Air Control Unloading Valve

- The special control valves of development, the seal inside between the ball and the metal, special structural design, and ball can make the pressure of low viscosity fluid is almost zero leakage. Relative to the air control valve has better impact resistance, and can be high frequency. With the combined use of 2/3 way Reversing valve, can actually pure mechanical type reaches the set pressure unloading.

Share to

Overview

The special type control valve developed by the pneumatic check valve Stark has a hard seal between the ball and the metal surface inside. The special structure of the valve core and the steel ball can make the low viscosity fluid pressure almost zero leakage. Compared with pneumatic needle valve, it has better impact resistance and can work at high frequency. It can be used in conjunction with the 2-position three-way pilot directional valve of Styker to realize the purely mechanical unloading at the set pressure. Hydraulic control check valve The hydraulic control check valve adopts a spring-loaded, leak-free ball valve structure. All parts are made of stainless steel and installed with standard valve plate; Oil ports: A and B are the oil ports of the actuator (main channel); Z is the control oil port; L is the leakage port (valve core inner chamber unloading); Application: As a one-way sealing element, it can be used in various unloading conditions and as a pulse pressure generator. Pneumatic ball valve seal: PTFE, PEEK, POM+metal temperature: – 40 to 200 ℃ caliber: DN10-25 pressure: 31.5MPa to 80MPa installation interface: thread, DIN2353 standard material: carbon steel, stainless steel media: applicable to water, oil, natural gas and other pure, impurity free media, media containing impurities need to be consulted separately. The manual control valve group is generally used for field control instruments to provide multiple channels for instruments, reduce installation workload and improve system reliability; Inlet and outlet: G1/4 “working pressure: maximum 60000 psi manual pressure generator drive medium: anti-wear hydraulic oil (No. 7-32) pressure range: 0 to 210MPa; maximum boost stroke: 80mm; calibration pressure accuracy: 0.1%; operating temperature: – 30 ℃ to 150 ℃ output interface: HF4 (9/16-18UNF) boost mode: manual

Features

- Check valve is suitable for blocking the passage of the medium in one direction and allowing the medium to be in the other direction without leakage under pressure. The combined metal plastic seat ensures the best sealing of gas and liquid.

- The check valve has good flow, high leak tightness, and reliability under low pressure and high pressure. The replaceable valve seat provides easy and cost-effective maintenance.

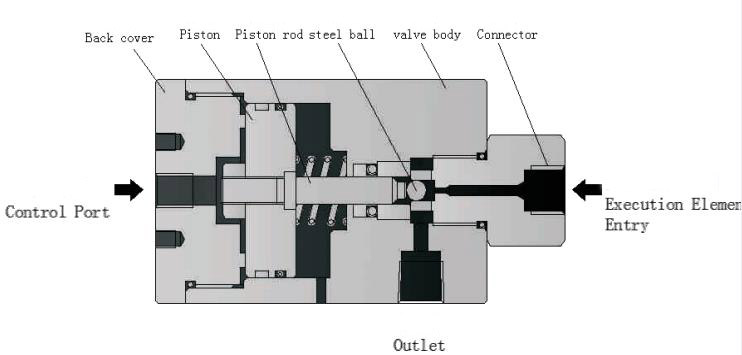

Pneumatic Check Valve

- The special control valve developed by Stark has a hard seal between ball and metal surface inside, and the special structure of valve core and steel ball can make low viscosity.

- The fluid pressure is almost zero leakage. Compared with pneumatic needle valve, it has better impact resistance and can work at high frequency.

- The two-position three-way pilot directional valve can be used together to realize the purely mechanical unloading at the set pressure.

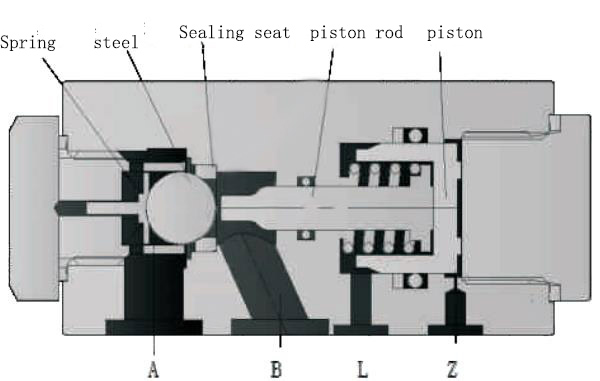

Hydraulic Control Check Valve

- The hydraulic control check valve adopts a spring-loaded, leak-free ball valve structure. All parts are made of stainless steel and installed with standard valve plate.

- Oil ports: A and B are the oil ports of the actuator (main channel); Z is the control oil port; L is the leakage port (valve core inner chamber unloading).

- Application: As a one-way sealing element, it can be used in various unloading conditions and as a pulse pressure generator.

Manual Control Valve Group

- Inlet and outlet: G1/4

- Max. Working pressure: 60,000 psi

- It is generally used for field control instruments to provide multiple channels for instruments, reduce installation workload and improve system reliability;

Manual Pressure Generator

- This product is completely open structure, full military sealing technology, long service life, no leakage, more convenient for maintenance; Unique secondary pressurization.

- The design makes the pressure rise and fall more stable, the pressure can be stabilized instantly, and the return calibration is very easy to operate, which is the pressure source for on-site calibration of pressure equipment.

- This machine provides pressure generation for the calibration of instruments, and is widely used for measurement and scientific research in laboratories and fields of electric power, metallurgy, petroleum, chemical industry, measurement system and other industries.

| Sealing | PTFE, PEEK, POM+metal |

| Temperature | – 40 to 200 ℃ |

| Diameter | DN10-25 |

| Pressure | 31.5 MPa to 80 MPa |

| Installation interface | Thread, DIN2353 standard |

| Material | Carbon steel, stainless steel |

| Medium | Applicable to water, oil, natural gas, and other pure, impurity-free media |

Note: Media containing impurities need to be consulted separately.

Pneumatic check valve

| Model | Drive pressure (bar) | Flow (CV) | Control port | Inlet | Outlet | Rated pressure (bar) |

| SX-02 | 5 | 0.12 | G1/8″ | NPT1/4″ | NPT1/4″ | 1000 |

Hydraulic control check valve

| Model | Flow (lpm) | Port pressure (bar) ABZ | Port pressure (bar) L | Control oil volume (cm³) | Weight (kg) | Connection mode |

| HCV-2 | 35 | 700 | Non-pressure return tank | 0.5 | 0.4 | Plate connection |

| HCV-3 | 50 | 500 | Non-pressure return tank | 0.5 | 0.7 | Plate connection |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————