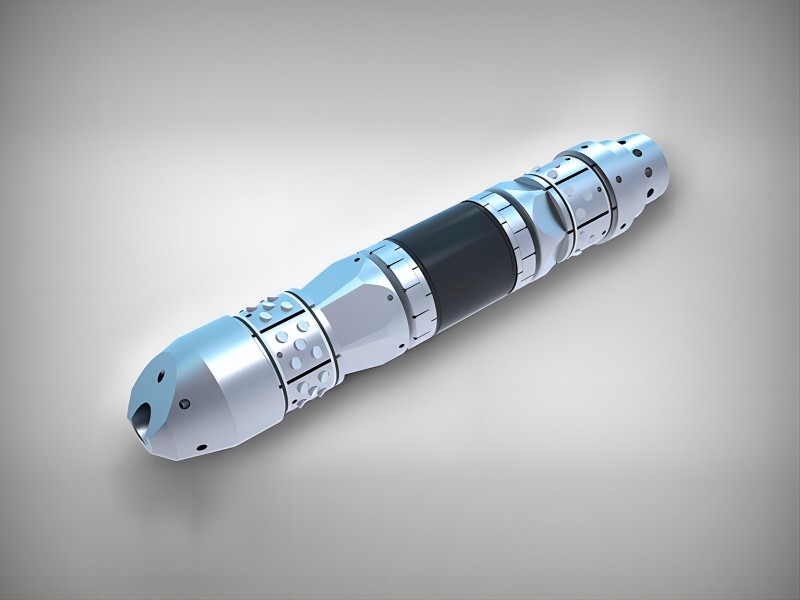

Advanced Downhole Tools for Oil and Gas in Fracturing Techniques

Oil and gas extraction is a vital part of the global energy supply, and hydraulic fracturing plays a key role in enhancing production. During hydraulic fracturing, downhole tools are essential for delivering fracturing fluids to the targeted formations and managing the process efficiently. This article delves into the critical role of these tools, focusing on frac balls, disintegrating frac plugs, and dissolvable frac plugs, and explores their applications in modern fracturing techniques.

Understanding What is Downhole Tools

Downhole tools refer to specialized equipment deployed within an oil or gas well to support drilling, completion, fracturing, and production operations. Their performance significantly impacts the efficiency, cost-effectiveness, and safety of well operations.

In hydraulic fracturing, downhole tools serve several key functions:

- Zonal isolation: Ensuring effective fluid delivery to the target formation by using tools that create isolation between different sections of the well.

- Fluid control: Regulating fluid flow through sealing mechanisms to optimize the fracturing process.

- Simplified post-fracturing operations: Innovations in downhole tools help minimize the need for intervention, reducing operational complexity and cost.

Types of Downhole Tools in Hydraulic Fracturing

The most commonly used downhole tools for hydraulic fracturing include:

- Frac Ball: A small, high-strength ball used for sealing and directing fluid flow during multi-stage fracturing.

- Disintegrating Frac Plug: A plug that disintegrates over time after fracturing is complete, eliminating the need for mechanical removal.

- Dissolvable Frac Plug: A plug made from materials that dissolve in downhole conditions, offering a fully degradable solution without requiring intervention.

The continuous advancement of these tools enhances the automation of hydraulic fracturing, reducing operational time and costs.

Frac Ball: An Essential Tool in Multi-Stage Fracturing

A frac ball is a spherical component used in multi-stage hydraulic fracturing. It is typically made from composite materials, metals, or dissolvable substances. Its working principle includes:

- Pumping the Frac Ball into the wellbore along with the fracturing fluid.

- The Frac Ball seats on a ball seat or sliding sleeve, creating a seal.

- The increased pressure forces fractures in the upper formation while isolating lower sections.

- After fracturing, some frac balls can be retrieved, while others dissolve or degrade.

Applications:

- Used in multi-stage fracturing to isolate different reservoir zones.

- Ideal for operations requiring quick transitions between fracturing stages.

Advantages:

- Simple design with relatively low cost.

- Effective for standard multi-stage fracturing operations.

- Some frac balls are made of dissolvable materials, reducing post-fracturing clean-up.

Limitations:

- Traditional Frac Balls require retrieval or milling, increasing operational costs.

- Performance may degrade under extreme downhole temperatures and pressures.

Disintegrating Frac Plug: Enhancing Efficiency in Hydraulic Fracturing

A disintegrating frac plug is a tool designed to provide temporary isolation during fracturing and then degrade over time without requiring milling or mechanical removal. These plugs are typically made from composite materials, metal-matrix composites, or ceramic-based substances.

Its working mechanism involves:

- Deployment into the wellbore, where it forms a seal for zonal isolation.

- Exposure to wellbore conditions such as temperature, pressure, and fluid composition, triggers gradual disintegration.

- Complete breakdown of the plug, restoring full wellbore access without intervention.

Advantages of Disintegrating Frac Plugs

- Increased operational efficiency: Eliminates the need for post-fracturing milling, reducing rig time and costs.

- Ideal for complex well conditions: Useful in extended-reach horizontal wells where retrieval is challenging.

- Minimizes operational risks: Reduces risks associated with milling and retrieval operations.

Limitations

The rate of disintegration varies depending on wellbore conditions, making precise control difficult.

Downhole fluids may affect the uniformity of disintegration, potentially leaving residues.

Dissolvable Frac Plug: A Fully Degradable Solution

A dissolvable frac plug is a specialized tool designed to degrade entirely in downhole conditions, eliminating the need for intervention. These plugs are typically made from magnesium alloys or polymer-based materials that react with wellbore fluids over time.

The dissolution mechanism is influenced by:

- Temperature: Higher temperatures accelerate degradation.

- Fluid composition: Salinity and chemical additives impact dissolution rates.

- Time: The material is engineered to dissolve within a predictable timeframe.

Advantages Over Traditional Frac Plugs

- No milling required: Eliminates the need for intervention, and reduces downtime.

- Minimal wellbore debris: Fully dissolves, preventing obstructions in the wellbore.

- Environmental benefits: Reduces the need for waste disposal, making operations more sustainable.

Application Scenarios and Challenges

Dissolvable Frac Plugs are widely used in multi-stage hydraulic fracturing, particularly in environmentally sensitive areas. However, challenges include:

- Material cost: Higher production costs compared to traditional plugs.

- Dissolution control: Requires precise engineering to ensure predictable degradation under varying well conditions.

Downhole Tools Technical Comparison and Selection

To better illustrate the characteristics of frac balls, disintegrating frac plugs, and dissolvable frac plugs, here is a detailed technical comparison:

| Comparison Item | Frac Ball | Disintegrating Frac Plug | Dissolvable Frac Plug |

| Structural Features | Solid sphere, simple structure | Special design, disintegrates under specific conditions | Made of dissolvable materials |

| Working Principle | Seals perforations by seating in a ball seat | Disintegrates autonomously under specific conditions | Dissolves gradually in wellbore fluids |

| Sealing Performance | Reliable, withstands high pressure | Good, stable sealing during fracturing | Meets fracturing requirements, but mechanical performance is limited |

| Operational Efficiency | Easy to operate, but may affect subsequent operations | Eliminates retrieval, improving efficiency | Eliminates retrieval, simplifying procedures |

| Environmental Performance | May cause contamination if left in the wellbore | No solid waste after disintegration | Completely dissolves, high environmental performance |

| Cost | Relatively low cost | Higher material costs | Higher R&D and production costs |

In different geological and operational conditions, selecting the appropriate downhole tool requires considering multiple factors. For simple geological conditions with a larger wellbore diameter and cost sensitivity, frac balls may be an economical choice. For deep formations or complex geology where retrieval is difficult, disintegrating frac plugs offer significant advantages. In highly regulated environmental areas such as offshore fields, dissolvable frac plugs provide the best long-term benefits despite their higher costs.

In Summary

As the oil and gas industry advances towards greater efficiency, environmental sustainability, and cost-effectiveness, the innovation of downhole tool technology will continue. Frac balls, disintegrating frac plugs, and dissolvable frac plugs each provide unique solutions for diverse well conditions. Future developments in material science and intelligent technologies will further optimize fracturing operations, enhancing the sustainability of energy development.