3 Characteristics of Lubricating Oil for Oilfield Equipment

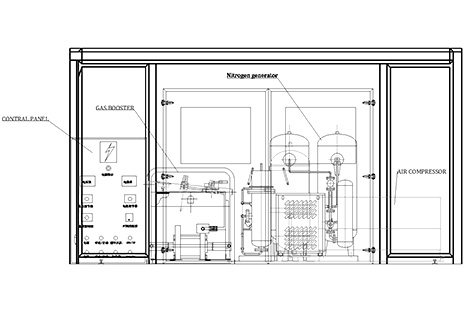

In the process of oil field development and oil production, there are many kinds of oilfield equipment used. But the machinery and equipment using lubricating oil are mainly used in water injection pumps, oil pipelines, and oil pumping equipment, and the amount of lubricating oil used is very large, in the above 3 Among the various types of equipment, oil pumping equipment is used the most.

According to statistics, in the national oilfield equipment, the amount of lubricating oil used by pumping units has reached 200,000 tons, which is equivalent to the annual production capacity of a large lubricating oil factory. In addition, oilfield equipment mostly works in the field, and the working environment is very harsh. They will not only be exposed to wind and sun but also be attacked by sand and dust. Therefore, the requirements for lubricating oil are very high. Therefore, a detailed evaluation of the performance characteristics and application status of lubricating oil used in oilfield equipment will be helpful to the use the oilfield service equipment.

Characteristics of oil used in oilfield equipment

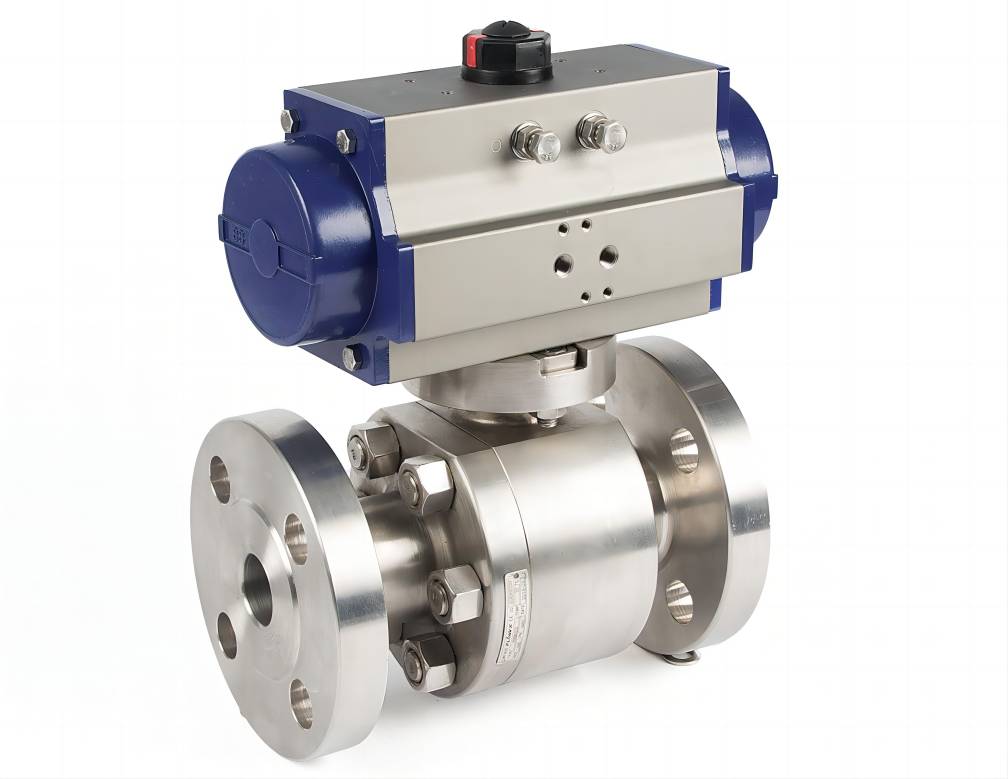

Lubricating oil is extracted from petroleum and is widely used in oilfield equipment to achieve the effect of reducing the friction of parts during mechanical operation. It is an intensive product, and its main functions are protection, insulation, cooling, etc. The more common lubricating oils are bearing oils, gear oils, and hydraulic oils. The main properties can be reflected by lubricity, viscosity index, anti-oxidation, and other indicators.

Viscosity Index of oil used in oilfield equipment

The level of the viscosity index reflects the fluidity of the lubricating oil. If the viscosity index of the lubricating oil is high, the fluidity of the lubricating oil will be very strong. On the contrary, the fluidity of the lubricating oil will be weak. Among them, lubricating oil with strong fluidity is more suitable for use in low-speed operation or heavy-duty oilfield equipment. As mentioned above, the working environment of oilfield equipment is very harsh, and the oilfield equipment runs for a long time, the load is very large, and it is also easy to damage. Therefore, due to various considerations, the lubricating oil used in oilfield equipment needs to have strong fluidity, to meet high-intensity use and adapt to the invasion of field conditions, to ensure the working efficiency of oilfield equipment.

High lubricity of oil used in oilfield equipment

The lubricity of lubricating oil is the performance of reducing friction, which is also the most fundamental performance of lubricating oil. In the protection of oilfield equipment, lubricating oil is a very important protection measure, and it also provides a guarantee for the high-speed operation of oilfield equipment. Due to the relatively large load of oilfield equipment, the impact force is also large and small for a while. Therefore, this oilfield equipment must not only use lubricating oil with strong fluidity but also lubricating oil with relatively high lubricity. If the lubricity is high, the resistance between parts in the oilfield equipment can be effectively reduced, and energy saving can be achieved to a certain extent. Therefore, no matter in terms of work efficiency or energy saving, it is necessary to strengthen the lubricity of lubricating oil.

Anti-oxidation of oil used in oilfield equipment

In oil extraction, oilfield equipment is prone to corrosion. Some lubricating oils will produce some small particles after contact with air, which will reduce the performance of the oilfield equipment. Therefore, the lubricating oil used in oilfield equipment needs to meet a certain anti-oxidation ability, not only for air but also for metal catalysis ability. Therefore, oilfield equipment needs to be met at the same time. The above three requirements can make the oilfield equipment operate better, improve work efficiency, and achieve the effect of energy saving and emission reduction.