6 Applications of High Pressure Hydrogen Shut-off Valve

With the global push towards sustainable and cleaner energy sources, hydrogen has emerged as a key player in the energy landscape. Its potential to reduce carbon emissions and contribute to cleaner industrial processes makes it an attractive solution for various industries. Central to hydrogen’s safe and efficient use is the high-pressure hydrogen shut-off valve. This specialized valve plays a critical role in controlling and regulating the flow of hydrogen gas under high pressure, ensuring safety and functionality in systems that rely on hydrogen as a fuel or raw material. This article will discuss the importance and applications of high-pressure hydrogen shut-off valves in various sectors.

1. Application in Fuel Cell Systems

Fuel cell electric vehicles (FCEVs) are gaining traction as a sustainable alternative to traditional internal combustion engines. These vehicles use hydrogen to generate electricity through fuel cells. A critical component of this system is the high-pressure hydrogen shut-off valve, which ensures efficient and safe control of hydrogen flow. Here’s how it functions:

1) Hydrogen Flow Control:

- Manages the hydrogen flow from storage tanks to the fuel cell stack.

- Hydrogen is stored at extremely high pressures, often exceeding 700 bar (10,000 psi).

- The valve regulates the release of hydrogen at a controlled rate to prevent overpressure, ensuring fuel cells receive the proper amount for safe and efficient operation.

2) Safety Mechanism:

- Automatically shuts off the hydrogen flow when the vehicle is turned off or in emergency situations.

- Prevents unwanted hydrogen leaks, reducing the risk of accidents given hydrogen’s highly flammable nature.

3) Pressure Management:

- Maintains correct pressure levels to protect the fuel cell stack and other components from potential damage caused by overpressure.

2. Application in Hydrogen Storage Systems

Hydrogen storage is a critical aspect for industries utilizing hydrogen as a fuel or raw material. High-pressure hydrogen shut-off valves play an essential role in maintaining safety and efficiency in hydrogen storage systems. Here’s how they contribute:

1) Hydrogen Release Control:

- Regulates the release of hydrogen from high-pressure storage tanks.

- Ensures efficient containment and prevents unintended hydrogen flow during normal operation.

2) Overpressure Prevention:

- Designed to detect abnormal pressure conditions within the storage system.

- Automatically shuts off when overpressure is detected to prevent tank rupture or leakage.

3) Leak Prevention:

- Hydrogen molecules are small and prone to leaking through microscopic openings.

- Shut-off valves often feature advanced sealing materials and designs to minimize leakage even under high-pressure or extreme conditions.

4) Durability in Extreme Conditions:

- Built with advanced materials to withstand long-term exposure to high-pressure conditions.

- Critical in industries where hydrogen is stored for prolonged periods, helping prevent degradation of storage systems.

3. Application in Hydrogen Refueling Stations

As hydrogen refueling infrastructure grows globally, high-pressure hydrogen shut-off valves are integral to the safe and efficient operation of hydrogen refueling stations. Here’s how these valves function in refueling stations:

1) Flow Control:

- Regulates the flow of hydrogen from high-pressure storage tanks to vehicle tanks.

- Ensures hydrogen is dispensed at the correct pressure and rate, preventing overfilling or overpressurization.

2) Overpressurization Prevention:

- Monitors and manages pressure levels during refueling to avoid tank damage or hazardous situations.

- Essential for protecting both the vehicle’s tank and the refueling system.

3) Emergency Shutdown:

- Designed to rapidly cut off hydrogen flow in emergencies, such as fires or equipment malfunctions.

- Protects personnel, vehicles, and equipment from potential hazards by stopping gas flow instantly.

4) Automated Monitoring Systems:

- Many stations feature automated pressure monitoring systems that trigger the shut-off valve when abnormalities are detected.

- This automation ensures a quick response, further enhancing safety during refueling operations.

4. Application in Industrial Hydrogen Production

In large-scale hydrogen production, precise control of hydrogen flow and pressure is crucial for operational efficiency and safety. High-pressure hydrogen shut-off valves play a vital role in industrial hydrogen production by:

1) Flow Regulation:

- Controls the flow of hydrogen in pipelines and equipment, ensuring steady and optimal production rates.

- Prevents excessive hydrogen release, which could cause disruptions or accidents.

2) Stable Pressure Maintenance:

- Keeps pressure levels consistent throughout the system to prevent production interruptions.

- Helps maintain a safe operating environment by managing high-pressure hydrogen flow.

3) System Isolation:

- Enables rapid isolation of parts of the hydrogen system during maintenance or in response to abnormal conditions.

- This ability to isolate areas without shutting down the entire system minimizes downtime and enhances operational productivity.

4) Operational Continuity:

- By controlling flow and isolating sections of the system, shut-off valves ensure that hydrogen production can continue safely without unnecessary interruptions.

- Contributes to maintaining high efficiency and reducing production costs.

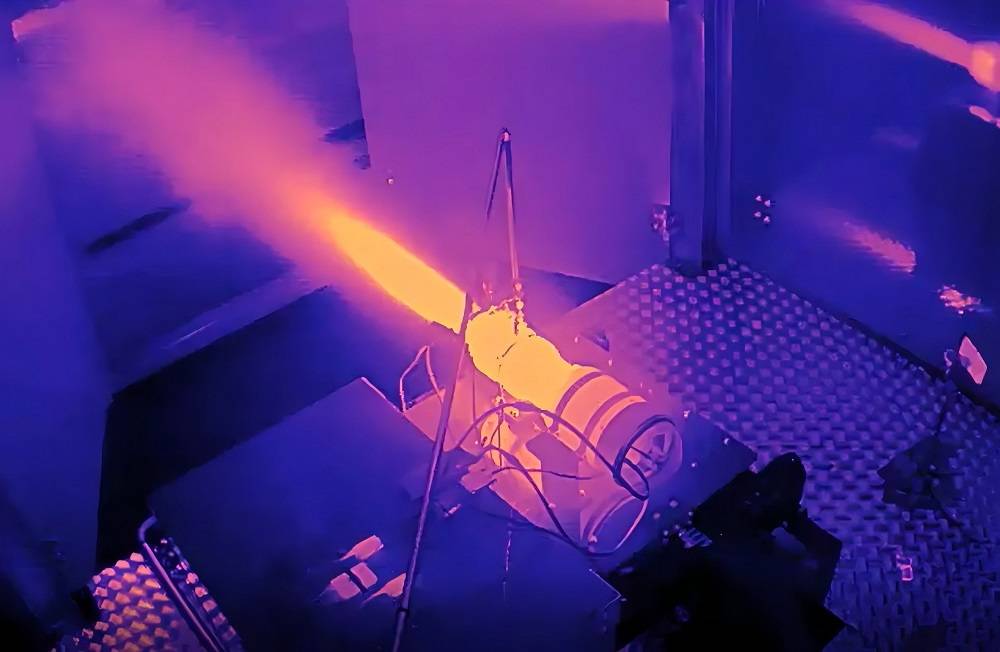

5. Aerospace Applications

Hydrogen plays a vital role in the aerospace sector, especially in rocket propulsion systems. High-pressure hydrogen shut-off valves are essential for controlling fuel flow in various aerospace applications. Here’s how they are utilized:

1) Rocket Propulsion:

- Regulates the flow of liquid hydrogen to rocket engines during launches.

- Ensures smooth and efficient delivery of hydrogen for successful liftoff.

- Handles extreme conditions, including rapid pressure changes, high temperatures, and intense vibrations.

- Any failure or malfunction could have catastrophic consequences, making valve reliability critical.

2) Precision Control:

- Maintains stable hydrogen flow before and during launch to ensure optimal engine performance.

- Crucial to manage the fuel supply to prevent disruptions that could impact the flight.

3) Aerospace Research:

- Used in wind tunnel testing, where controlled hydrogen flow at high pressures simulates flight conditions.

- Allows researchers to replicate real-world scenarios, improving the safety and performance of aerospace technologies.

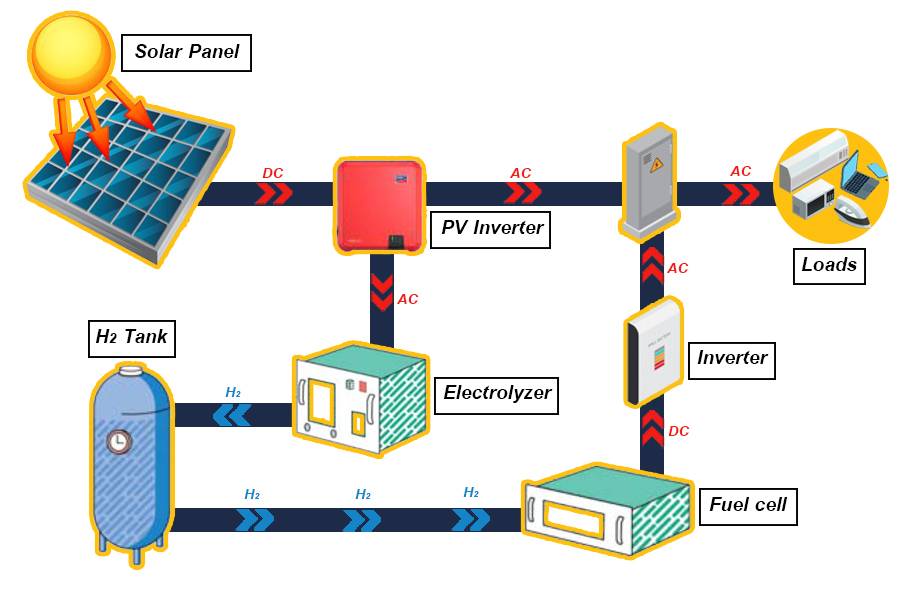

6. Application in Renewable Energy Storage Systems

Hydrogen is increasingly being used in renewable energy storage systems as a method of storing excess energy produced by renewable sources such as wind and solar. High-pressure hydrogen shut-off valves are instrumental in managing the hydrogen storage and release processes. Key applications include:

1) Hydrogen Compression and Storage:

- Controls the flow of hydrogen into large storage tanks.

- Ensures hydrogen is safely compressed and stored at high pressure for later use.

2) Energy Generation:

- Manages the release of stored hydrogen when energy is needed.

- The valve regulates the flow of hydrogen to fuel cells or turbines, ensuring smooth conversion back into electricity.

3) Overpressure Prevention:

- Prevents overpressurization during hydrogen compression, protecting tanks and storage systems from damage.

- Maintains optimal pressure to ensure hydrogen is stored safely and efficiently.

4) Efficiency and Reliability:

- Enhances the efficiency of the energy storage process by maintaining correct pressure levels.

- Optimizes hydrogen storage for future energy use, contributing to the reliability and viability of renewable energy systems.

The above application examples demonstrate the importance of high-pressure hydrogen shut-off valves in ensuring the safety and efficiency of hydrogen related industrial processes. When designing and selecting materials for valves, it is necessary to consider the special physical and chemical properties of hydrogen, such as low density and high ignition points, to ensure long-term reliability and safety.