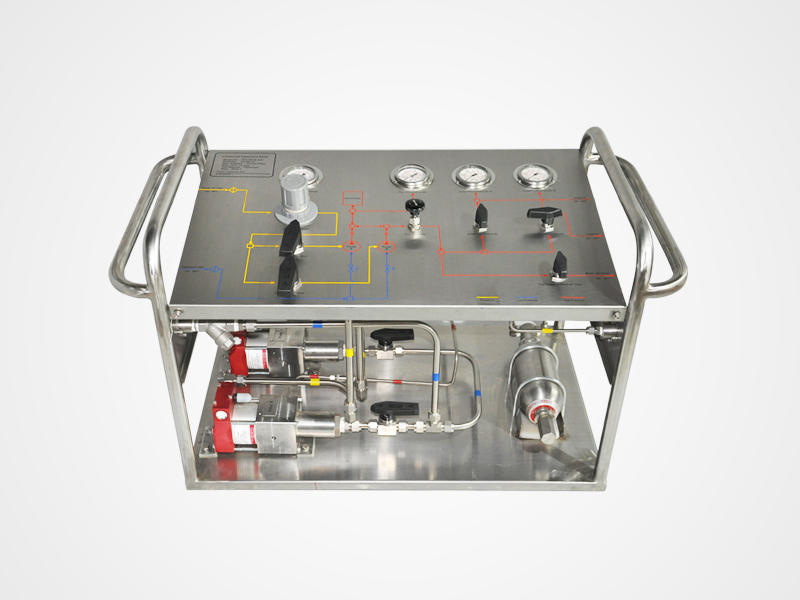

The pressure will be generated and boosted by means of a pneumatic hydraulic pump, which will be connected to the existing industrial compressed-air system at 6 to 12 bar. To make the air-operated chemical injection skid impact, we generally equipped single pump and dual pumps on skid(upon clients’ request).

Feature

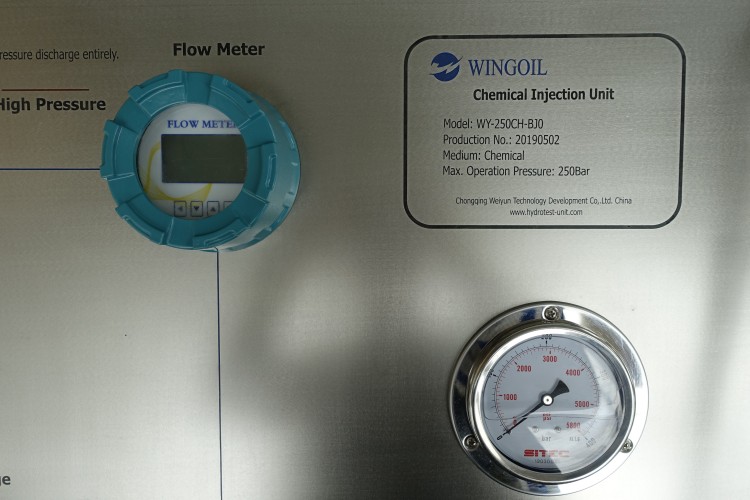

- With shockproof and dual scale display pressure gauge.

- Has operation schematic on the control panel, which is easy to observe and operate.

- Low-pressure compressed air as booster power source to keep convenience and safety.

- All components, piping and valves are made of 316s or 316L, which can prevent from corrosion effectively.

- Equipped with a glass column and high-precision flow control valve to meet the requirements of high flow rate chemical injection.

- Adopted pressure to be self-locked to adjust output pressure keeps constant in case of overshoot under air-driven pressure setting constant.

Model: WY-250CH-BJ0

| Chemicals | Anti-frozen agent, viscosity reducer, blocking remover, biocide chemicals, oxygen scavenger, pour point disperant (PPD), anti-corrosion agent |

| Pressure | 0 to 2000 bar / 29,000 PSI |

| Flow rate | 0 to 24L/min (customize) |

| Pressure accuracy | ±1%FS |

| Ambient temperature | -20℃ to 65℃ |

| Application | Surface low pressure, downhole high pressure |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————